Abstract

The specifics and general patterns of change in physical and physico-chemical properties of polymer-inorganic systems and effective methods of composite materials nanoengineering for light industry and construction industry have been revealed. A quantitative assessment is given of the impact of mechanoacoustic processing of calcium chloride hydrosol on the change in nanoparticles size at the dispersed phase, in parameters of nanoporous structure of cement stone formed. A method has been proposed for obtaining composite gasket materials based on formation of specific comblike structure of interphase layer of reinforcing block copolymer with the introduction of side branches in the pore spaces of the fibrous component. The method allows creating on the basis of a small set of textile carriers a wide range of gasket materials with technologically necessary level of elastic-deformation properties of the duplicated materials and a high degree of discreteness of their regulation. The substantiation of multilayer composite materials structure for the design of special garments, that allow creating new functional energy reflecting and sealing materials, is given.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

- Cement composites

- Mechanoacoustic processing

- Polymer-fibrous composite materials

- Comb copolymers

- Fusible interlining

- Elastic-deformation properties

- Power reflecting material

- Metallized coering

- Pressurizing self-glued film material

- Acrylic polymer

The present state of the domestic branches of light and the construction industry has a number of similar system problems requiring prompt solution. These include the high material and energy intensity of production; low levels of innovation and investment in the industry; high share of import materials and parts [1, p. 157]. Overcoming of technological backwardness in these production areas is impossible without the use of new composite materials that can improve the quality and reliability, increase service lives and reduce products material consumption. This raises the problem of creating scientific and technical basis for the development of technologies implemented in the garment industry and the construction industry for obtaining structural and functional materials with new improved performance characteristics based on the use of structurally modified polymer-inorganic composite materials, plasma surface modification of roll materials and polymer-cement composites, the proceeding of 3D-polymerization processes of the interphase layer composite materials formation with fibrous carrier nanoporous structure and nanodisperse mineral additives.

The range of tasks is to identify the specifics and general laws of changes in physical, chemical and physical properties of polymer-inorganic systems and effective methods of composite materials nanoengineering, characteristic features of modification of polymer-inorganic composite materials for light industry and construction industry.

Modern approaches to improvement of physical and mechanical properties of concrete are based on the formation of cement stone optimal structure, which can be achieved in particular by means of chemical modifiers that affect the physical and chemical processes of binders hardening [2, p. 55]. For this purpose the most commonly used in construction are plasticizers and hardening accelerators, of which calcium chloride is the strongest.

With the development of nanotechnology in recent years, much attention is paid to the perspective development of solid-state building materials by introducing additives in nanodispersed state and the creation of systems that incorporate nanosized elements as part of the structure. At the same time explanation of the known processes at the nanolevel can be referred to as an independent development of nanotechnology. An important place in similar processes is given to cement hydration, the initial stage of which is mixing the cement paste. According to [2, p. 55], the structural change of water by means of additives has a great influence on the process of hydration and crystalline neoplasms morphology.

Along with the chemical modification, the area of interest are the methods of mixing water activation providing its transfer to a metastable state and having a positive impact on the processes of hydration and structure formation in the obtained materials that result in improvement of their operational characteristics. Influence of electroprocessing, electromagnetic and ultrasonic [2, p. 55] activations of water mixing on properties of cement composites is widely presented in literature. At the same time data on the condition of texturing agents in the mechanically activated solutions, on the extent of transformation of the structure of the formed materials to interrelations with changes of their strength characteristics are extremely limited, making it difficult to develop scientifically proved approaches to the achievement of desired effects of improving the physical and mechanical properties of concrete structures.

The aim of the first stage of work was to carry out by high-precision methods the quantitative assessment of the influence of mechanoacoustic processing calcium chloride hydrosol, that is widely used as the modifier of cement mortars, on a dimensional change of particles of the dispersed phase, porosity parameters of the formed cement stone and its strength characteristics.

Determination of the particles size in calcium chloride hydrosol by the method of dynamic light scattering [3, p. 138; 4, p. 136] on the Zetasizer Nano ZS analyzer by Malvern Instruments Ltd has shown that mechanoacoustic processing results in discretization of the dispersed phase to the size less than 1 nm, which is maintained during technologically acceptable period of time of not less than 24 h. The reinforcing effect of mineral additives introduced into structural compositions is associated, as a rule, with the appearance in cement slurries of multiple crystallization centers that increase formation rate and uniformity of the spatial structure of curable material [5, p. 215]. Considering the nature of proportionality growth of the particles number filling the volume unit at decrease of their size, it is logical to expect that the reduction in the dimensional parameter is followed by the particles number increase in the system by 9 orders of magnitude.

