Abstract

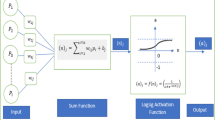

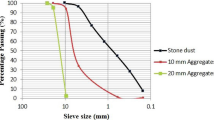

In the present study, we have used feed-forward neural network (FFNN) for the prediction of compressive and flexural strength of steel slag mixed concrete for pavements. The compressive and flexural strength of the specimens were examined experimentally for the specimens consisting of 0, 10, 15, 20 and 25% Argon Oxygen Decarburization (AOD) steel slag as a partial replacement of cement in M40 concrete mix. The curing of specimens was done for 3, 7, 28, 90, 180 and 365 days and thus accounting for the total of 90 observations. Both the output parameters were dependent upon 8 input parameters. To evaluate the performance of the FFNN model, we have used Mean Squared Error (MSE) and Mean Average Error (MAE) as the performance indicators.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Zhao H, Qi Y, Shi Y, Na X, Feng H (2013) Mechanism and prevention of disintegration of AOD stainless steel slag. J Iron Steel Res Int 20(4):26–30

Singh S, Ransinchung G, Debbarma S, Kumar P (2018) Utilization of reclaimed asphalt pavement aggregates containing waste from sugarcane mill for production of concrete mixes. J Clean Prod 174:42–52

Cao Z, Shen L, Zhao J, Liu L, Zhong S, Sun Y, Yang Y (2016) Toward a better practice for estimating the CO2 emission factors of cement production: an experience from China. J Clean Prod 139:527–539

Faisal M, Muhammad K et al (2016) Synthesis and characterization of geopolymer from bagasse bottom ash, waste of sugar industries and naturally available china clay. J Clean Prod 129:491–495

Rerkpiboon A, Tangchirapat W, Jaturapitakkul C (2015) Strength, chloride resistance, and expansion of concretes containing ground bagasse ash. Constr Build Mater 101:983–989

Oztas A, Pala M, Ozbay E, Kanca E, Caglar N, Bhatti MA (2006) Predicting the compressive strength and slump of high strength concrete using neural network. Constr Build Mater 20(9):769–775

Yeh I-C (1998) Modeling of strength of high-performance concrete using artificial neural networks. Cem Concr Res 28(12):1797–1808

Pham DT, Xing L (1995) Neural networks for identification, prediction and control. Springer Inc, New York

Kumar R, Srivastava S, Gupta J (2017) Modeling and adaptive control of nonlinear dynamical systems using radial basis function network. Soft Comput 21(15):4447–4463

Kumar R, Srivastava S, Gupta J (2017) Diagonal recurrent neural network based adaptive control of nonlinear dynamical systems using lyapunov stability criterion. ISA Trans 67:407–427

Chen S, Billings S, Grant P (1990) Non-linear system identification using neural networks. Int J Control 51(6):1191–1214

I. 44 (2008) Tentative guidelines for cement concrete mix design for pavements. Indian Road Congress, New Delhi

Indian Standard (2009) IS 10262, Concrete mix proportioning guidelines, Bureau of Indian Standards, New Delhi, India

I. 1989 (1989) Indian standard 43 grade ordinary Portland cement specification-code of practice

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Gupta, T., Sachdeva, S.N. (2021). A Novel Approach for Predicting the Compressive and Flexural Strength of Steel Slag Mixed Concrete Using Feed-Forward Neural Network. In: Pandey, V.C., Pandey, P.M., Garg, S.K. (eds) Advances in Electromechanical Technologies. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-5463-6_41

Download citation

DOI: https://doi.org/10.1007/978-981-15-5463-6_41

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-5462-9

Online ISBN: 978-981-15-5463-6

eBook Packages: EngineeringEngineering (R0)