Abstract

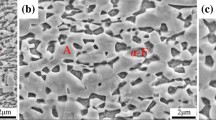

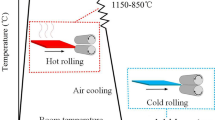

In the present study, reduced activation ferritic–martensitic steel subjected to thermomechanical treatment (TMT), in austenitic phase field and ferritic phase field, was evaluated for tensile properties (at temperatures 300–923 K) and compared with those under normalized and tempered (N+T) condition. The steel subjected to TMT in austenitic phase field consists of fully tempered martensitic structure and that subjected to TMT in ferritic phase field consists of the fully ferritic structure within prior austenite grain boundaries (PAGBs) after tempering treatment. In the case of TMT in austenitic phase field, allotriomorphic ferrite was also observed along the PAGBs of steel. The tempered martensite of TMT steels is decorated with the increased population of finer precipitates of M23C6 and MX-type compared to the N+T condition. The TMT process improved the strength properties of the steel over the N+T condition without compromising the ductility of the material. Interestingly, the steel subjected to TMT in austenitic phase field resulted in higher yield and ultimate tensile strengths compared to that in ferritic phase field. The improved tensile properties of the steel in TMT condition, over N+T condition, is thus attributed to the microstructural features such as the increase in dislocation density and the increased population of fine M23C6 and MX-type precipitates in TMT steel.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

R.L. Klueh, D.R. Harries, ASME, Philadelphia, 5 (2001)

A. Kohyama, Y. Kohno, K. Asakura, H. Kayano, J. Nucl. Mater. 212–215(1), 684–689 (1994)

N. Baluc, R. Schaublin, P. Spatig, M. Victoria, Nucl. Fusion 44, 56–61 (2004)

T. Jayakumar, M.D. Mathew, K. Laha, Procedia Eng. 55, 259–270 (2013)

K. Laha, S. Saroja, A. Moitra, R. Sandhya, M.D. Mathew, T. Jayakumar, J. Nucl. Mater. 439, 41–50 (2013)

J. Vanaja, K. Laha, M. Nandagopal, Shiju Sam, M.D. Mathew, T. Jayakuma, E. Rajendra Kumar, J. Nucl. Mater. 433, 412–418 (2013)

L. Tan, Y. Yang, J.T. Busby, J. Nucl. Mater. 442, S13–S17 (2013)

K.S. Chandravathi, C.S. Sasmal, K. Laha, P. Parameswaran, M. Nandagopal, V.D. Vijayanand, M.D. Mathew, T. Jayakumar, E. Rajendra Kumar, J. Nucl. Mater. 435 128–136 (2013)

R. Ravikirana, S. Mythili, S. Raju, T. Saroja, E. Jayakumar, Rajendrakumar. Mater. Char. 84, 196–204 (2013)

S. Raju, B. Jeya Ganesh, Arun Kumar, R. Mythili, S. Saroja, E. Mohandas, M. Vijayalakshmi, K.B.S. Rao, Baldev Raj, J. Nucl. Mater. 389, 385–393 (2009)

R.L. Klueh, N. Hashimoto, P.J. Maziasz, Sci. Mater. 53, 275–280 (2005)

K.S. Chandravathi, Kinkar Laha, C.S. Sasmal, P. Parameswaran, M. Nandagopal, H.M. Tailor, M.D. Mathew, T. Jayakumar, E. Rrajendra Kumar, Metall. Mater. Trans A 45A, 4280–4292 (2014)

J. Vanaja, Kinkar Laha, M.D. Mathew, Metall. Mater. Trans A 45A, 5076–5084 (2014)

J. Vanaja, K. Laha, Metall. Mater. Trans A 46(10), 4669–4679 (2015)

T. Sakthivel, P. Shruti, P. Parameswaran, G.V.S. Nageswara Rao, K. Laha, T. Srinivasa Rao, Trans. Indian Inst. Metall. 70(5), 1177–1182 (2017)

T. Furuhara, J. Yamaguchi N. Sugita, G. Miyamoto, T. Maki, ISIJ Int. 43, 1630–1639 (2003)

Matthias Nohrer, Walter Mayer, Sophie Primig, Sabine Zamberger, Ernst Kozeschnik, Harald Leitner, Metall. Mater. Trans. A 45A, 4210–4219 (2014)

P. Prakash, J. Vanaja, N. Srinivasan, P. Parameswaran, G.V.S. Nageswara Rao, K. Laha, Mater. Sci. Eng. A 724, 171–180 (2018

S.K. Sahay, H.K.D.H. Bhadeshia, R.W.K. Honeycombe, Mater. Sci. Eng., A 157, 101–105 (1992)

A. Benjamin, Shassere, Yukinori Yamamoto, Sudarsanam Suresh Babu, Metall. Mater. Trans. A 47A, 2190 (2016)

P. Fernandez, A.M. Lancha, J. Lapena, M. Hernandez-Mayoral, Fusion Eng. Des. 58–59, 787–792 (2001)

Prakash, J. Vanaja, K. Laha, G.V.S. Nageswara Rao, IOP conference series: materials science and engineering 338 (2018) 012027

V. Ganesan, K. Laha, P. Parameswaran, M. Nandagopal, M.D. Mathew, Mater. High Temp. 32, 4 (2015)

J. Christopher, B.K. Choudhary, E. Isaac Samuel, V.S. Srinivasan, M.D. Mathew, Mater. Sci. Eng. A 528 (2011) 6589–6595

G. Sainath, B.K. Choudhary, J. Christopher, E. Isaac Samuel, V.S. Srinivasan, M.D. Mathew, Int. J. Pres. Ves. Pip. 132–133 (2015) 1–9

Acknowledgements

The authors would like to acknowledge Dr. N. Srinivasan, Head, Metal Working Group, Defence Metallurgical Research Laboratory (DMRL), Kanchanbagh, Hyderabad for providing hot-rolling facilities.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Prakash, P., Vanaja, J., Prasad Reddy, G.V., Laha, K., Nageswara Rao, G.V.S. (2020). Influence of Thermomechanical Treatment in Austenitic and Ferritic Fields on Tensile Properties of Reduced Activation Ferritic–Martensitic Steel. In: Prakash, R., Suresh Kumar, R., Nagesha, A., Sasikala, G., Bhaduri, A. (eds) Structural Integrity Assessment. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-13-8767-8_9

Download citation

DOI: https://doi.org/10.1007/978-981-13-8767-8_9

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-8766-1

Online ISBN: 978-981-13-8767-8

eBook Packages: EngineeringEngineering (R0)