The assessment of porosity and specific surface of the cement stone samples by low-temperature (77 K) adsorption and desorption of nitrogen vapor on the NOVA Series 1200e gas sorption analyzer has shown (Fig. 1) the contribution of different diameter pores in the amount of porosity. So in cement stone the dominant contribution is provided by pores with diameter of 4 nm as well as 7.0 ± 1.0 and 11.5 ± 1.5 nm. Mechanoacoustic processing of calcium chloride solution for mixing cement stone results in reduction the number of the above mentioned sized pores in the obtained cement composite and appearance of the additional band of 5.0 ± 0.5 nm dominant pore size. This proves that the use for obtaining cement mass of the mechanically activated solutions of calcium chloride provides decrease in integral indexes of porosity of the formed cement stone reducing the size of the maximal diameter of pores by 1.8 times and leveling the distribution of indexes of specific surface area and the volume of pore spaces according to pores size. Decrease of the deficiency of the cement stone structure and especially the number of mosopores having large cross sectional dimensions (up to 160 nm) reduces probability of stress concentration in the weakened structural places under the influence of external loading promoting redistribution of efforts and increase of the material mechanical stability.

Developed in the project approaches to nanostructural modification of polymer-fiber composites are of practical importance for regulating mechanical strength of various products of technical purpose (layer-frame structural materials, geotextiles, etc.) and domestic use. In production of light industry products, including textile, knitwear, leather and fur products, the most challenging technological task is to create a complex spatial form of products and ensure its safety in operation. For this purpose the sealing materials with thermoplastic adhesive are traditionally used (in terms of technology composites—prepregs) that duplicate the base material product, thereby providing the required level of shape stability of the package.

The prospects for improvement of polymer composites are primarily associated with using the methods of nanoscale molecular design of interphase layer. Broad opportunities for its specific organization open the development of synthetic approaches to obtaining the polymers of complex spatial architecture [6, p. 304; 1, p. 1328]. These include, in particular, molecular brush and comblike polymers. As shown in Fig. 2, the structure of macromolecules involves covalent attachment to the main chain of narrowly dispersed lateral radicals [7, p. 79; 8, p. 378]. Along with this the rigidity of the main valences chain is determined by the interaction of the lateral branches. Thus, flexibility of poly-α-olefins chain, polyalkylmethacrylates and polyalkylacrylates is reduced in 3 … 4 times with increasing number of monomer units in the lateral branches of 1–10. For grafted block copolymers of polyimide and polymethylmethacrylate the equilibrium hardness is increased by tens of times in comparison with the index level for the initial aromatic polyimides [9, p. 1].

The realized in the project idea provides self-assembly of the composite materials interphase layer with the penetration of lateral branches of block copolymer binder into the pore structure of fibrous component. For this purpose the project implements for the first time a set of methods of nanoconstructing of composite materials and produced on their basis packages of shape forming product details, which involves the rational combination of the following complementary techniques:

-

ultradispersing of the used polymer dispersions for their penetration into the nanoporous structure of fibrous carrier;

-

nanolayer chemical modification of the fibrous carrier structure for regulating the penetration depth of polymerizing compositions and the area of hybrid formations development;

-

polymerization process management and formation of polyblock, nanoporous and spatially oriented structures;

-

the introduction of a rational number of nanodisperse reinforcing modifiers.

Both textile and leather materials have microfibrillar structure with submicroscopic pore system, as well as mesoporous spaces between the elements of supramolecular structure (fibrils). Their dimensions in the dry state are respectively 1 … 2 and 10 … 15 nm, and increase when swollen to 3 … 7 and 25 … 35 nm. Substances having a larger size cannot penetrate into the fiber structure and are located only on the surface of material and in its interfiber spaces. Figure 3 shows that the reinforcement effect is only achieved providing the penetration of reinforcement component of polymeric binder into the fibrous material internal pore spaces (curves 3, 4) and advantageously into the submicroscopic pore system (curve 5). To determine the dimensional parameters of nanoparticles in hydrosol of reinforcing dispersions the method of dynamic light scattering has been used.

Dependences of distribution by particle size of the dispersed phase volume in the preparations of reinforcing polymer dispersions (a) and the effect of their application on the stiffness of the garment materials duplicated package (b): 1, 2 preparations of surface and macroporous dislocation; 3, 4 preparations of mesoporous dislocation; 5 preparation penetrating into the fibrous carrier submicroscopic pores

For the development of internal volume in synthetic materials, effective method of localized surface saponification in the presence of interphase catalyst-carrier, ensuring the formation of nano-sized etch pits has been suggested [10, p. 105]. Assessment of changes in surface microrelief materials by scanning electron microscopy shows the presence of multiple point “defects” with transverse dimensions of about 50 nm and to 90 nm deep. By using the method of gas adsorption it has been determined that the main growth of free volume is due to the voids with a diameter of 35 nm, which makes nanomodification conditions favorable for introduction of dispersed forms of reinforcing polymer component into the fiber structure.

