Abstract

Composite materials have brought new development and sizing possibilities for structural components in transportation systems. Their high specific material properties are enabling weight reduction while increasing structural performance. On the downside, composite materials are generally related to high material and manufacturing costs and increased characterization efforts. Through the braiding technique, profiled structures can be manufactured in a highly automated and reproducible process. Moreover, braided composites can absorb more energy compared to their unidirectional or woven counterparts ( Falzon P. J., Herszberg I., Bannister M. K., Leong K. H.: Compression and Compression-after-impact Properties of 2-D Braided Carbon/Epoxy Composites. Proceedings of the First Australasian Congress on Applied Mechanics: ACAM-96, pp. 297 (1996).).

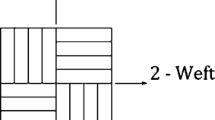

In this paper, we describe the development and validation of a simulation framework as sustainable alternative to material- and cost-intensive experimental testing. Our work aims at considering the influence of manufacturing effects and textile architecture on the material properties and therefore at increasing the reliability of structure sizing. As validation basis, flat specimens of biaxial and triaxial braided composites are first manufactured and tested under quasi-static loading. We then develop a digital twin of the braiding process and its material characterisation. Within this framework, the braid’s textile architecture is predicted with multiple finite-element simulations at the mesoscopic scale.

The numerical predictions show the strong influence of braiding angle and braiding core diameter on the textile architecture and consequently on the material properties. More particularly, crucial effects with negative impact on the mechanical properties (presence of gaps or yarn locking) are highlighted. On a pure numerical basis, we finally calculate the process window for braided structures, which links the process parameters to the resulting material properties. The present approach is a crucial step toward the reduction of experimental investigations in early development.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Falzon, P. J., Herszberg, I., Bannister, M. K., Leong, K. H.: Compression and Compression-after-impact Properties of 2-D Braided Carbon/Epoxy Composites. Proceedings of the First Australasian Congress on Applied Mechanics: ACAM-96, p. 297 (1996)

Dittmann, J., Middendorf, P., et al.: Der digitale Prototyp - Ganzheitlicher digitaler Prototyp im Leichtbau für die Großserienproduktion. ARENA2036 Reihe-DigitPro, Springer-Vieweg (2019)

Raichle, A., Ritter, F., Vinot, M., Dittmann, J. et al.: Weiterentwicklung des Digitalen Prototyps zum Digitalen Fingerabdruck, ATZ-Magazin 03/2019, Springer-Vieweg (2019)

Blonk, H., Kool, A., Luske, B., Ponsioen, T., Scholten, J.: Methodology for assessing carbon footprints of horticultural products. Blonk Milieu Advies, S. 36–40 (2010)

Böhler, P.: Einzelfadenbasierte Modellierung von textilen Preform-Prozessen. Dissertation Universität Stuttgart (2019)

Czichos, R., Bareiro, O., Pickett, A. K., Middendorf, P., Gries, T.: Experimental and numerical studies of process variabilities in biaxial carbon fiber braids. International Journal of Material Forming (2020)

DYNAmore GmbH; Envyo® User’s Manual-DRAFT, Germany (2020)

Whitcomb, J.D., Chapman, C.D., Tang, X.: Derivation of Boundary Conditions for Micromechanics Analyses of Plain and Satin Weave Composites. J. Compos. Mater. 34, 724–747 (2000)

Wehrkamp-Richter, T., Pinho, S.T., Hinterhölzl, R.: Failure behaviour of triaxial braided composites, 17th European Conference on Composite Materials (2016)

Kier, Z.T., Salvi, A., Theis, G., Waas, AM., Shahwan, K.: Estimating mechanical properties of 2D triaxially braided textile composites based on microstructure properties, Composites: Part B 68, 288–299 (2014)

Lin, H., Brown, L.P., Long, A.C.: Modelling and Simulating Textile Structures using TexGen. Adv. Tex. Eng. 331, 44–47 (2011)

Pinho, S., Iannucci, L., Robinson, P.: Physically based failure models and criteria for laminated fibre-reinforced composites with emphasis on fibre kinking. Part II: FE implementation, Composites Part A: Applied Science and Manufacturing 37, 766–777 (2005)

Kolling S., Haufe A., Feucht M., Du Bois P.A.: SAMP-1: A Semi-Analytical Model for the Simulation of Polymers, 4. LS-DYNA Anwenderforum (2005)

Pinho, S., Robinson, P., Iannucci, L.: Fracture toughness of the tensile and compressive fibre failure modes in laminated composites. Compos. Sci. Technol. 66, 2069–2079 (2006)

Birkefeld, K.: Virtuelle Optimierung von Geflecht-Preforms unter Berücksichtigung von Fertigungsaspekten. Universität Stuttgart, Institut für Flugzeugsbau (2013)

Acknowledgement

The authors wish to acknowledge the funding provided by the Federal Ministry of Education and Research Germany within the Research campus ARENA2036—DigitPro and Digitaler Fingerabdruck.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer-Verlag GmbH, DE, part of Springer Nature

About this paper

Cite this paper

Dittmann, J., Vinot, M., Middendorf, P., Toso, N., Voggenreiter, H. (2021). Simulation Supported Manufacturing of Profiled Composite Parts Using the Braiding Technique. In: Weißgraeber, P., Heieck, F., Ackermann, C. (eds) Advances in Automotive Production Technology – Theory and Application. ARENA2036. Springer Vieweg, Berlin, Heidelberg. https://doi.org/10.1007/978-3-662-62962-8_41

Download citation

DOI: https://doi.org/10.1007/978-3-662-62962-8_41

Published:

Publisher Name: Springer Vieweg, Berlin, Heidelberg

Print ISBN: 978-3-662-62961-1

Online ISBN: 978-3-662-62962-8

eBook Packages: EngineeringEngineering (R0)