Abstract

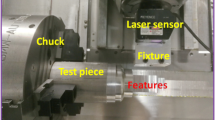

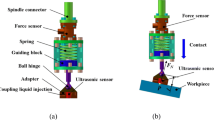

At present, for thickness inspection of sheet metal processed product having free curved surface in a manufacturing process, some typical points are selected experientially by operator. The selected points are generally measured with a point micrometer for accuracy and practicality. In this case, it is difficult to measure the thickness of whole range with non-destructive method. The study deals with an automatic measurement and evaluation system for free curved plate thickness using an industrial robot and two laser displacement sensors, called Orthros. The robot is used as a workpiece positioning device and the static dual-head thickness measuring unit composed of faced two displacement sensors measures the thickness of the workpiece with non-destructive method. The measuring procedure comprises three steps. First, the workpiece shape is measured by the system to acquire the shape data as a point cloud. Then, a thickness measuring path including the surface normal vectors and the measurement forwarding vectors is generated from the acquired shape data. Finally, the thickness is measured when the robot moves to match the calculated normal direction and the laser irradiation direction at each measuring point. The thickness data is displayed in relation to the shape data according to the needs of operator as a color map, etc. In this paper, the measurement principle and the basic performance of Orthros is described. In addition, the result of the actual thickness measurement is presented and discussed.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

The Japan Society for Technology of Plasticity (2000) Plain press forming. The Nikkan Kogyo Shimbun (in Japanese)

Ogasawara A, Naito S, Kominami H, Yamamoto T (1995) Plate thickness measuring instrument. Japanese patent disclosure H7-280526

Welch D (2010) Thickness measurements using laser triangulation. Sensors 27(4)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 Springer Nature Switzerland AG

About this paper

Cite this paper

Okugawa, Y., Asakawa, N., Okada, M. (2022). Development of Orthros, A Thickness Evaluation System for Free Curved Plate-Basic Performance Based on the Measurement Principle. In: Hinduja, S., da Silva Bartolo, P.J., Li, L., Jywe, WY. (eds) Proceedings of the 38th International MATADOR Conference. MATADOR 2015. Springer, Cham. https://doi.org/10.1007/978-3-319-64943-6_41

Download citation

DOI: https://doi.org/10.1007/978-3-319-64943-6_41

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-64942-9

Online ISBN: 978-3-319-64943-6

eBook Packages: EngineeringEngineering (R0)