Abstract

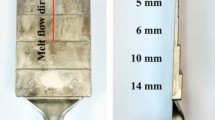

The paper describes the influence of type of structure and its parameters on mechanical properties of high-pressure die-casting (HPDC) products out of AlSi9Cu3 alloy. The dendritic structure was described using the DAS parameter—a distance between branches of dendrites of a solid α solution (silicon in aluminium), which is a measure of microstructure refinement. According to the Hall–Petch law, the smaller grain causes the better strength. The finest grained structure can be obtained by increasing the rate of heat extraction from a casting to a mould. The best results, considering the classical methods, can be achieved using the high-pressure die-casting method. Therefore, results of studies of mechanical properties of sample castings, made using the above-mentioned casting method, are presented. The sample castings (cast-on samples) were subjected to tensile tests to determine mechanical properties (tensile strength, yield strength and elongation), as well as microstructure studies, considering the DAS. Experimental-simulation validation was performed using the Procast code with the application of a micromodel in the scope of compatibility of the DAS value and yield strength.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Kujawińska, A., Rogalewicz, M., Piłacińska, M., Kochański, A., Hamrol, A., Diering, M.: Application of dominance-based rough set approach (DRSA) for quality prediction in a casting process. Metalurgija 55(4), 821–824 (2016)

Campbell, J.: Complete Casting Handbook, 2nd ed. Butterworth-Heinemann (2015)

Kurz, W., Fisher, D.J.: Fundamentals of Solidification. Trans Tech Publications (1992)

Dantzig, J.A., Rappaz, M.: Solidification. EPFL Press Lausanne, Switzerland (2009)

Legutko, S., Żak, K., Kudlacek, J.: Characteristics of geometric structure of the surface after grinding. In: The 4th International Conference on Computing and Solutions in Manufacturing Engineering 2016—CoSME’16, p. 94 (2017)

Hurtalova, L., Tillov, E., Chalupov, M.: Optical and electron microscopy study of the mechanical properties improvement on recycled AlSi9Cu3 cast alloy along the hardening. Int. Virtual J. Sci. Techn. Innov. Ind. MTM 7, 48–51 (2011)

Leal dos Santos, S., Antunes, R.A., Santos, S.F.: Influence of injection temperature and pressure on the microstructure, mechanical and corrosion properties of a AlSiCu alloy processed by HPDC. Mater. Des. 88, 1071–1081 (2015)

Niu, X.P., et al.: Vacuum assisted high pressure die casting of aluminium alloys. J. Mater. Process. Technol. 105, 119–127 (2000)

Dash, M., Makhlouf, M.: Effect of key alloying elements on the feeding characteristics of aluminum-silicon casting alloys. J. Light Met., pp. 251–265 (2001)

Martinez, E.J.D., Cisneros, M.A.G., Valtierra, S., Lacaze, J.: Effect of strontium and cooling rate upon eutectic temperatures of A319 aluminum alloy. Scr. Mater. 52, 439–443 (2005)

Trojanowska, J., Varela, M.L.R., Machado, J.: The tool supporting decision making process in area of job-shop scheduling, recent advances in information systems and technologies. In: Rocha, Á., Correia, A., Adeli, H., Reis, L., Costanzo S.: (eds.) WorldCIST, Advances in Intelligent Systems and Computing, vol. 571. Springer, pp. 490–498 (2017)

Pandilov, Z., Milecki, A., Nowak, A., Górski, F., Grajewski, D., Ciglar, D., Klaić, M., Mulc, T.: Virtual modelling and simulation of a CNC machine feed drive system. Trans. FAMENA 39(4) (2016)

Gorski, F., Zawadzki, P., Hamrol, A.: Knowledge based engineering as a condition of effective mass production of configurable products by design automation. J. Mach. Eng. 16(4), 5–30 (2016)

Szczerbicki, E. (ed.):, Cybernetics and Systems, Special issue on Soft Computing and Intelligent Systems for Industry, p. 33 (2002)

Sanna, F., Fabrizi, A., Ferraro, S., Timelli, G., Ferro, P., Bonollo, F.: Multiscale characterisation of AlSi9Cu3(Fe) die casting alloys after Cu, Mg, Zn and Sr addition. La Metall. Ital., 4 (2013)

Pietrowski, S.: Silumins. Publ. House of Lodz University of Technology, Lodz (2001)

Anza, I., Sáenz de Tejada, F.: Development of New Al-Si9Cu3 alloys for HPDC components with tailored properties. In: World Foundry Congress in Bilbao (2014)

Dobrzanski, L.A., Engineering Materials and Materials Project, WNT (2006)

Talat Lectures. http://core.materials.ac.uk/

Waszkiewicz, S., Fic, M., Perzyk, M., Szczepanik, J.: Dies and High-Pressure Die-Casting Moulds (in Polish), WNT (1983)

Kima, E.S., Leeb, K.H., Moonc, Y.H.: A feasibility study of the partial squeeze and vacuum die casting process. J. Mater. Process. Technol. 105, 42–48 (2000)

Ignaszak, Z., Hajkowski, J.: Contribution to the identification of porosity type in AlSiCu high-pressure-die-castings by experimental and virtual way. Arch. Foundry. Eng. 15, 143–151 (2015)

Acknowledgements

The research work reported here was made possible by 02/25/DSPB/4412 projects.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Hajkowski, J., Popielarski, P., Sika, R. (2018). Prediction of HPDC Casting Properties Made of AlSi9Cu3 Alloy. In: Hamrol, A., Ciszak, O., Legutko, S., Jurczyk, M. (eds) Advances in Manufacturing. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-319-68619-6_59

Download citation

DOI: https://doi.org/10.1007/978-3-319-68619-6_59

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-68618-9

Online ISBN: 978-3-319-68619-6

eBook Packages: EngineeringEngineering (R0)