Abstract

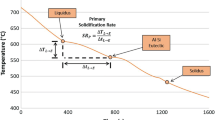

Aluminum-copper (Al–Cu) alloys have been used extensively in automotive application for several years to improve engine performance and fuel economy. Recently, Al–Ce alloys have been investigated to further increase power output by introducing increased strength and higher temperature resistant pistons and turbochargers. In this study, in situ neutron diffraction (ND) was performed to better understand the solidification kinetics of an Al–Cu base industrial alloy A206, and an Al-8 wt%Ce-10 wt%Mg alloy. Scanning electron microscopy (SEM) and FactSage™ simulations using an equilibrium mode of solidification were also conducted and related to the in situ ND results. The results for both alloys illustrate that the growth profiles as a function of temperature of the primary α-Al phase were similar to the equilibrium model simulations in FactSage™. The solidification profile for the expected Al2Cu phase in the A206 alloy was unclear due to low intensity neutron counts relative to the background. However, an approximate nucleation temperature was determined and observed to be similar to the temperature predicted from the FactSage™ simulation. The Al13CeMg6 phase in the Al–Ce–Mg alloy was not found; however, the solidification kinetics for an Al11Ce3 and a new Al–Ce–Mg secondary phase were characterized and observed to follow a dissimilar growth profile as exhibited in the FactSage™ simulation.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

N. Haghdadi, A.B. Phillion, D.M. Maijer (2015) Microstructure Characterization and Thermal Analysis of Aluminum Alloy B206 During Solidification, Metallurgical and Materials Transactions A. 46A: 2073–2081.

A. Elsayed, D. Sediako, C. Ravindran (2015) Investigation of solidification behaviour of Mg-6Al and Mg-9Al alloys using in-situ neutron diffraction, Can. Metall. Quart. 54: 17–25.

F. D’Elia, C. Ravindran, D. Sediako (2015), R. Donaberger, Solidification analysis of Al5wt-%Cu alloy using in-situ neutron diffraction, Can. Metall. Quart. 54: 9–16.

A. Lombardi, A. Elsayed, D. Sediako, C. Ravindran (2017) Analysis of the solidification characteristics of a 319 type Al alloy using in-situ neutron diffraction, Journal of Alloys and Compounds, 695: 2628–2636.

D. Sediako, F. D’Elia, A. Lombardi, A. Machin et al. (2011) Analysis of Residual Stress Profiles in the Cylinder Web Region of an As-Cast V6 Al Engine Block with Cast-In Fe Liners Using Neutron Diffraction, SAE Int. J. Mater. Manuf. 4(1):138–151, https://doi.org/10.4271/2011-01-0036.

Y. Li, Z. Shi, Y.-L. Yang, B.-M. Huang, T.-F. Chung, J.-R.Yang (2016) Experimental Investigation of tension and compression creep-aging behaviour of AA2015 with different initial tempers, Material Science and Engineering A, 657: 299–308.

W.H. Li, X.F. Bian, H.Y. Li, Y.F. Duan (2001) Interaction Between Rare Earth Ce and Hydrogen in Al- Cu Eutectic Alloy Melt, Acta Metall. Sin., 37(8): 825–828.

D. Weiss, O. Rios, Z. Sims, S. McCall, R. Ott (2017) Casting Characteristics of High Cerium Content Aluminum Alloys. Paper presented at the 146th TMS Annual Meeting, San Diego, California, 26 February–2 March 2017.

B. Chevalier, J.-L. Bobet (2001) On the Synthesis and Physical Properties of the Intermetallics CeCuAl, Intermetallics, 9(9): 835–838.

W. Kasprzak, D. Sediako, M. Sahoo, M. Walker, and I. Swainson (2010) Characterization of Hypereutectic Al-19% Si Alloy Solidification Process using In-situ Neutron Diffraction and Thermal Analysis Techniques, Proceedings of TMS, Supplemental Proceedings: Materials Processing and Properties, 1:93–104.

W. Kasprzak, D. Sediako, M. Walker, M. Sahoo, and I. Swainson (2011) Solidification Analysis of an Al-19 Pct Si Alloy Using In-situ Neutron Diffraction, Metallurgical and Materials Transactions A, 42A: 1854–1862.

D. Sediako, W. Kasprzak, I. Swainson, and O. Garlea (2011), Solidification Analysis of Al-Si Alloys Modified with Addition of Cu Using In-situ Neutron Diffraction, Proceedings of TMS, Supplemental Proceedings: Materials Fabrication Properties, Characterization and Modeling, 971:279–289.

F. D’Elia, C. Ravindran, D. Sediako, K.U. Kainer, N. Hort (2014) Hot Tearing Mechanisms of B206 Aluminum-Copper Alloy, Mater. Des. 64:44–55.

D. Sediako, W. Kasprzak, I. Swainson, and O. Garlea (2011) Aluminum Alloys: Fabrication, Characterization and Applications, Supplemental Proceedings: Materials Fabrication, Properties, Characterization, and Modeling, Paper presented at the 146th TMS Annual Meeting, San Diego, California, 26 February–2 March 2017.

Fiz K (2017). In: Inorganic Crystal Structure Database. https://icsd.fiz-karlsruhe.de/. Accessed 20 June 2017.

B. Fultz, J.M. Howe (2013) Transmission Electron Microscopy and Diffractometry of Materials, fourth ed., Springer-Verlag. https://doi.org/10.1007/978-3-540-73886-2.

D.B. Sirdeshmukh, L. Sirdeshmukh, and K.G. Subhadra (2006) Micro-and Macro-Properties of Solids, Materials Science, 80:77–133.

M.T. Hutchings, P.J. Withers, T.M. Holden, and T. Lorentzen, Introduction to the Characterization of Residual Stress by Neutron Diffraction, CRC Press, Boca Raton, 2005.

A. Elsayed, D. Sediako, C. Ravindran (2016) Solidification Analysis of a Magnesium-zinc Alloy Using In-situ Neutron Diffraction. Paper presented at 145th TMS annual Meeting, Nashville, Tennessee, 14–18 February 2016.

Acknowledgements

The authors gratefully acknowledge contribution of the sample material and expert support received from Dr. David Weiss of Eck Industries, Manitowoc, WI. We are also grateful to Canadian Nuclear Laboratories, ON, for neutron beam time used in execution of this study.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Stroh, J., Davis, T., McDougal, A., Sediako, D. (2018). In Situ Study of Solidification Kinetics of Al–Cu and Al–Ce–Mg Alloys with Application of Neutron Diffraction. In: Martin, O. (eds) Light Metals 2018. TMS 2018. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-72284-9_138

Download citation

DOI: https://doi.org/10.1007/978-3-319-72284-9_138

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-72283-2

Online ISBN: 978-3-319-72284-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)