Abstract

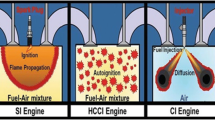

Conventional compression ignition (CI) engines have higher efficiency compared to spark ignition (SI) engines because of their higher compression ratio. Hence, they have been widely used for heavy-duty applications. However, CI engines tend to suffer from high tailpipe emissions of nitrogen oxides (NOx) and particulate matter (PM, also known as soot). CI engines control these emissions using advanced engine exhaust after-treatment devices or adopting a high level of exhaust gas recirculation (EGR), which are expensive and increase the system complexity. CI engines power approximately 75% of heavy-duty vehicles in USA. These numbers are even higher for Asian countries. United States Environmental Protection Agency (USEPA) aims for 90% reduction in NOx levels from heavy-duty engines by 2024. Thus, it becomes essential to replace the CI engines in heavy-duty vehicles with advanced engine combustion technologies to comply with strict emission norms being adopted in future. Gasoline compression ignition (GCI) is advanced and promising low-temperature combustion (LTC) technology, which takes advantage of higher volatility and auto-ignition temperature of gasoline-like fuels and higher compression ratio inherent to diesel engines. It has potential to reduce PM and NOx emissions simultaneously without compromising with CI engine like efficiency. However, practical implementation of GCI technology in heavy-duty applications is a challenging task. Some of these challenges associated are higher combustion loss and combustion instability at lower engine loads, combustion noise at higher engine loads, difficulty in maintaining a balance between maximum pressure rise rate, higher CO and HC emissions, etc. Therefore, particular emphasis is given on addressing various challenges and their possible solutions to adapting GCI combustion technology in heavy-duty vehicles. First part of the chapter focuses on the need for introduction of advanced combustion technology in heavy-duty automotive sector. Thereafter, comprehensive literature on application of GCI technology for heavy-duty engine applications is summarized.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Abbreviations

- CI:

-

Compression ignition

- SI:

-

Spark ignition

- LOF:

-

Low octane fuel

- HDV:

-

Heavy-duty vehicle

- PRF:

-

Primary reference fuel

- HCCI:

-

Homogenous charge compression ignition

- PM:

-

Particulate matter

- NOx:

-

Oxides of nitrogen

- RCCI:

-

Reactivity controlled compression ignition

- EGR:

-

Exhaust gas recirculation

- HC:

-

Hydrocarbon

- PRF:

-

Primary reference fuel

- RON:

-

Research octane number

- CN:

-

Cetane number

- CO:

-

Carbon monoxide

- CA:

-

Crank angle

- bTDC:

-

Before top dead center

- aTDC:

-

After top dead center

- PRR:

-

Pressure rise rate

- GSA:

-

Global sensitivity analysis

- FIP:

-

Fuel injection pressure

- IVCT:

-

Intake valve closing time

- TDC:

-

Top dead center

- BTE:

-

Brake thermal efficiency

- WTW:

-

Well-to-wheel

- PCCI:

-

Premixed charge compression ignition

- CR:

-

Compression ratio

- PFS:

-

Partial fuel stratification

- MFS:

-

Medium fuel stratification

- HFS:

-

Heavy fuel stratification

- LTC:

-

Low-temperature combustion

- aHRR:

-

Apparent heat release rate

- dB:

-

Decibel

- DPF:

-

Diesel particulate filter

- TWC:

-

Three-way catalyst

- SOI:

-

Start of injection

- FIP:

-

Fuel injection pressure

- MPRR:

-

Maximum pressure rise rate

- GPF:

-

Gasoline particulate filter

- HFR:

-

Hydraulic fluid rates

- HCB:

-

Hydrogenated catalytic biodiesel

- FN:

-

Flow number

- EID:

-

Engine ignition delay

- BTE:

-

Break thermal efficiency

References

Leach, F., Kalghatgi, G., Stone, R., & Miles, P. (2020). The scope for improving the efficiency and environmental impact of internal combustion engines. Transportation Engineering, 100005.

Mobil, E. (2013). The outlook for energy: A view to 2040. Exxon Mobil, 6.

World Economic Forum. (2016). Available from: https://www.weforum.org/agenda/2016/04/the-number-of-cars-worldwide-is-set-to-double-by-2040.

