Abstract

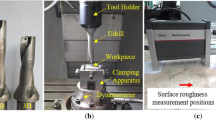

In this study, a drilling experiment was conducted on titanium alloy material by varying point angle of a carbide drill bits. The variables in the experiment were drilling speed, feed rate and point angle. A hybrid optimization technique, Taguchi-based fuzzy logic approach, is used to organize the drilling experiment. Totally, 27 experiments were conducted as per Taguchi L27 orthogonal array. The adequacy of experiment is further validated using normal probability values and residuals involved in the experiment. Moreover, the analysis of variance is used to identify the significant variable involved in the experiment. A fuzzy logic approach is used to validate the experiment by developing rules logically in a fuzzy inference system. Three membership functions for the inputs and nine membership functions for the outputs were considered in order to improve the accuracy of the predicted results. It is observed that feed rate and point angle are playing a vital role in the conducted experiment. And the overall effectiveness of the drilling experiment has improved by using Taguchi-based fuzzy approach.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Liu Z, Liu Y, Han X, Zheng W (2018) Study on super-long deep-hole drilling of titanium alloy. J Appl Biomater Funct Mater 16:150–156

Vijayan D, Abhishek P, Manoj Kumar YG, Balaji P, Siva kumar Reddy P (2018) Optimization of drilling parameters of carbon fiber composites using RSM based desirability function. In: IOP conference series: materials science and engineering, 390

Beranoagirre A, Urbikain G, Marticorena R, Bustillo A, López de Lacalle L (2019) Sensitivity analysis of tool wear in drilling of titanium aluminides. Metals 9

Beranoagirre A, Urbikain G, Calleja A, Lopez de Lacalle LN (2018) Drilling process in gamma-TiAl intermetallic alloys. Materials (Basel) 11

Samuel Raj D, Karunamoorthy L (2019) Performance of cryogenically treated WC drill using tool wear measurements on the cutting edge and hole surface topography when drilling CFRP. Int J Refract Metals Hard Mater 78:32–44

Kumar BS, Baskar N (2012) Integration of fuzzy logic with response surface methodology for thrust force and surface roughness modelling of drilling on titanium alloy. Int J Adv Manuf Technol 65:1501–1514

Vijayan D, Seshagiri Rao V (2016) Parametric optimization of friction stir welding process of age hardenable aluminum alloys−ANFIS modeling. J Central South Univ 23:1847–1857

Goyal R, Dubey AK (2016) Modeling and optimization of geometrical characteristics in laser trepan drilling of titanium alloy. J Mech Sci Technol 30:1281–1293

Vijayan D, Rao VS (2014) Friction stir welding of age-hardenable aluminum alloys: a parametric approach using RSM based GRA coupled with PCA. J Inst Eng (India) Series C 95:127–141

Vijayan D, Rao VS (2015) Parametric optimization of age hardenable aluminum alloys using TGRA coupled with PCA. Appl Mech Mater 813–814:613–619

Anand G, Alagumurthi N, Elansezhian R, Palanikumar K, Venkateshwaran N (2018) Investigation of drilling parameters on hybrid polymer composites using grey relational analysis, regression, fuzzy logic, and ANN models. J Brazilian Soc Mech Sci Eng 40

Abhishek K, Datta S, Mahapatra SS (2016) Multi-objective optimization in drilling of CFRP (polyester) composites: Application of a fuzzy embedded harmony search (HS) algorithm. Measurement 77:222–239

Rajmohan T, Palanikumar K, Prakash S (2013) Grey-fuzzy algorithm to optimise machining parameters in drilling of hybrid metal matrix composites. Compos B Eng 50:297–308

Vijayan D, Rao VS (2017) Optimization of friction stir welding process parameters using RSM based Grey—fuzzy approach. Saudi J Eng Technol 2:12–25

Vijayan D, Rao VS (2014) A Multi Response Optimization of Tool Pin Profile on the Tensile Behavior of Age-hardenable Aluminum Alloys during Friction Stir Welding. Res J Appl Sci Eng Technol 7:4503–4518

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Vijayan, D., Rajmohan, T., Raajesh Kanna, A. (2021). An Experimental Study on Drilling of Titanium Alloy Using Taguchi-Based Fuzzy Logic Approach. In: Rajmohan, T., Palanikumar, K., Davim, J.P. (eds) Advances in Materials and Manufacturing Engineering. Springer Proceedings in Materials, vol 7. Springer, Singapore. https://doi.org/10.1007/978-981-15-6267-9_55

Download citation

DOI: https://doi.org/10.1007/978-981-15-6267-9_55

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-6266-2

Online ISBN: 978-981-15-6267-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)