Abstract

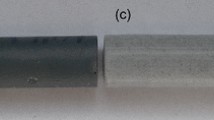

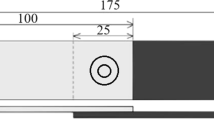

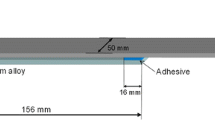

The aim of this paper is to assess the potential of accelerating the curing of epoxy adhesives by means of induction and ferromagnetic curie particles in the electronic and the automotive industries. Commercially available Araldite 2011 and Jowat 690 epoxy adhesives were considered, while Mn-Zn-Ferrite particles were considered for the modification of the adhesives. Induction experiments were performed at frequencies ranging from 188 to 262 kHz, and with particle weight content of 16.7 and 30%. The effects of the induction frequency and the particle content on the temperature of the adhesive were investigated. In addition, the effect of the particle content on the lap shear strength of bonded joints was also studied. Moreover, a comparison between the lap shear strength of inductively cured joints and reference oven cured joints was performed. Results showed that the temperature of the adhesive increased with increasing both the induction frequency and the particle content. However, the lap shear strength of joints with Araldite 2011 was reduced by 17% when increasing the particle content to 30%. No impact on the strength was observed in the case of the Jowat 690 at 16.7 and 30% particle contents. This suggests that increasing the induction frequency is more efficient in increasing the adhesive temperature without compromising the lap shear strength of the brittle adhesive. Furthermore, the inductively cured samples of the Araldite 2011 with 30% particles achieved a substantial 120% of the reference lap shear strength of oven cured samples in 8% of the curing time. For samples with Jowat 690 with 30% particles, the inductively cured samples achieved 43% of the reference lap shear strength of oven cured samples in 8% of the curing time. This shows a high potential of accelerating the curing time for industrial applications by induction and ferromagnetic curie particles, to reach either high strength as in case of Araldite 2011 or the handling strength as in case of Jowat 690.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Arnosky J (2001) Induction heating in the manufacture of electric motors. Proceedings: Electrical Insulation Conference and Electrical Manufacturing and Coil Winding Conference. (Cat. No.01CH37264) Cincinnati, OH, USA, 57–62. https://doi.org/10.1109/EEIC.2001.965589

Rudnev V, Loveless D, Cook RL (2018) Handbook of induction heating, 2nd edn. CRC Press

Bayerl T, Schledjewski R, Mitschang P (2012) Induction heating of thermoplastic materials by particulate heating promoters. Polym Polym Compos 20:333–342. https://doi.org/10.1177/096739111202000401

Vallée T, Adam M (2016) Inductively cured glued-in rods in timber using Curie particles. Int J Adhes Adhes 70:37–45. https://doi.org/10.1016/j.ijadhadh.2016.05.005

Severijns C, de Freitas ST, Poulis JA (2017) Susceptor-assisted induction curing behaviour of a two component epoxy paste adhesive for aerospace applications. Int J Adhes Adhes 75:155–164. https://doi.org/10.1016/j.ijadhadh.2017.03.005

Bardoliwalla DF (1997) Fast curing, low exotherm epoxy potting and encapsulating systems, Proceedings: Electrical Insulation Conference and Electrical Manufacturing and Coil Winding Conference, Rosemont, IL, USA, 245–247. https://doi.org/10.1109/EEIC.1997.651053

Dunn DJ (2004) Engineering and structural adhesives 15:1 iSmithers Rapra Publishing ISSN:0889-3144

R12K material characteristics datasheet, Hengdian Group DMEGC magnetic limited, China

ASTM D3163-01(2014) Standard test method for determining strength of adhesively bonded rigid plastic lap-shear joints in shear by tension loading, ASTM International, West Conshohocken, PA. https://www.astm.org

Acknowledgments

This research was conducted as a part of the FACIDO Project: Fast and Stable Adhesive Curing with Debonding Option. The project is partially funded by Flanders Make (the strategic research center for the manufacturing industry) and the Flemish Agency for Innovation and Entrepreneurship VLAIO through the CORNET framework (Grant number: HBC.2016.0668). The authors acknowledge the support of NiniX Technologies Belgium, and AGC-Glass Europe, Belgium.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Elmahdy, A. et al. (2021). Some Industrial Examples of Accelerated Curing Using Curie Particles. In: Silva, L., Adams, R., Sato, C., Dilger, K. (eds) Industrial Applications of Adhesives . Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-6767-4_2

Download citation

DOI: https://doi.org/10.1007/978-981-15-6767-4_2

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-6766-7

Online ISBN: 978-981-15-6767-4

eBook Packages: EngineeringEngineering (R0)