Abstract

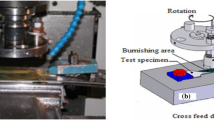

The paper presents a brief review of innovative applications on burnishing, followed by analysis on results obtained during the combined burnishing process, while experimenting on low-carbon steels using Taguchi’s methodologies. The experiments were performed using spindle speed, feed rate and number of passes as the process parameters; while surface roughness and surface micro hardness were the response parameters. The results indicate that roller burnished specimens gave optimum results in terms of surface roughness measurements upto 0.21 Ra (roughness average in µm). The developed novel process had both ball and roller burnishing tools embedded in one single set-up; which improved the utility and enhanced surface hardness as compared to the single-burnished specimens. Improvements in the surface finish with respect to ball burnished surfaces were evidenced; which is further illustrated in the paper. The surfaces thus produced had an added advantage of both roller and ball burnishing process in a single operation, making it chip-less and sustainable process. In the experimental conditions, the best surface finish using combined burnishing tool was of the order of 0.35 Ra (roughness average in µm) and surface micro hardness was 77HRc (hardness Rockwell). The investigations on micro structures produced on the burnished surfaces did not indicate any phase related changes.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Deepak, M., & Ravindra, T. (2013). A review on ball burnishing process. Journal of Scientific and Research Publications, 3(4), 1–2.

Pavan, K., & Purohit, G. K. (2013). Design and development of ball burnishing tool. International Journal of Engineering Research and Technology, 6(2), 733–738.

Luo, L., Lijiyang, W., Jianying, L., & Qunpeng, Z. (2005). Investigations of the burnishing process with PCD tool on non-ferrous metals. International Journal of Advanced Manufacturing Technology, 25, 454–459.

Jawalkar, C. S., & Walia, R. S. (2009). Study of Roller Burnishing process on En-8 specimens using Design of Experiments. Journal of Mechanical Engineering and Research, 1(1), 39–46.

Shneider, Yu. G. (1967). Characteristics of the burnished components. Mech. Tooling Journal, 38, 19–22.

Degarmo Paul, E., Black, J., & Kohser (2005). Materials and processes in engineering, 8th ed. (pp. 1096–1112). Prentice Hall of India.

Loh, N. H., Tam, S. C., & Miyazawa, S. (1991). Investigations on the surface roughness produced by ball burnishing. International Journal of Machine Tools Manufacturing, 31(1), 75–81.

Fu, C. H., Sealya, M. P., Guo, Y. B., & Weib, X. T. (2014). Austenite–martensite phase transformation of biomedical Nitinol by ball burnishing. Journal of Materials Processing Technology, 214, 3122–3130.

Hiegemann, L., Weddeling, C., Ben, K. N., & Tekkaya, A. E. (2015). Prediction of roughness after ball burnishing of thermally coated surfaces. Journal of Materials Processing Technology, 217, 193–201.

Murthy, R. L., & Kotiveerachary, B. (1981). Burnishing of metallic surfaces—A review. Precision Engineering Journal, 3, 172–179.

Hassan, A. M. (1997). The effects of ball and roller burnishing on the surface roughness and hardness of some nonferrous metals. Journal of Materials Processing Technology, 72, 385–391.

Mieczyslaw, K., & Andrzej, P. (2010). Center- less burnishing and influence of its parameters on machining effects. Journal of Materials Processing Technology, 1217–23.

El-Tayeb, N. S. M., Low, K. O., & Brevern, P. V. (2009). On the surface and tribological characteristics of burnished cylindrical Al-6061. Tribology International, 42, 320–326.

Walia, R. S., & Sandeep, K. (2007). Optimization of surface finishing conditions in roller burnishing. Master’s Thesis, Punjab Engineering College, Chandigarh.

Oksanen, J., Timo, H. J., Tervakangas, S., Laakso, P., Kilpi, L., Ronkainen, H., & Koskinen, J. (2014). Tribological properties of Ta-C at elevated temperature. Tribology International, 70, 94–103.

Shu, Y., Dillon, O., Puleo, D., & Jawahir, I. S. (2013). Effect of cryogenic burnishing on surface integrity modifications of Co-Cr-Mo biomedical alloy. Journal of Biomedical Materials Research Part B Applied Biomaterials, 101B(1). https://doi.org/10.1002/jbm.b.32827

EI-Khabeery, M. M., & EI-Axir, M. H. (2003). Experimental techniques for studying the effects of milling roller burnishing parameters on surface integrity. International Journal of Machine Tools and Manufacture, 42, 1705–1719.

Shiou, F. J., & Chang, C. H. (2008). Ultra precision surface finish of NAK 80 mould tool steel using sequential ball burnishing and ball polishing. Journal of Materials Processing Technology, 205(1–3, 26), 249–258.

Wojciech, K., & Krzysztof, N. (2016), Laser method based on imaging and analysis of scattered light used for assessment of cylindrical surfaces after dynamic burnishing process. International Journal of Surface science and Engineering. 10(1), 55.

Buldum, B., & Cagan, S. (2018). Study of ball burnishing process on the surface roughness and microhardness of AZ91D alloy. Experimental Techniques, 42, 233–241.

Trung-Thanh, N., Cao, L.-H., Dang, X.-P., Nguyen, T.-A., & Trinh, Q.-H. (2019). Multi-objective optimization of the flat burnishing process for energy efficiency and surface characteristics. Materials and Manufacturing Processes, 34(16), 1888–1901.

Amini, R. T. S. (2019). Analytical modeling of ultrasonic surface burnishing process: Evaluation of through depth localized strain. International Journal of Mechanical Sciences, 151, 118–132.

Liu, Z., Yang, M., & Deng, J. (2020). A predictive approach to investigating effects of ultrasonic-assisted burnishing process on surface performances of shaft. International Journal of Advanced Manufacturing Technology, 106, 4203–4219.

Walpole Ronald. (2005). Statistics and probability for engineers and scientists. Pearson Publications.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Jawalkar, C.S. (2021). Development and Analysis of Sustainable and Innovative Surface Finishing Process Through Combined Effects of Ball and Roller Burnishing. In: Agrawal, R., Jain, J.K., Yadav, V.S., Manupati, V.K., Varela, L. (eds) Recent Advances in Smart Manufacturing and Materials. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-3033-0_16

Download citation

DOI: https://doi.org/10.1007/978-981-16-3033-0_16

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-3032-3

Online ISBN: 978-981-16-3033-0

eBook Packages: EngineeringEngineering (R0)