Agarwal, A. K., Singh, A. P., & Maurya, R. K. (2017). Evolution, challenges and path forward for low temperature combustion engines. Progress in Energy and Combustion Science, 61, 1–56.

Singh, A. P., & Agarwal, A. K. (2019). Characteristics of particulates emitted by ic engines using advanced combustion strategies. In Advanced Engine Diagnostics (pp. 57–71). Singapore: Springer. https://doi.org/10.1007/978-981-13-3275-3_4.

Kalghatgi, G., & Johansson, B. (2018). Gasoline compression ignition approach to efficient, clean and affordable future engines. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 232(1), 118–138. https://doi.org/10.1177/0954407017694275.

U.S Energy Information Administration. (2019). Refining process. https://www.eia.gov/energyexplained/oil-and-petroleum-products/refining-crude-oil-the-refining-process.php.

Hildingsson, L., Kalghatgi, G., Tait, N., Johansson, B., & Harrison, A. (2009). Fuel octane effects in the partially premixed combustion regime in compression ignition engines (No. 2009–01–2648). SAE Technical Paper. https://doi.org/10.4271/2009-01-2648.

Jiang, C., Li, Z., Liu, G., Qian, Y., & Lu, X. (2019). Achieving high efficient gasoline compression ignition (GCI) combustion through the cooperative-control of fuel octane number and air intake conditions. Fuel, 242, 23–34.https://doi.org/10.1016/j.fuel.2019.01.032.

Yang, H., Shuai, S., Wang, Z., & Wang, J. (2013). Fuel octane effects on gasoline multiple premixed compression ignition (MPCI) mode. Fuel, 103, 373–379. https://doi.org/10.1016/j.fuel.2012.05.016.

Wang, H., Zhu, H., Ma, T., & Yao, M. (2020). Numerical investigation on low octane gasoline-like fuel compression ignition combustion at high load. Fuel, 270, 117532. https://doi.org/10.1016/j.fuel.2020.117532.

Lu, Z., Han, J., Wang, M., Cai, H., Sun, P., Dieffenthaler, D., Gordillo, V., Monfort, J.C., He, X., & Przesmitzki, S. (2016). Well-to-wheels analysis of the greenhouse gas emissions and energy use of vehicles with gasoline compression ignition engines on low octane gasoline-like fuel. SAE International Journal of Fuels and Lubricants, 9(3), 527–545. https://doi.org/10.4271/2016-01-2208.

Chang, J., Kalghatgi, G., Amer, A., Adomeit, P., Rohs, H., & Heuser, B. (2013). Vehicle demonstration of naphtha fuel achieving both high efficiency and drivability with EURO6 engine-out NOx emission. SAE International Journal of Engines, 6(1), 101–119. https://doi.org/10.4271/2013-01-0267.

Bae, C., & Kim, J. (2017). Alternative fuels for internal combustion engines. Proceedings of the Combustion Institute, 36(3), 3389–3413. https://doi.org/10.1016/j.proci.2016.09.009.

Chang, J., Kalghatgi, G., Amer, A., & Viollet, Y. (2012). Enabling high efficiency direct injection engine with naphtha fuel through partially premixed charge compression ignition combustion (No. 2012–01–0677). SAE Technical Paper. https://doi.org/10.4271/2012-01-0677.

Wang, B., Yang, H. Q., Shuai, S. J., Wang, Z., He, X., Xu, H. & Wang, J. (2013). Numerical resolution of multiple premixed compression ignition (MPCI) mode and partially premixed compression ignition (PPCI) mode for low octane gasoline (No. 2013–01–2631). SAE Technical Paper. https://doi.org/10.4271/2013-01-2631.

Mao, B., Chen, P., Liu, H., Zheng, Z., & Yao, M. (2018). Gasoline compression ignition operation on a multi-cylinder heavy duty diesel engine. Fuel, 215, 339–351. https://doi.org/10.1016/j.fuel.2017.09.020.

Zou, X., Liu, W., Lin, Z., Wu, B., & Su, W. (2018). An experimental investigation of the effects of fuel injection strategy on the efficiency and emissions of a heavy-duty engine at high load with gasoline compression ignition. Fuel, 220, 437–445. https://doi.org/10.1016/j.fuel.2018.02.035.

