Abstract

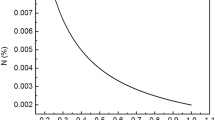

The coarse TiN inclusions can act as potential fracture initiation sites and deteriorate the impact toughness of steels. The experimental observation results indicated that CaS and TiN inclusions precipitated in solidification mushy zone. Meanwhile, it was found that CaS inclusions could act effectively a heterogeneous nucleation substrate for the precipitation of TiN inclusions, and the size of TiN inclusions with CaS core was obviously larger than those TiN inclusions without CaS core. Additionally, the thermodynamic calculation result showed that TiN inclusions began to precipitate at the end of solidification from the dendrites front; moreover, the preexisted CaS inclusions promoted the formation of TiN inclusions. Decreasing sulfur and nitrogen content could significantly reduce precipitation temperature and growth time of CaS and TiN inclusions in mushy zone. Furthermore, TiN inclusions could be prevented from precipitation at the surface of CaS inclusions when the S content of molten steel was below 0.0008 wt%.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Chen J (2013) Influence of deformation temperature on γ-α phase transformation in Nb–Ti microalloyed steel during continuous cooling. ISIJ Int 53(6):1070–1075

Ralph BHKDK, Bhadeshia RWK (2006) Honeycombe steels (Microstructure and properties), 3rd edn. Elsevier, Amsterdam. 978-0-750-68084-4344; Mater Charact 59(3):348

Guo YT, He SP, Chen GJ, Wang Q (2016) Thermodynamics of complex sulfide inclusion formation in Ca-Treated Al-Killed Structural Steel. Metallurg Mater Trans B 47(4):2549–2557

Liu Y, Zhang L, Duan H, Zhang Y, Luo Y, Conejo AN (2016) extraction, thermodynamic analysis, and precipitation mechanism of MnS-TiN complex inclusions in low-sulfur steels. Metallurg Mater Trans A 47(6):3015–3025

Holappa L, Hämäläinen M, Liukkonen M, Lind M (2013) Thermodynamic examination of inclusion modification and precipitation from calcium treatment to solidified steel. Ironmaking Steelmaking 30(2):111–115

Xu G, Jiang Z, Li Y (2016) Formation mechanism of CaS-bearing inclusions and the rolling deformation in al-killed, low-alloy steel with Ca treatment. Metall Mater Trans B 47(4):2411–2420

Prikryl M, Kroupa A, Weatherly GC, Subramanian SV (1996) Precipitation behavior in a medium carbon, ti-v-n microalloyed steel. Metall Mater Trans A 27(5):1149–1165

Yan W, Shan YY, Yang K (2006) Effect of TiN inclusions on the impact toughness of low-carbon microalloyed steels. Metall Mater Trans A 37(7):2147–2158

Yan W, Shan YY, Yang K (2007) Influence of TiN inclusions on the cleavage fracture behavior of low-carbon microalloyed steels. Metall Mater Trans A 38(6):1211–1222

Strangwood M, Davis CL (2012) Effect of TiN particles and grain size on the charpy impact transition temperature in steels. J Mater Sci Technol 28(10):878–888

Ma F, Wen G, Tang P, Yu X, Li J, Xu G et al (2010) In situ observation and investigation of effect of cooling rate on slab surface microstructure evolution in microalloyed steel. Ironmaking Steelmaking 37(3):211–218

Dou K, Meng L, Liu Q, Liu B, Huang Y (2016) Influence of cooling rate on secondary phase precipitation and proeutectoid phase transformation of micro-alloyed steel containing vanadium. Met Mater Int 22(3):349

Mintz B (2008) Understanding the low temperature end of the hot ductility trough in steels. Mater Sci Technol 24(1):112–120

Carpenter KR, Dippenaar R, Killmore C (2009) Hot ductility of Nb-and Ti-bearing microalloyed steels and the influence of thermal history. Metall Mater Trans A 40(3):573–580

Zhang LP, Davis CL, Strangwood M (2001) Dependency of fracture toughness on the inhomogeneity of coarse TiN particle distribution in a low alloy steel. Metall Mater Trans A 32(5):1147–1155

Shibata H, Arai Y, Suzuki M, Emi T (2000) Kinetics of peritectic reaction and transformation in Fe-C alloys. Metall Mater Trans B 31(5):981–991

Long M, Dong Z, Chen D, Zhang X, Zhang L (2015) Influence of cooling rate on austenite transformation and contraction of continuously cast steels. Ironmaking Steelmaking 42(4):1743281214Y.000

Maehara Y, Yasumoto K, Tomono H, Nagamichi T, Ohmori Y (1990) Surface cracking mechanism of continuously cast low carbon low alloy steel slabs. Mater Sci Technol 6(9):793–806

Jong-Jin P, Jong-Oh JO, Sun-In K, Wan-Yi K, Tae-In C, Seok-Min S et al (2007) Thermodynamics of titanium and oxygen dissolved in liquid iron equilibrated with titanium oxides. ISIJ Int 47(1):16–24

Ohnaka I (1986) Mathematical analysis of solute redistribution during solidification with diffusion in solid phase. Trans Iron Steel Inst Jpn 26(12):1045–51

El-Bealy M, Thomas BG (1996) Prediction of dendrite arm spacing for low alloy steel casting processes. Metall Mater Trans B 27(4):689–693

Clyne TW, Kurz W (1981) Solute redistribution during solidification with rapid solid state diffusion. Metall Mater Trans A 12(6):965–971

Ma W-J, Bao Y-P, Zhao L-H, Wang M (2014) Control of the precipitation of TiN inclusions in gear steels. Int J Miner Metall Mater 21(3):234-9

Liu Y, Zhang L, Duan H, Zhang Y, Luo Y, Conejo AN (2016) Extraction, thermodynamic analysis, and precipitation mechanism of MnS-TiN complex inclusions in low-sulfur steels. Metall Mater Trans A 47(6):3015–3025

Acknowledgements

This work was financially supported by the Natural Science Foundation of China (NSFC, project no. 51374260, 51504048 and 51611130062).

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Liu, T. et al. (2018). Study on the Formation and Control of TiN Inclusion in Mushy Zone for High Ti Microalloyed Steel. In: & Materials Society, T. (eds) TMS 2018 147th Annual Meeting & Exhibition Supplemental Proceedings. TMS 2018. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-72526-0_57

Download citation

DOI: https://doi.org/10.1007/978-3-319-72526-0_57

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-72525-3

Online ISBN: 978-3-319-72526-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)