The choice of reinforcing dispersions is based on the study results of copolymerization reactions with macromolecules thermoplastic adhesive (IR-spectroscopy method) and temperature intervals of their course in accordance with technological constraints (the method of differential scanning calorimetry) [11, p. 112]. According to the research results the matching pairs of adhesive and reinforcing components of polymeric binder as well as technological modes of producing the nanomodified prepregs have been determined. Reinforcement of gasket materials allows up to 20 times increase the stiffness of duplicate formative details used in the design of clothing, leather goods and footwear. The additional use of nanodisperse reinforcing additives allows up to 10-times increase the extent of discreteness in regulating the composite elastic-deformation properties and ensure the conformity of the gasket material to the designed volume and silhouette solution of products.

The substantiation of multilayer composite materials structures for special garments de-signing [12, pp. 157–161; 13, pp. 89–94] promotes creation of: (1) power reflecting materials with metal particles and development of multilayer composite heat-insulation materials with visually-optical and thermal masking properties; (2) sealing homogeneous multilayer film materials with high adhesive activity for impenetrability of details connections.

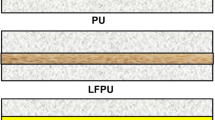

The updating metal technology of a textile basis is defined by its fibrous structure: ion-plazma metals dispersion is intended for chemical materials and proceed in low-temperature plasma soft conditions and in deep vacuum; alluvial drawing of a chemical composition with metal particles on textile cotton or mixed basis. Constructive decisions variants of heat-insulation materials are presented in Fig. 4a, b. The microporous membranous layer is executed from the thermoplastic polyurethane pitches with the sizes of holes 1.3–1.6 × 10−6 m (variant a) and water solution of the film-forming polymer with pigmentary dyes addition (variant b). The metallized layer is executed from nitride of the titan and put on a thermoplastic polyurethane pitches material by thickness till 100 nm in number of 1–2 g/m2 (variant a). The aluminium powder and acrylic aethers and pigmentary dye mixes is put on the basis instead of nitride of the titan (variant b).

The metallized covering of a material inside promotes a part of a thermal stream reflexion, which is transferred from a warm-blooded object to environment by radiation and takes away heat at the expense of evaporation [14, pp. 90–96; 15, pp. 14–17]. Textile materials with camouflaging and water-repellent finishings provide for the biological objects protection against a rain and snow. The camouflaging drawing is put on a textile basis. It can be executed as colour backgrounds, as environment backgrounds, where there are objects. It provides a visually-optical camouflage for materials in the afternoon.

The special sealing material is developed for realization of glutinous blocking technology. The thinnest layers macromolecular structurization of a film provides distinctions of their properties. The incomplete internal reflexion of IR-spectroscopy method is used as the basic studying method of a chemical compositions compound for the analysis of functional groups presence in the investigated system «an adhesive—a substratum» . It is used for an estimation of interactions character in the analyzed systems. Studying of interaction character and presence of chemical bonds of glutinous connection «a composite material—the self-glued film material» has allowed to develop and fill up system of scientific knowledge of self-glued materials application in development of glutinous technology. The formation diffusion molecular monolayer is confirmed by the microscopic researches (Fig. 5). They testify to dense thick contact as a result of phases rap-proachement up to distance of the order of 40 nm. The designed multilayer hermetic in the form of the set width rolled film possesses adhesive capacity to big substrata spectrum. It possesses constant residual stickiness property, at the most meets technological and economic requirements of products manufacture from materials with a defensive covering. The effective technology of glutinous hermetic sealing provides an impenetrability of special clothes connections for liquid environments.

Conclusions

The specifics and general patterns of change in physical and physico-chemical properties of polymer-inorganic systems and effective methods of composite materials nanoengineering have been revealed. A quantitative assessment is given of the impact of mechanoacoustic processing of calcium chloride hydrosol, that is widely used as a modifier of cement slurries, on the change in nanoparticles size at the dispersed phase, in parameters of nanoporous structure of cement stone formed and its strength characteristics.

Scientific and technological groundwork for obtaining demanded in sewing production prepregs and shape forming materials with high precision regulation of elasticity-and-deformation properties has been created. The used methods of nanostructural modification provide 3D-polymerization processes of the interphase layer composite materials formation with nanoporous structure of fibrous carrier and additional introduction of nanodisperse reinforcing additives.

The ways of updating of textile and film materials are proved. Additional functional layers formation of composite materials is realized at the expense of physical and chemical influences using on the macromolecular structure of these polymers. Special materials with the improved power reflecting and hermetic properties are created for special garments manufactures. The creation and the introduction in manufactures of new composite materials provide a reception of household and a special purpose garments with new functional characteristics.