Paz, J., Staaden, D., & Kokjohn, S. (2018). Gasoline compression ignition operation of a heavy-duty engine at high load (No. 2018–01–0898). SAE Technical Paper. https://doi.org/10.4271/2018-01-0898.

Dempsey, A. B., Curran, S. J., & Wagner, R. M. (2016). A perspective on the range of gasoline compression ignition combustion strategies for high engine efficiency and low NOx and soot emissions: Effects of in-cylinder fuel stratification. International Journal of Engine Research, 17(8), 897–917. https://doi.org/10.1177/1468087415621805.

Zhao, F., Asmus, T. N., Assanis, D. N., Dec, J. E., Eng, J. A., & Najt, P. M. (2003). Homogeneous charge compression ignition (HCCI) engines (No. PT-94). SAE Technical Paper.

Hanson, R., Splitter, D., & Reitz, R. D. (2009). Operating a heavy-duty direct-injection compression-ignition engine with gasoline for low emissions (No. 2009–01–1442). SAE Technical Paper. https://doi.org/10.4271/2009-01-1442.

Zhang, F., Xu, H., Zhang, J., Tian, G., & Kalghatgi, G. (2011). Investigation into light duty dieseline fuelled partially-premixed compression ignition engine. SAE International Journal of Engines, 4(1), 2124–2134. https://doi.org/10.4271/2011-01-1411.

Zhang, Y., Zhan, L.,He, Z., Jia, M., Leng, X., Zhong, W., Qian, Y., & Lu, X. (2019). An investigation on gasoline compression ignition (GCI) combustion in a heavy-duty diesel engine using gasoline/hydrogenated catalytic biodiesel blends. Applied Thermal Engineering, 160, 113952. https://doi.org/10.1016/j.applthermaleng.2019.113952.

Noh, H. K., No, S. Y. (2017). Effect of bioethanol on combustion and emissions in advanced CI engines: HCCI, PPC and GCI mode–A review. Applied Energy, 208, 782–802. https://doi.org/10.1016/j.apenergy.2017.09.071.

Yang, B., Yao, M., Zheng, Z., & Yue, L. (2015). Experimental investigation of injection strategies on low temperature combustion fuelled with gasoline in a compression ignition engine. Journal of Chemistry https://doi.org/10.1155/2015/207248.

Wang, B., Wang, Z., Shuai, S., & Xu, H. (2015). Combustion and emission characteristics of Multiple Premixed Compression Ignition (MPCI) mode fuelled with different low octane gasolines. Applied Energy, 160, 769–776. https://doi.org/10.1016/j.apenergy.2015.01.115.

Yao, M., Zheng, Z., & Liu, H. (2009). Progress and recent trends in homogeneous charge compression ignition (HCCI) engines. Progress in Energy and Combustion Science, 35(5), 398–437. https://doi.org/10.1016/j.pecs.2009.05.001.

Borgqvist, P., Tunestal, P., & Johansson, B. (2013). Comparison of negative valve overlap (NVO) and rebreathing valve strategies on a gasoline PPC engine at low load and idle operating conditions. SAE International Journal of Engines, 6(1), 366–378. https://doi.org/10.4271/2013-01-0902.

Hunicz, J., (2014). An experimental study of negative valve overlaps injection effects and their impact on combustion in a gasoline HCCI engine. Fuel, 117, 236–250. https://doi.org/10.1016/j.fuel.2013.09.079.

Vallinayagam, R., AlRamadan, A. S., Vedharaj, S., An, Y., Sim, J., Chang, J., & Johansson, B. (2018). Low load limit extension for gasoline compression ignition using negative valve overlap strategy (No. 2018–01–0896). SAE Technical Paper. https://doi.org/10.4271/2018-01-0896.

Zhou, L., Hua, J., Wei, H., & Han, Y. (2019). An experimental investigation on low load combustion stability and cold-firing capacity of a gasoline compression ignition engine. Engineering, 5(3), 558–567. https://doi.org/10.1016/j.eng.2018.12.010.

Lawler, B., Lacey, J., Güralp, O., Najt, P., & Filipi, Z. (2018). HCCI combustion with an actively controlled glow plug: The effects on heat release, thermal stratification, efficiency, and emissions. Applied Energy, 211, 809–819. https://doi.org/10.1016/j.apenergy.2017.11.089.

