Abstract

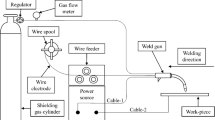

Continually increasing demands in pipeline welding concerning quality, frequent usage of superior, heat-sensitive, and corrosion-resistant materials alongside high assembly costs encourage the assessment of a welding process in detail. The only way to conquer such problems was the adaptation of technologically innovative welding methods that integrate the goodness of sophisticated power supply units and advanced software configuration. One such method is regulated metal deposition (RMDTM) welding. This work explores the influence of RMDTM welding variables and optimizes them for the best output responses. For that, voltage (V), current (A), and gas flow rate (GFR) were selected as welding variables, and their responses have been measured in terms of bead height (BH), bead width (BW), heat-affected zone (HAZ), and depth of penetration (DOP) by taking bead-on-plate trails on chrome moly steel plates. A novel optimization route based on the integrated concept of the TOPSIS-Taguchi approach has also been proposed, which delivers the optimal parametric setting as current = 100 A, voltage = 13 V, and gas flow rate = 21 L/min.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Dinbandhu, Prajapati, V., Vora, J.J., Das, S., Abhishek, K.: Experimental studies of Regulated Metal Deposition (RMDTM) on ASTM A387 (11) steel: study of parametric influence and welding performance optimization. J. Braz. Soc. Mech. Sci. Eng. 42, 78 (2020). https://doi.org/10.1007/s40430-019-2155-3

Bandhu, D., Kumar, R., Nishant, A., Thakur, A.: Characterization of friction stir welding for AA 2014-6061 and influence of aging on their mechanical behavior. In: 5th National Conference on Topical Transcend in Mechanical Technology SJBIT Bangalore (TTMT-17) International, pp. 98–102 (2017)

Das, S., Vora, J.J., Patel, V.: Regulated Metal Deposition (RMDTM) technique for welding applications: an advanced gas metal arc welding process. In: Advances in Welding Technologies for Process Development, pp. 23–32 (2019)

Bandhu, D., Jani, S., Thakur, A.: Characterization of frictional stir welding for two dissimilar materials and influence of ageing on their mechanical properties. Int. J. Res. Eng., IT Social Sci. 07, 21–25 (2017)

Cuhel, J.: Modified GMAW for Root Passes. TPJ-Tube Pipe J.-Fabricator, 1–4 (2008)

Roth, M.: Shinn Mechanical Uses PipeWorx Welding System to Increase Pipe Fabrication Quality and Productivity (2018)

Roth, M.: Graham Corporation Meets Reduced Rework Objectives With Help from Miller’s PipeWorxTM Welding Systems (2018)

Cuhel, J., Packard, K.: RMD ® Short-Circuit Metal Transfer, Pulsed MIG Processes with Metal-Cored Wires Improve Pipe Fabrication for Swartfager Welding, pp. 1–8 (2018)

Nascimento, L.A. do, Vilarinho, L.O.: Evaluation of GMAW Processes GMAW Controlled Short- Circuit Transfer (STT) applied To Mechanized Girth Welding. In: Congresso Nacional de Engenharia Mecânica Fortaleza/CE, pp. 1–16 (2016)

Sharma, P., Dwivedi, D.K.: Comparative study of activated flux-GTAW and multipass-GTAW dissimilar P92 steel-304H ASS joints. Mater. Manuf. Processes 34, 1195–1204 (2019). https://doi.org/10.1080/10426914.2019.1605175

Hilkes, J., Gross, V.: Welding CrMo steels for power generation and petrochemical applications—past, present and future-. Weld. World 53, 499–504 (2009)

Sumesh, A., Nair, B.B., Rameshkumar, K., Santhakumari, A., Raja, A., Mohandas, K.: Decision tree based weld defect classification using current and voltage signatures in GMAW process. In: Materials Today: Proceedings, pp. 8354–8363. Elsevier (2018). https://doi.org/10.1016/j.matpr.2017.11.528

Terner, M., Bayarsaikhan, T.-A., Hong, H.-U., Lee, J.-H.: Influence of gas metal arc welding parameters on the bead properties in automatic cladding. J. Weld. Joining 35, 16–25 (2017). https://doi.org/10.5781/jwj.2017.35.1.16

Prajapati, V., Dinbandhu, Vora, J.J., Das, S., Abhishek, K.: Study of parametric influence and welding performance optimization during regulated metal deposition (RMDTM) using grey integrated with fuzzy taguchi approach. J. Manuf. Processes 54, 286–300 (2020). https://doi.org/10.1016/j.jmapro.2020.03.017

Vommi, V.B.: Topsis with statistical distances: a new approach to MADM. Decis. Sci. Lett. 6, 49–66 (2017). https://doi.org/10.5267/j.dsl.2016.8.001

Panda, S.N., Bagal, D.K., Pattanaik, A. Kumar, Patnaik, D., Barua, A., Jeet, S., Parida, B., Naik, B.: Comparative evaluation for studying the parametric influences on quality of electrode using taguchi method coupled with MOORA, DFA, and TOPSIS method for electrochemical machining. In: Recent Advances in Mechanical Infrastructure, pp. 115–129 (2020). https://doi.org/10.1007/978-981-32-9971-9_13

Sonkar, V., Abhishek, K., Datta, S., Mahapatra, S.S.: Multi-objective optimization in drilling of GFRP composites: a degree of similarity approach. In: 3rd International Conference on Materials Processing and Characterisation (ICMPC 2014), pp. 538–543. Elsevier (2014). https://doi.org/10.1016/j.mspro.2014.07.068

Kamaraj, M., Santhanakrishnan, R., Muthu, E.: Investigation of surface roughness and MRR in drilling of Al2O3 particle and sisal fibre reinforced epoxy composites using TOPSIS based Taguchi method. In: IOP Conference Series: Materials Science and Engineering. Institute of Physics Publishing (2018). https://doi.org/10.1088/1757-899X/402/1/012095

Abhishek, K.: Experimental Investigations on Machining of CFRP Composites: Study of Parametric Influence and Machining Performance Optimization (2015). https://doi.org/10.1007/s11390-005-0552-9

Sun, C.C., Lin, G.T.R.: Using fuzzy TOPSIS method for evaluating the competitive advantages of shopping websites. Expert Syst. Appl. 36, 11764–11771 (2009). https://doi.org/10.1016/j.eswa.2009.04.017

Velasquez, M., Hester, P.T.: An Analysis of Multi-Criteria Decision Making Methods (2013)

Kumar Verma, R., Kumar, J., Kumar Kharwar, P., Abhishek, K.: TOPSIS based Taguchi approach for Multi-criteria optimization in quality and productivity characteristics

Vora, J.J., Abhishek, K., Ramkumar, P.: Different methodologies for the parametric optimization of welding processes. In: Advances in Welding Technologies for Process Development, pp. 55–75. CRC Press (2019). https://doi.org/10.1201/9781351234825-4

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Dinbandhu, Abhishek, K. (2021). Parametric Optimization and Evaluation of RMDTM Welding Performance for ASTM A387 Grade 11 Steel Plates Using TOPSIS-Taguchi Approach. In: Patnaik, A., Kozeschnik, E., Kukshal, V. (eds) Advances in Materials Processing and Manufacturing Applications. iCADMA 2020. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-0909-1_22

Download citation

DOI: https://doi.org/10.1007/978-981-16-0909-1_22

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-0908-4

Online ISBN: 978-981-16-0909-1

eBook Packages: EngineeringEngineering (R0)