Abstract

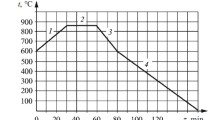

The authors of the article present and prove the possibility of reducing the economic and environmental indicators in the processes of mineral fertilizers granulation by means of recycling and using organic agricultural waste. It is shown that such waste products are in the form of very moist suspensions, therefore, in order to minimize energy consumption for their processing, the optimal technology for granular product preparation is granulation in the fluidized bed apparatus. For this purpose there has been conducted the physical modelling of the granule formation process and one found out the conditions of suspended layer formation, which determine the nature of the dispersed suspension and dispersed solid phase interaction. One has experimentally established the temperature regimes of organic suspensions granulation and determined the operating parameters of the process. The kinetics of coarsening of granules was studied depending on the temperature of dehydration of organic suspensions. Analytical dependencies that are determined by the heat transfer coefficient are obtained to determine the time and temperature of granule heating.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Jarchow, M.E., Liebman, M.: Nitrogen fertilization increases diversity and productivity of prairie communities used for bioenergy. GCB Bioenergy 5(3), 281–289 (2012)

Goertz, H.M., Timmons, R.J., Johnson, W.R.: Precoated controlled release fertilizers and processes for their preparation. Patent No. 6039781 A, United States (2008)

Gupta, S.K., Singhvi, I.J., Shirsat, M.K., Karwani, G., Agarwal, A.: Microencapsulation techniques and its application in pharmaceutical. Asian J. Pharm. Sci. Clin. Res. 1(3), 67–77 (2011)

Politi, G., Heilakka, E.: Granules, tablets and granulation. Patent No. 20080111269, United States (2008)

Jordon, S., Jordan, J.: Controlled release fertilizer and system and method. Patent No. 7674313 B2, United States (2010)

Mente, D.: Encapsulated Particle. Patent No. 2396237, Russia, Ch. (2010)

Izquierdo-Barrientos, M.A., Sobrino, C., Almendros-Ibàñez, J.A.: Thermal energy storage in a fluidized bed of PCM. Chem. Eng. J. 230, 573–583 (2013)

Niedziela, D., Schmidt, S., Steiner, K., Zausch, J., Zemerli, C.: Continuum numerical simulation of multiphase granular suspension flow in the context of applications for the mechanical processing industry. Int. J. Miner. Process. 136, 50–55 (2015)

Ostroha, R.O., Yukhymenko, M.P., Mikhajlovskiy, Y.E., Litvinenko, A.V.: Technology of producing granular fertilizers on the organic basis. East. Eur. J. Enterp. Technol. Ser. Technol. Organ. Inorgan. Subst. 1/6(79), 19–26 (2016)

Nawozy wolnodzialajace: Oznaczanie uwalniania skladnikow odzywczych. Metoda dla nawozow otoczkowanych. Norma europejska EN 13266:2001, 12, Poland (2003)

Acknowledgement

This research was conducted under the project «Improving the Efficiency of Granulators and Dryers with Active Hydrodynamic Regimes for Obtaining, Modification and Encapsulation of Fertilizers» (State Reg. No. 0116U006812).

Also this research was partially supported by research grant from the Slovak Grant Agency VEGA Project 1/0731/16 «Development of Modern Numerical and Experimental Methods of Mechanical System Analysis».

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer International Publishing AG, part of Springer Nature

About this paper

Cite this paper

Ostroha, R., Yukhymenko, M., Lytvynenko, A., Bocko, J., Pavlenko, I. (2019). Granulation Process of the Organic Suspension: Fluidized Bed Temperature Influence on the Kinetics of the Granule Formation. In: Ivanov, V., et al. Advances in Design, Simulation and Manufacturing. DSMIE 2019. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-319-93587-4_48

Download citation

DOI: https://doi.org/10.1007/978-3-319-93587-4_48

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-93586-7

Online ISBN: 978-3-319-93587-4

eBook Packages: EngineeringEngineering (R0)