Abstract

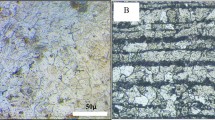

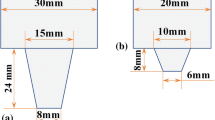

Friction stir processing (FSP) was investigated as a method for repairing cracks in 304L stainless steel. Healing feasibility was demonstrated by processing a tapered crack and a series of randomly sequenced cracks with different widths. It was possible to heal a crack that begins narrow and then progressively widens, but processing a crack that starts too wide created voids that could not be closed up. Tension and hardness testing of 304L plates processed under different conditions were performed in order to assess the effect of processing on weld and heat affected zone properties. Corrosion testing was also carried out, in order to evaluate the effect of FSP on potential sensitization of the stir zone. After 1000 h of testing in saline solution at room temperature it was found that no corrosion products formed on the base material controls or on any of the friction stir processed specimens.

Similar content being viewed by others

References

Asano K et al (1999) Weldability of neutron irradiated austenitic stainless steels. J Nucl Mater 264(1–2):1–9

Kanne WR et al (1999) Weld repair of irradiated materials. Mater Charact 43(2–3):203–214

Tsuchiya K, Kawamura H, Kalinin G (2000) Re-weldability tests of irradiated austenitic stainless steel by a TIG welding method. J Nucl Mater 283:1210–1214

Li S et al (2011) The effect of helium on welding irradiated materials. Weld J 90(1):19S–26S

Tosten MH et al (2007) Repair techniques for fusion reactor applications. Weld J 86(8):245S–252S

Feng Z, Wilkowski G (2002) Repair welding of irradiated materials: modeling of helium bubble distributions for determining crack-free welding procedures. Medium: X; Size: 8 pp

Yurioka N, Horii Y (2006) Recent developments in repair welding technologies in Japan. Sci Technol Weld Joining 11(3):255–264

Kanne WR et al (1995) Welding irradiated stainless-steel. J Nucl Mater 225:69–75

Wang CA et al (1996) The effect of an applied stress on the welding of irradiated steels. J Nucl Mater 239(1–3):85–89

Wang CA et al (1996) Welding of irradiated stainless steel. J Nucl Mater 233:213–217

Willis, E., Electrical Power Research Institute (EPRI). 2013

Li S et al (2011) The effect of helium on welding of irradiated materials. Weld J 90:7

Yang Q, Xiao BL, Ma ZY (2012) Influence of process parameters on microstructure and mechanical properties of friction-stir-processed Mg-Gd-Y-Zr casting. Metall Mater Trans a-Phys Metall Mater Sci 43A(6):2094–2109

Tsai FY, Kao PW (2012) Improvement of mechanical properties of a cast Al-Si base alloy by friction stir processing. Mater Lett 80:40–42

Sun N, Apelian D (2011) Friction stir processing of aluminum cast alloys for high performance applications. JOM 63(11):44–50

Feng XL, Liu HJ, Babu SS (2011) Effect of grain size refinement and precipitation reactions on strengthening in friction stir processed Al-Cu alloys. Scripta Mater 65(12):1057–1060

Liu FC, Ma ZY (2010) Contribution of grain boundary sliding in low-temperature superplasticity of ultrafine-grained aluminum alloys. Scripta Mater 62(3):125–128

Liechty BC, Webb BW (2008) Modeling the frictional boundary condition in friction stir welding. Int J Mach Tools Manuf 48(12–13):1474–1485

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng: R: Rep 50(1–2):1–78

Sterling CJ et al (2004) Effects of friction stir processing on the microstructure and mechanical properties of fusion Welded 304L Stainless Steel, in Research Report. Office of Naval Research. p 7

Park SHC et al (2003) Rapid formation of the sigma phase in 304 stainless steel during friction stir welding. Scripta Mater 49(12):1175–1180

Sorensen CD, Nelson TW (2005) Sigma phase formation in friction stirring of iron-nickel-chromium alloys. In: proceedings of the 7th international conference on trends in welding research. Pine Mountain, GA: ASM

Park SHC et al (2004) Corrosion resistance of friction stir welded 304 stainless steel. Scripta Mater 51(2):101–105

Acknowledgements

This work was supported by National Science Foundation grant CMMI-1405508.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Miles, M.P., Gunter, C., Liu, F., Nelson, T.W. (2017). Friction Stir Processing of 304L Stainless Steel for Crack Repair. In: Hovanski, Y., Mishra, R., Sato, Y., Upadhyay, P., Yan, D. (eds) Friction Stir Welding and Processing IX. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-52383-5_2

Download citation

DOI: https://doi.org/10.1007/978-3-319-52383-5_2

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-52382-8

Online ISBN: 978-3-319-52383-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)