Abstract

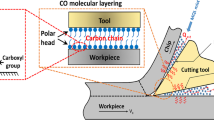

This work deals with the application of amylum additive-based cutting fluids while turning AISI 304 steel using carbide inserts. Amylum additive is dispersed in vegetable oil at varying percentages. Absorbance of the additive in pure bio-oil is examined using spectrophotometer, and thermal conductivity of these formulations is also obtained. Machining performance is assessed by comparing dry, synthetic cutting fluid, and pure oil for fixed cutting conditions. After basic machining, percentage of amylum additive is changed, and machining is done to examine the best concentration (0.3–0.9%) of additive in pure oil through minimal quantity lubrication technique. Machining performance is obtained by measuring cutting tool temperatures, surface roughness, and tool flank wear. It is inferred that, when compared to dry machining, synthetic fluid, and pure oil-assisted machining, amylum-assisted cutting fluids have resulted in improved machining performance owing to the reduction in cutting temperatures and better lubricity. Hence, it can be comprehended that amylum additive has the potential to be used as an additive in biodegradable oils in view of eco-friendly and user compatible machining operations.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Passman FJ, Roossmoore HW (2002) Re assessing the health risks associated with employee exposure of metal working fluid microbes. Lubr Eng 58(7):30–38

Bennett EO (1983) Water based cutting fluids and human health. Tribol Int 16(3):133–136

Korde VM, Phelps TJ, Bienkowski PR, White DC (1993) Biodegradation of chlorinated aliphatics and aromatic compounds in total-recycle expanded-bed reactors. Appl Biochem Biotechnol 45(46):731–740

Zeman A, Sprengel A, Niedermeier D, Spath M (1995) Biodegradable lubricants-studies on thermo oxidation of metal-working fluids by differential scanning calorimetry (DSC). Thermochim Acta 268:9–15

Kline & Company, Inc. (2006) Competitive intelligence for the global lubricants industry, 2004–2014. Kline & Company

Dilbag S, Rao PV (2007) Performance improvement of hard turning with solid lubricants. Int J Adv Manuf Technol 32:170–177

Suresh Kumar Reddy N, Rao PV (2005) Performance improvement of end milling using graphite as a solid lubricant. Mater Manuf Process 20:673–686

Krishna PV, Rao DN (2008) The influence of solid lubricant particle size on machining parameters in Turning. Int J Mach Tools Manuf 48(1):107–111

Susan W (2005) Vegetable oil-based metalworking fluids can provide better performance and environmental results than mineral oil-based fluids. Cutting Tool Mag 57(2):1–3

Belluco W, De Chiffre L (2002) Surface integrity and part accuracy in reaming and tapping stainless steel with new vegetable based cutting oils. Tribol Int 35:865–870

Alves SM, Oliveiria JFG (2005) Vegetable based cutting fluids: An environmental alternative to grinding process. In: Proceedings of the 15th CIRP international conference on life cycle engineering. Elsevier, pp 664–668

Ion IS, Camelia C, George C (2002) On the future of biodegradable vegetable lubricants used for industrial tribo systems. Ann Univ “Dunarea De Jos” Galati Fascicle 8:94–98

Wong KV, De Leon O (2010) Applications of nanofluids: current and future. In: Advances in Mechanical Engineering (Available online)

Das SK, Choi SU, Yu W, Pradeep T (2008) Nanofluids: science and technology. Wiley-Interscience, USA

Putra Nandy, Roetzel Wilfried, Das Sarit K (2003) Natural convection of nano-fluids. Heat Mass Transf 39:775–784

Xuan Y, Li Q (2000) Heat transfer enhancement of nanofluids. Int J Heat Fluid Flow 21:58–64

Shen B, Shih A, Tung SC (2008) Application of nanofluids in mql grinding. Tribol Lubr Technol 51:730–737

Diniz AE, Ferreira JR, Filho FT (2003) Influence of refrigeration/lubrication condition on SAE 52100 hardened steel turning at several cutting speeds. Int J Mach Tools Manuf 43:317–326

Abiodun MO, Adetan DA, Oladejo KA (2011) A Study of the performance of maize starch based cutting fluids in the turning of AISI 304 Stainless Steel. Int J Eng Res Afr 6:13–24

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Padmini, R., Vamsi Krishna, P., Jeevan Kumar, P. (2020). On the Role of Amylum Additive-Based Cutting Fluids in Machining—An Experimental Investigation. In: Voruganti, H., Kumar, K., Krishna, P., Jin, X. (eds) Advances in Applied Mechanical Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-1201-8_93

Download citation

DOI: https://doi.org/10.1007/978-981-15-1201-8_93

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-1200-1

Online ISBN: 978-981-15-1201-8

eBook Packages: EngineeringEngineering (R0)