References

Subbotin, A.V., Semenov, A.N.: Spatial self-organization of comb macromolecules. Polym. Sci. Ser. A. 49(12), 1328–1357 (2007)

Koksharov, S.A., Bazanov, A.V., Fedosov, S.V., Akulova, M.V., Slizneva, T.E.: Analysis of the influence of the calcium chloride dispersity in mechanoactivated solution on structure and characteristics of cement stone. Build. Mater. (1–2), 55–61 (2016)

Berne, B.J., Pecora, R.: Dynamic Light Scattering. 376 p. Wiley, New York (1976)

Koksharov, S.A., Kornilova, N.L., Meteleva O.V.: Metod of solvent preperation for evalutiation of nano-dispersive objects by dynamic light scattering method. Izv. Vyssh. Ucebn. Zaved. Tekhnol. Text. Promyshlennosti. (1), 167–170 (2014)

Majorov, P.M.: Concrete mixes: a formulary for builders and producers of structural materials. Rostov-on-Don: Phoenix, 461 p (2009)

Plate, N.A., Shibayev, V.P.: Comb polymers and liquid crystals. M. Chimija. 304 c (1980)

Kolbina, G.F., Shtennikova, I.N., Kononov, A.I., et al.: Effect of the molecumar architecture of side radicals on the optical properties of comb-shaped polymers. Polymer Sci. Ser. C. 49(1), 79–82 (2007)

Tsvetkov, V.N.: Rigid polymeric molecules L. 378 p. Nauka, Russia (1986)

Filippov, A.P., Belyaeva, E.V., Krasova, A.S. et al.: Synthesis and investigation of the solution behavior of graft block copolymers of polyimide and poly(methyl methacrylate). Polym Sci. Ser. A. 56(1), 1–9 (2014)

Koksharov, S.A., Kornilov, N.L., Fedosov, S.V.: Modification of polyester fibers to create composite materials with adjustable rigidity. Izv. Vyssh. Ucebn. Zaved. Khimia i Khim. Tekhnolgija. 59(6), 105–111 (2016)

Koksharov, S.A., Kornilov, N.L., Fedosov, S.V.: Developmend of rainforced composite materials with nanoporous textile carrier and the brush structure polymer interfacial layer. Rossijskij khivicheskij gurnal. 59(3), 112–123 (2015)

Fedosov, S.V., Akulova, M.V., Koksharov, S.A., Meteleva, O.V.: Theoretical Foundations of heat and mass production of advanced technology materials textile and construction industries. Proceedings of higher education institution. Text. Ind. Technol. Sci. Tech. J. 6(360), 157–161 (2015)

Chizhik, M.A., Rasskazova, M.N., Starikov, V.I.: Structural approach to modelling multi-component systems of fabric for products of clothing industry. Proceedings of higher education institution. Text. Indus. Technol. Sci. Tech. J. 6(354), 89–94 (2014)

Belova, I.U., Veselov, V.V., Korolova, C.V.: Materials with metallon-dusting for protection from hazardous production factors. Proceedings of higher education institution. Text. Ind. Technol. Sci. Tech. J. 4(346), 14–17 (2013)

Belova, I.Y., Veselov, V.V.: Technological aspects of products processing from composite materials containing special metal nanolayers. Proceedings of higher education institution. Text. Ind. Technol. Sci. Tech. J. 5(345), 90–96 (2013)

Meteleva, O.V., Dyakonova, E.V., Bondarenko, L.I.: Self-glued material as the basis of formation of impenetrable connection in clothes Proceedings of higher education institution. Text. Ind. Technol. Sci. Tech. J. 5(353), 105–108 (2014)

Acknowledgments

Researches are carried out (conducted) with the financial support of the state represented by the Ministry of Education and Science of the Russian Federation. Agreement (contract) 11.1798.2014/К.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

This chapter is published under an open access license. Please check the 'Copyright Information' section either on this page or in the PDF for details of this license and what re-use is permitted. If your intended use exceeds what is permitted by the license or if you are unable to locate the licence and re-use information, please contact the Rights and Permissions team.

Copyright information

© 2018 The Author(s)

About this paper

Cite this paper

Akulova, M.V., Koksharov, S.A., Meteleva, O.V., Fedosov, S.V. (2018). On Some Features of Nanostructural Modification of Polymer-Inorganic Composite Materials for Light Industry and for Building Industry. In: Anisimov, K., et al. Proceedings of the Scientific-Practical Conference "Research and Development - 2016". Springer, Cham. https://doi.org/10.1007/978-3-319-62870-7_52

Download citation

DOI: https://doi.org/10.1007/978-3-319-62870-7_52

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-62869-1

Online ISBN: 978-3-319-62870-7

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)