Goyal, H., Kook, S., & Ikeda, Y. (2019). The influence of fuel ignition quality and first injection proportion on gasoline compression ignition (GCI) combustion in a small-bore engine. Fuel, 235, 1207–1215. https://doi.org/10.1016/j.fuel.2018.08.090.

Torregrosa, A. J., Broatch, A., Novella, R., Gomez-Soriano, J., & Mónico, L. F. (2017). Impact of gasoline and Diesel blends on combustion noise and pollutant emissions in Premixed Charge Compression Ignition engines. Energy, 137, 58–68. https://doi.org/10.1016/j.energy.2017.07.010.

Zhu, Y. W., Zhu, F. W., Zhang, Y. S., & Wei, Q. G. (2017). The research on semi-active muffler device of controlling the exhaust pipe’s low-frequency noise. Applied Acoustics, 116, 9–13. https://doi.org/10.1016/j.apacoust.2016.09.011.

Manente, V., Johansson, B., & Tunestal, P. (2009). Partially premixed combustion at high load using gasoline and ethanol, a comparison with diesel (No. 2009–01–0944). SAE Technical Paper. https://doi.org/10.4271/2009-01-0944.

Pal, P., Probst, D., Pei, Y., Zhang, Y., Traver, M., Cleary, D., & Som, S. (2017). Numerical investigation of a gasoline-like fuel in a heavy-duty compression ignition engine using global sensitivity analysis. SAE International Journal of Fuels and Lubricants, 10(1), 56–68. https://doi.org/10.4271/2017-01-0578.

Heywood, J. B. (1988). Internal combustion engine fundamentals. New York: McGraw-Hill.

Salazar, V. M., & Ghandhi, J. B. (2009). Ring pack crevice effects on the hydrocarbon emissions from an air-cooled utility engine. SAE International Journal of Engines, 1(1), 1319–1331.

Manente, V., Johansson, B., Tunestal, P., & Cannella, W. (2010). Effects of different type of gasoline fuels on heavy duty partially premixed combustion. SAE International Journal of Engines, 2(2), 71–88.

Manente, V. (2010). Gasoline partially premixed combustion-an advanced internal combustion engine concept aimed to high efficiency, low emissions and low acoustic noise in the whole load range (Doctoral dissertation, Lund University).

Won, H. W., Peters, N., Tait, N., & Kalghatgi, G. (2012). Sufficiently premixed compression ignition of a gasoline-like fuel using three different nozzles in a diesel engine. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 226(5), 698–708. https://doi.org/10.1177/0954407011423453.

Viollet, Y., Chang, J., & Kalghatgi, G. (2014). Compression ratio and derived cetane number effects on gasoline compression ignition engine running with naphtha fuels. SAE International Journal of Fuels and Lubricants, 7(2), 412–426. https://doi.org/10.4271/2014-01-1301.

Kim, K., Jung, Y., Kim, D., & Bae, C. (2016). Effect of injector configurations on combustion and emissions in a gasoline direct-injection compression ignition engine under low-load conditions. International Journal of Engine Research, 17(3), 316–330. https://doi.org/10.1177/1468087415573799.

Pei, Y., Pal, P., Zhang, Y., Traver, M., Cleary, D., Futterer, C., Brenner, M., Probst, D., & Som, S. (2019). CFD-guided combustion system optimization of a gasoline range fuel in a heavy-duty compression ignition engine using automatic piston geometry generation and a supercomputer. SAE International Journal of Advances and Current Practices in Mobility, 1(2019–01–0001), pp. 166–179. https://doi.org/10.4271/2019-01-0001.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Singh, H., Sonawane, U., Jena, A., Agarwal, A.K. (2021). Potential of Gasoline Compression Ignition Combustion for Heavy-Duty Applications in Internal Combustion Engines. In: Singh, A.P., Kumar, D., Agarwal, A.K. (eds) Alternative Fuels and Advanced Combustion Techniques as Sustainable Solutions for Internal Combustion Engines. Energy, Environment, and Sustainability. Springer, Singapore. https://doi.org/10.1007/978-981-16-1513-9_13

Download citation

DOI: https://doi.org/10.1007/978-981-16-1513-9_13

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-1512-2

Online ISBN: 978-981-16-1513-9

eBook Packages: EnergyEnergy (R0)