Abstract

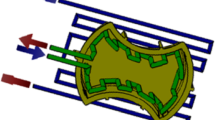

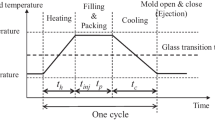

A 3D numerical study of thermal regulation system of Rapid Heat Cycle Molding (RHCM) process producing smartphone cover has been undertaken. In order to succeed an RHCM operation, so as to improve the part quality and the process productivity, heating/cooling channels design is of great importance. For this purpose, we propose in this study the optimization of geometric parameters of heating/cooling channels. The concerned geometric parameters are heating/cooling channel diameter, distance between two successive channel and distance channel–cavity surface. The thermal behaviors in mold and polymer domains are predicted by the commercial Finite Volume Analysis software Fluent 6.3.26 in cyclic transient regime. It was shown that a regular state is reached rapidly, since the second molding cycle. Thermal responses have shown that increasing heating/cooling channels diameter promotes the RHCM process productivity, but, at the same time, generates an uneven temperature distribution and consumes a significant energy. With regards to heating/cooling channels spacing, it has been demonstrated the advantage of increasing the distance between two consecutive channels. However, increasing the distance channel–cavity surface contributes to balance the temperature distribution at the cavity surface, but it affects the RHCM process productivity by increasing the molding cycle time.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Abbreviations

- Cp:

-

(heat capacity) (J kg−1 °C−1)

- D:

-

(channel diameter) (m)

- g:

-

(gravity acceleration) (m s−2)

- hh, hc :

-

(heat transfer coefficient) (W m−2 °C−1)

- Hliq :

-

(liquefaction latent heat of water) (J kg−1)

- L:

-

(length of vertical channel) (m)

- n:

-

(normal direction)

- T:

-

(temperature) (°C)

- λ:

-

(thermal conductivity) (W m−1 °C−1)

- µ:

-

(dynamic viscosity) (kg m−1s−1)

- ρ:

-

(density) (kg m−3)

- Re:

-

(Reynolds number)

- Pr:

-

(Prandtal number)

- m:

-

(mold)

- p:

-

(polymer)

- s:

-

(steam)

- w:

-

(water)

References

Autodesk simulation moldflow adviser (2002)

Chang RY, Tsau BD (1995) Experimental and theoretical studies of shrinkage, warpage and sink marks of crystalline polymer injection molded parts. Polym Eng Sci 35:1222–1230

Daniele A, Jeffrey RA (2014) Review of factors that affect Shrinkage of molded part in injection molding. Mater Manuf Process 29:662–682

Hammami M, Kria F, Baccar M (2015) Numerical study of thermal control system for rapid heat cycle injection molding process. J Process Mech Eng Part E 229:315–326

Hassan H, Regnier N, Pujos C, Arquis E, Defaye G (2010) Modeling the effect of cooling system on the shrinkage and temperature of the polymer by injection molding. Appl Therm Eng 30:1547–1557

Kria F, Hammami M, Baccar M (2017) Conformal heating/cooling channels design in rapid heat cycle molding process. Mech Ind 18:109

Li XP, Zhao GQ, Guan YJ, Ma MX (2009) Optimal design of heating channels for rapid heating cycle injection mold based on response surface and genetic algorithm. Mater Des 30:4317–4323

Lucchetta G, Fiorotto M (2013) Influence of rapid mould temperature variation on the appearance of injection-moulded parts. J Mech Eng 59:683–688

Lucchetta G, Fiorotto M, Bariani PF (2012) Influence of rapid mold temperature variation on surface topography replication and appearance of injection-molded parts. CIRP Ann Manufact Technol 61:539–542

Moldflow plastic insight release 5.0 (2002)

Rohsenow MW, Hartnett JP (1973) Handbook of heat transfer. McGraw-Hill, New York

Sleicher CA, Rousse MW (1975) A convenient correlation for heat transfer to constant and variable property fluids in turbulent pipe flow. Int J Heat Mass Transf 18:677–683

Wang G, Zhao G, Li H, Guan Y (2009) Research on a New variotherm injection molding technology and its application on the molding of a large LCD panel. Polymer-plastics technology and engineering 48(7):671–681

Wang G, Zhao G, Li H, Guan Y (2011) Research on optimization design of the heating/cooling channels for rapid heat cycle molding based on response surface methodology and constrained particle swarm optimization. Expert Syst Appl 38:6705–6719

Wang G, Zhao G, Wang X (2013) Experimental research on the effects of cavity surface temperature on surface appearance properties of the moulded part in rapid heat cycle moulding process. Int J Adv Manuf Tech 68(5–8):1293–1310

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Kria, F., Hammami, M., Baccar, M. (2018). Numerical Study of Geometric Parameters Effect on Rapid Heat Cycle Molding Process. In: Haddar, M., Chaari, F., Benamara, A., Chouchane, M., Karra, C., Aifaoui, N. (eds) Design and Modeling of Mechanical Systems—III. CMSM 2017. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-319-66697-6_112

Download citation

DOI: https://doi.org/10.1007/978-3-319-66697-6_112

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-66696-9

Online ISBN: 978-3-319-66697-6

eBook Packages: EngineeringEngineering (R0)