Abstract

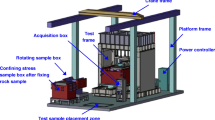

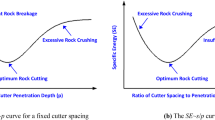

It is notoriously known there are lots of factors influence cutter efficiency and tool life for boring operations. The key problem is how much each influenced and where is the best balance point. This paper uses the orthogonal test method to simulate and verify the influence by the two most important cutting parameters, like cutting speed, cutting penetration (which is the same as cutting depth as in the mechanical machine). First, we used the optimized model and designed a new test mechanism. In the simulation part, we use Rock Failure Process Analysis simulates the rock fragments and the changes of stress field. With these new numerical algorithms, we can simulate the mass and cutting forces in the boring, and we finally find each balance point in the real boring in different cutting parameters. And we also updated a new liner cutting test experimental mechanism, which can simulate the real boring operations in the lab when we set different cutting parameters. We use the simulation and test method to verify our predicting result. We show that the best disc cutter shape is 10 mm flat cutter ring and the best cutting space in our project is 76 mm for 17 inch cutter ring in our cutting test. However, since we understand the complex of different factors we can bound the balance point to those values in certain boring condition.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Gertsch R, Gertsch L, Rostami J (2007) Disc cutting tests in colorado red granite: implications for TBM performance prediction. Int J Rock Mech Min Sci 44:238–246

Rostami J, Ozdemir L (1993) A new model for performance prediction of hardrock TBMs. In: Bowerman LD, Monsees JE (eds) Proceedings of rapid excavation and tunneling conference. AIME, Boston, MA, pp 793–809

Rostami J, Ozdemir L, Nilson B (1996) Comparison between CSM and NTH hard rock TBM performance prediction models. ISDT, Las Vegas

Nilsen B, Ozdemir L (1993) Hard rock tunnel boring prediction and field performance. In: Proceedings of rapid excavation and tunneling conference(RETC), Boston, USA, pp 833–852

Okan Su, NuriAliAkcin (2011) Numerical simulation of rock cutting using the discrete element method. Int J Rock Mech Min Sci 48:434–442

Gong QM, Jiao YY, Zhao J (2006) Numerical modelling of the effects of joint spacing on rock fragmentation by TBM cutters. Tunn Undergr Space Technol 21:46–55

Liua HY, Koua SQ, Lindqvist P-A, Tang CA (2002) Numerical simulation of the rock fragmentation process induced by indenters. Int J Rock Mech Min Sci 39:491–505

Ozdemir L, Nilsen B (1993) Hard rock tunnel boring prediction and field performance. In: Rapid excavation and tunneling conference (RETC) proceedings, Chap. 52, Boston, USA

Rostami J, Ozdemir L, Nilson B (1996) Comparison between CSM and NTH hard rock TBM performance prediction models. ISDT, Las Vegas

Lindqvist PA (1982) Rock fragmentation by inde, ltation and disc cutting, Doctoral Thesis. University of Lul&i, Sweden

Rostami J (1997) Development of a force estimation model for rock fragmentation with disc cutters through theoretical modeling and physical measurement of the crushed zone pressure, PhD thesis. Department of Mining Engineering, Colorado School of Mines

Alehossein H, Boland JN, et al (1995) Prediction of rock failure in rock indentation by a rock cutter. HDRK-CMTE report

TeAlehossein H, Hood M (1996) State-of-the-art review of rock models for disk roller-cutters. In: Aubertin M, Hassani F, Mitri H (eds) Second NARMS, rock mechanics tools and techniques. Balkema, Montreal, pp 693–700

Nilsen B, Ozdemir L (1993) Hard rock tunnel boring prediction and field performance. In: Proceedings of rapid excavation and tunneling conference (RETC), Boston, USA, pp 833–852

Rostami J, Ozdemir L (1993) A new model for performance prediction of hardrock TBMs. In: Bowerman LD, Monsees JE, (eds) Proceedings of rapid excavation and tunneling conference. AIME, Boston, MA, pp 793–809

Acknowledgments

This work was supported by grant No. 2010CB736000 from the national high technology research and development program of 973 Plan, the project name is Key research of tunnel boring machine and large grinding equipment. And thanks RFPA company support the software in simulation.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Wang, Z., Wang, W.S., Wang, J., Liu, C. (2014). Predicting and Verifying Forces by Using Different Cutters and Spaces. In: Wen, Z., Li, T. (eds) Practical Applications of Intelligent Systems. Advances in Intelligent Systems and Computing, vol 279. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-54927-4_17

Download citation

DOI: https://doi.org/10.1007/978-3-642-54927-4_17

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-54926-7

Online ISBN: 978-3-642-54927-4

eBook Packages: EngineeringEngineering (R0)