Abstract

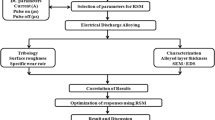

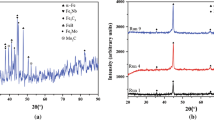

The present paper elaborates process for production of solid-lubricating coating over the mild steel by electrical discharge technique through green compact electrode made of MoS2 + Cu powder. Electrical discharge coating which is based on EDM principle and performed with the help of powder compact electrode formed via hot mounting press. The transportation of material occurred through electrical discharges which helps in melting and simultaneous deposition of powder. The loose bonding between particles facilitates the material deposition over the substrate. The effect of input parameters variation on the output parameters, such as, tool wear rate, mass deposition rate, and coating layer thickness is investigated by response surface methodology (RSM). The experiments results achieved from this work show that experimental values are in good agreement with the predictive results. The morphology study showed minimum amount of defects at the top coated surface. EDS study confirmed the successful deposition of principal elements presence in the coating.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Murray JW, Algodi SJ, Fay MW, Brown PD, Clare AT (2017) Formation mechanism of electrical discharge TiC-Fe composite coatings. J Mater Process Technol 243:143–151

Beri N, Maheshwari S, Sharma C, Kumar A (2010) Technological advancement in electrical discharge machining with powder metallurgy processed electrodes: a review. Mater Manuf Processes 25(10):1186–1197

Patowari PK, Saha P, Mishra PK (2010) Artificial neural network model in surface modification by EDM using tungsten–copper powder metallurgy sintered electrodes. Int J Adv Manuf Technol 51(5–8):627–638

Krishna ME, Patowari PK (2014) Parametric study of electric discharge coating using powder metallurgical green compact electrodes. Mater Manuf Processes 29:1131–1138

Goto A (2001) Development of electrical discharge coating method. In: 13th proceedings of the international symposium for electromaching

Zhen J, Cheng J, Zhu S, Hao J, Qiao Z, Yang J, Liu W (2017) High-temperature tribological behavior of a nickel alloy matrix solid-lubricating composite under vacuum. Tribol Int 110:52–56

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Tyagi, R., Kumar, S., Das, A.K., Mandal, A. (2022). Fabrication of Solid Lubricant Coating and Its Optimization Using Response Surface Methodology. In: Kumar, R., Chauhan, V.S., Talha, M., Pathak, H. (eds) Machines, Mechanism and Robotics. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-0550-5_12

Download citation

DOI: https://doi.org/10.1007/978-981-16-0550-5_12

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-0549-9

Online ISBN: 978-981-16-0550-5

eBook Packages: EngineeringEngineering (R0)