Abstract

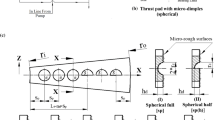

Performance behaviours of a sector-shaped hydrodynamic thrust bearing have been presented herein, incorporating the combined geometry of a pocket and a fish (Rohita Labeo) scale texture on the pad surface. The governing Reynolds equation incorporating the mass conservation algorithm is discretized employing FEM and then the solution of the sets of the equations by applying FBNS method. Based on the numerical investigation, it is found that the textured pad enhances the film load capacity and reduces the friction coefficient than the conventional pad case.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Abbreviations

- a :

-

Fish texture width (m)

- b :

-

Spacing of fish textures (m)

- h :

-

Film thickness (m)

- \(\overline{h}\) :

-

\(= h/h_{2}\)

- h 1 :

-

Inlet film thickness (m)

- h 2 :

-

Minimum (exit) film thickness (m)

- h d :

-

Pocket/Texture depth (m)

- \(\overline{h}_{T}\) :

-

\(= (h + h_{d} )/h_{2}\)

- M r :

-

\(= (2r_{z} + b)/(a + b)\)

- n :

-

Unit normal vector

- N :

-

Shape function

- N f :

-

\(= \theta_{f} /\theta_{c}\)

- N fp :

-

\(= (\theta_{f} - \theta_{p} )/\theta_{c}\)

- N r :

-

Total elements in radial direction

- N θ :

-

Total elements in sliding direction

- p :

-

Gauge pressure (N/m2)

- \(\overline{p}\) :

-

\(= ph_{2}^{2} /(\mu_{0}\Omega R_{1}^{2} )\)

- r :

-

Radial coordinate (m)

- \(\overline{r}\) :

-

\(= r/R_{1}\)

- r initial :

-

= (0.5 × ΔR − rz)

- r z :

-

Width of pocket in r direction (m)

- R 1 :

-

Inner radius of bearing (m)

- R 2 :

-

Bearing outer radius (m)

- ΔR (or B):

-

Bearing width (m)

- \(\theta_{f}\) :

-

Circumferential extents of pocket/texture

- \(\theta_{0}\) :

-

Pad angle (degree)

- \(\theta_{p}\) :

-

Circumferential extents of pocket in case of pocketed-fish textured pad

- \(\mu_{0}\) :

-

Viscosity 40 °C temperature (N-s/m2)

- Ω:

-

Speed (s−1)

- \(\phi\) :

-

Cavity or void fraction \((1 - \rho /\rho_{0} )\)

References

Gropper D, Wang L, Harvey TJ (2016) Hydrodynamic lubrication of textured surfaces: a review of modelling techniques and key findings. Tribol Int 94:509–529

Sudeep U, Tandon N, Pandey RK (2015) Performance of lubricated rolling/sliding concentrated contacts with surface textures: a review. J Tribol 137:031501

Rahmani F, Pandey RK, Dutt JK (2018) Performance studies of powder lubricated journal bearing having different pocket shapes at cylindrical bore surface. J Tribol 140:031704

Kharbanda JK, Pandey RK (2014) Application of tribology for enhancing the life of sugar mill roll bearing and journal. Int Sugar J 116:490–495

Gherca AR, Maspeyrot P, Hajjam M, Fatu A (2013) Influence of texture geometry on the hydrodynamic performances of parallel bearings. Tribol Trans 56:321–332

Aggarwal S, Pandey RK (2017) Frictional and load-carrying behaviours of micro-textured sector shape pad thrust bearing incorporating the cavitation and thermal effects. Lubr Sci 29:255–277

Aggarwal S, Pandey RK (2018) Performance investigation of micro-pocketed textured pad thrust bearing. Ind Lubr Tribol 70:1388–1395

Atwal JC, Pandey RK (2020) Performance analysis of thrust pad bearing using micro-rectangular pocket and bionic texture. Proc Instit Mech Eng Part J J Eng Tribol. https://doi.org/10.1177/1350650120940076

Atwal JC, Pandey RK (2020) Film thickness and friction investigations in a fluid film thrust bearing employing new conceived micro-texture on pads. J Tribol. https://doi.org/10.1115/1.4048500

Giacopini M, Fowell MT, Dini D, Strozzi A (2010) A mass-conserving complementarity formulation to study lubricant films in the presence of cavitation. J Tribol 132:041702

Woloszynski T, Podsiadlo P, Stachowiak GW (2015) Efficient solution to the cavitation problem in hydrodynamic lubrication. Tribol Lett 58:18

Acknowledgements and Declaration of Conflict of Interests

The authors would like to acknowledge the usage of IIT Delhi’s Baadal and HPC facilities. Moreover, the authors declare that there are no conflicts of interest in publishing this paper.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Atwal, J.C., Pandey, R.K. (2022). Synergistic Effect of Pocket and Bionic Texture on the Performance Behaviours of Thrust Pad Bearing. In: Kumar, R., Chauhan, V.S., Talha, M., Pathak, H. (eds) Machines, Mechanism and Robotics. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-0550-5_109

Download citation

DOI: https://doi.org/10.1007/978-981-16-0550-5_109

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-0549-9

Online ISBN: 978-981-16-0550-5

eBook Packages: EngineeringEngineering (R0)