Abstract

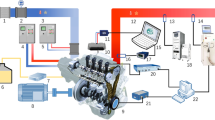

The combination of turbocharging and direct injection offers a significant potential for SI engines to improve fuel consumption, specific power output, raw emissions and transient behavior. To realize the full benefit of this combination Ricardo uses spray guided lean stratified operation with multiple injections. The Ricardo T-SGDI concept has already been presented at various international conferences and is constantly being developed using modern optimization techniques. This paper shows the latest results of the T-SGDI engine with a maximum brake thermal efficiency about 41 % and a BSFC of about 278 g/kWh at 2000 rpm and 2 bar BMEP. Additionally, the stabilization of combustion through the multiple injections allows EGR rates of up to 35 % in order to reduce NOx raw emissions. Further, this engine achieves 30 bar BMEP and 100 kW/l. These outstanding values are possible by combining different mechanisms such as charging, multiple injection, high Exhaust Gas Recirculation (EGR) rates plus the appropriate charge motion and combustion chamber design. At low loads, the multiple injections ensure stable combustion, even with residual gas fractions of up to 35 %. At medium loads the Ricardo Multiple Injection Variable Injection Separation (MIVIS) Strategy, through the distribution of the injection processes during the intake and compression strokes, in combination with boosting means that the lean operating range can be up extended to BMEP of 15 bar. At WOT, injection during both the induction and compression strokes leads to higher knock mitigation and, above 30 bar BMEP, to 50 % MFB at the thermodynamic optimum. The Ricardo T-SGDI concept thus achieves the efficiency of modern direct injection diesel engines whilst retaining the positive characteristics of a gasoline engine, such as a wide engine speed range and spontaneous power response.

F2012-A01-041

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Abbreviations

- °CA:

-

Degree Crank Angle

- AFR:

-

Air to Fuel Ratio

- aIgn:

-

Angle of Ignition

- ATDC:

-

After Top Dead Centre

- BTDC:

-

Before Top Dead Centre

- BMEP:

-

Brake Mean Effective Pressure

- BTE:

-

Brake Thermal Efficiency

- CAFE:

-

Corporate Average Fuel Economy

- CoV:

-

Coefficient of Variation

- DoE:

-

Design of Experiments

- EGR:

-

Exhaust Gas Recirculation

- HC:

-

Hydro Carbon

- IMEP:

-

Indicated Mean Effective Pressure

- MBT:

-

Minimum Spark Advance for Best Torque

- MFB:

-

Mass Fraction Burned

- NOx:

-

Nitric Oxides

- OEM:

-

Original Equipment Manufacturer

- PFI:

-

Port Fuel Injection

- SGDI:

-

Spray Guided Gasoline Direct Injection

- SPM:

-

Stochastic Process Model

- VVT:

-

Variable Valve Timing

References

Lückert P, Waltner A, Rau E, Vent G, Schaupp U (2006) Der neue V6-Ottomotor mit Direkteinspritzung von Mercedes-Benz, MTZ, pp 830–840

Schwarz Ch, Schünemann E, Durst B, Fischer J, Witt A (2006) Potentials of the spray-guided BMW DI combustion system. SAE Paper 2006-01-1265

Spicher U, Kubach H, Häntsche JP (2006) Die strahlgeführte Direkteinspritzung als Zukunftskonzept für Ottomotoren. MTZ-Konferenz Motor, Stuttgart

Reissing J (1999) Spektroskopische Untersuchungen an einem Ottomotr mit Benzin-Direkteinspritzung. Dissertation, Universität Karlsruhe (TH)

Kneifel A, Heidenreich Th, Velji A, Spicher U (2007) Experimentelle und numerische Untersuchungen an einem Ottomotor mit strahlgeführter Direkteinspritzung zur Erweiterung des Schichtladekennfeldes durch Aufladung, Berichte zur Energie- und Verfahrenstechnik, Schriftenreihe Heft 7.1, Haus der Technik

Sarikoc F, Kettner M, Velji A, Spicher U, Krause A, Elsässer A (2006) Potential of reducing the NOx emissions in a spray guided DI gasoline engine by stratified exhaust gas recirculation (EGR). SAE Paper 2006-01-1261

Basshuysen R (2008) Ottomotor mit Direkteinspritzung, Chapter 3, 2. Auflage. Vieweg + Teubner, Wiesbaden

Bäcker H, Tichy M, Lohfink C (2006) Einspritzstrategien für direkteinspritzende Benzinmotoren, Direkteinspritzung im Ottomotor

Acknowledgments

The authors would like to thank all the team members who have contributed to the work reported here and the directors of Ricardo for permission to publish this paper.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

King, J., Böcker, O. (2013). Multiple Injection and Boosting Benefits for Improved Fuel Consumption on a Spray Guided Direct Injection Gasoline Engine. In: Proceedings of the FISITA 2012 World Automotive Congress. Lecture Notes in Electrical Engineering, vol 189. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-33841-0_18

Download citation

DOI: https://doi.org/10.1007/978-3-642-33841-0_18

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-33840-3

Online ISBN: 978-3-642-33841-0

eBook Packages: EngineeringEngineering (R0)