Abstract

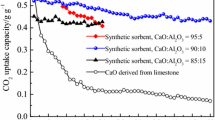

One of the post-combustion CO2 capture technologies that have sufficiently been proved to be the best candidates for practical large scale post-combustion application is the calcium looping cycle. However, the CO2 capture capacity of a calcium-based sorbent derived from natural limestone decays through long-term cyclic utilization; thus, the development of novel sorbents to achieve a high CO2 capture capacity is an critical challenge for the calcium looping cycle technology. In this paper, we report the preparation and character of a new calcium-based sorbent produced via the combustion of a dry gel. The results show that the novel calcium-based sorbent has a much higher residual carbonation conversion as well as a better performance of anti-sintering when compared with the calcium-based sorbent derived from commercial micrometer grade CaCO3 and nanometer grade CaCO3. It is reasonable to propose that the different final carbonation performances are induced by their different pore structures and BET surface areas rather than by different particle sizes. Compared with the commercial nano CaO, the morphology of the new sorbent shows a more rough porous appearance with hollow nanostructure. During carbonation, CO2 diffused more easily through the hollow structure than through a solid structure to reach the unreacted CaO. Besides, there is less chance for the hollow nanostructured particles to be merged together during the high temperature reactions.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Blamey J, Anthony EJ, Wang J, Fennell PS. The calcium looping cycle for large-scale CO2 capture. Prog Energy Combust Sci. 2010;36(2):260–79.

Fan LS, Li FX. Chemical looping technology and its fossil energy conversion applications. Ind Eng Chem Res. 2010;49(21):10200–11.

Herzog H. What future for carbon capture and sequestration. Environ Sci Technol. 2001;35(7):148A–53.

Shimizu T, Hirama T, Hosoda H, Kitano K, Inagaki M, Tejima K. A twin fluid-bed reactor for removal of CO2 from combustion processes. Chem Eng Res Des. 1999;77(A1):62–8.

Feng B, An H, Tan E. Screening of CO2 adsorbing materials for zero emission power generation systems. Energy Fuel. 2007;21(2):426–34.

Romeo LM, Abanades JC, Escosa JM, Pano J, Gimenez A, Sanchez-Biezma A, Ballesteros JC. Oxyfuel carbonation/calcination cycle for low cost CO2 capture in existing power plants. Energy Convers Manage. 2008;49(10):2809–14.

Romeo LM, Lara Y, Lisbona P, Martinez A. Economical assessment of competitive enhanced limestones for CO2 capture cycles in power plants. Fuel Process Technol. 2009;90(6):803–11.

Lisbona P, Martinez A, Lara Y, Romeo LM. Integration of carbonate CO2 capture cycle and coal-fired power plants. A comparative study for different sorbents. Energy Fuel. 2010;24(1):728–36.

Albrecht KO, Satrio JA, Shanks BH, Wheelock TD. Application of a combined catalyst and sorbent for steam reforming of methane. Ind Eng Chem Res. 2010;49(9):4091–8.

Liu WQ, Low NWL, Feng B, Wang GX, da Costa JCD. Calcium precursors for the production of CaO sorbents for multicycle CO2 capture. Environ Sci Technol. 2010;44(2):841–7.

Florin NH, Harris AT. Review: enhanced hydrogen production from biomass with in situ carbon dioxide capture using calcium oxide sorbents. Chem Eng Sci. 2008;63(2):287–316.

Ramkumar S, Fan LS. Calcium looping process (CLP) for enhanced noncatalytic hydrogen production with integrated carbon dioxide capture. Energy Fuel. 2010;24(8):4408–18.

Aihara M, Nagai T, Matsushita J, Negishi Y, Ohya H. Development of porous solid reactant for thermal-energy storage and temperature upgrade using carbonation/decarbonation reaction. Appl Energy. 2001;69(3):225–38.

Manovic V, Anthony EJ. CO2 carrying behavior of calcium aluminate pellets under high-temperature/high-CO2 concentration calcination conditions. Ind Eng Chem Res. 2010;49(15):6916–22.

Li YJ, Zhao CS, Qu CR, Duan LB, Li QZ, Liang C. CO2 capture using CaO modified with ethanol/water solution during cyclic calcination/carbonation. Chem Eng Technol. 2008;31(2):237–44.

Luo C, Zheng Y, Ding N, Wu QL, Bian G, Zheng CG. Development and performance of CaO/La2O3 sorbents during calcium looping cycles for CO2 capture. Ind Eng Chem Res. 2010;49(22):11778–84.

Li ZS, Cai NS, Croiset E. Process analysis of CO2 capture from flue gas using carbonation/calcination cycles. AIChE J. 2008;54(7):1912–25.

Lu H, Khan A, Pratsinis SE, Smirniotis PG. Flame-made durable doped-CaO nanosorbents for CO2 capture. Energy Fuel. 2009;23(1):1093–100.

Alvarez D, Abanades JC. Determination of the critical product layer thickness in the reaction of CaO with CO2. Ind Eng Chem Res. 2005;44(15):5608–15.

Sun P, Lim J, Grace JR. Cyclic CO2 capture by limestone-derived sorbent during prolonged calcinations/carbonation cycling. AIChE J. 2008;54(6):1668–77.

Crasa GS, Abanades JC. CO2 capture capacity of CaO in long series of carbonation/calcination cycles. Ind Eng Chem Res. 2006;45(26):8846–51.

Acknowledgments

The authors acknowledge the financial supports of National Basic Research Program of China (No.2011CB707301), and the National Natural Science Foundation of China (No.50936001, 51021065). The authors are also grateful to Analytical and Testing Center of Huazhong University of Science and Technology for FSEM measurements.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer-Verlag Berlin Heidelberg & Tsinghua University Press

About this paper

Cite this paper

Luo, C., Zheng, Y., Ding, N., Zheng, Cg. (2013). Calcium Looping Technology Using Improved Stability Nanostructured Sorbent for Cyclic CO2 Capture. In: Qi, H., Zhao, B. (eds) Cleaner Combustion and Sustainable World. ISCC 2011. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-30445-3_154

Download citation

DOI: https://doi.org/10.1007/978-3-642-30445-3_154

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-30444-6

Online ISBN: 978-3-642-30445-3

eBook Packages: EnergyEnergy (R0)