Abstract

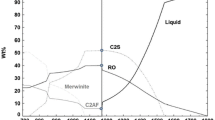

Steel slag can be an alternative in cement mineral admixture, partially as a substitute for blast furnace slag. A pyrometallugical process has been investigated to promote the chemical composition modification of molten steelmaking slag in a metallurgical reactor. Experiments were conducted by remelting 300 kg of steel slag followed by chemical modification of liquid slag. The modified slags were naturally cooled in the metallurgical reactor or cooled by steel balls. XRD and SEM analysis of slag samples revealed the relationship among chemical composition, cooling conditions and amorphous and crystalline phases. Cement samples were produced by mixing 25% of treated steelmaking slag with 75% of Portland cement, resulting in more than 280 J/g of accumulated hydration heat in 72 h, expansion lower than 0,1% in the autoclave tests and compressive strength higher than 42 MPa after 28 days. The process indicates potential to be applied as a steelmaking slag treatment.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Belhadj E, Diliberto C, Lecomte A (2012) Characterization and activation of Basic Oxygen Furnace slag. Cement and Concrete 34, 34–40.

Faraone N, Tonello G, Furlani E, Maschio S (2009) Steelmaking slag as aggregate for mortars: Effects of particle dimension on compression strength. Chemosphere 77, 1152–1156.

Li JX, Yu QJ, Wei JX, Zhang TS (2011) Structural characteristics and hydration kinetics of modified steel slag. Cement and Concrete 41, 324–329.

Tossavainen M, Engstrom F, Yang Q, Menad N, Larsson ML, Bjorkman B (2007) Characteristic of steel slag under different cooling conditions. Waste Management 27, 1335–1344.

Kriskova L, Pontikes Y, Pandelaers L, Cizer O, Jones PT, van Balen K, Blanpain B (2013) Effect of High Cooling Rates on the Mneralogy and Hydraulic Properties of Stainless Steel Slags. Metallurgical and Materials Transaction B 44, 1173–1184.

Qian GR; Sun DD; Tay JH; Lai ZY (2002) Hydrothermal reaction and autoclave stability of Mg bearing RO phase in steel slag — British Ceramic Transactions 101, 4, 159–164.

Mostafa NY, El-Hemaly SAS, Al-Wakeel EI, El-Korashy SA, Brown PW (2001) Characterization and evaluation of hydraulic activity of water-cooled slag and air-cooled slag. Cement and Concrete Research 31, 899–904.

Gautier M, Poirier J, Bodenan F, Franceschini G, Véron E (2013) Basic oxygen furnace (BOF) slag cooling: Laboratory characteristics and prediction calculations. International Journal of Mneral Processing 123, 94–101.

Ferreira Neto JB, Ribeiro TR, Lotto AA, Quarcioni VA, Chotoli FF (2014) Sistema de Modificacao de Escória, Patent application BR 10 2014 023505 1.

Xu Z, Hwang J, Greenlund R, Huang X, Luo L, Anschuetz S (2003) Quantitative Determination of Metallic Iron Content in Steel-Making Slag”. Journal of Minerals and Materials Characterization and Engineering 2, 65–70.

Solvi M, Greiveldinger B, Hoffmann M, Friederici C, Michels D (2012) Granulation of metallurgical slag. WO2012/0836 Al, pp 1–15.

Kappes H, Mchels D (2015) Dry slag granulation and energy recovery. In: Proceedings of the fourth international slag valorization symposium. Leuven, pp 39–52.

Jung SS, Sohn II (2013) Effect of FeO Concentration on the Crystallization of High-Temperature CaO-A1203-MgO-FeO Melts. Journal American Ceramic Society 96, 4, 1309–1316.

Shi CJ (2004) Steel Slag — Its Production, Processing, Characteristics and Cementitious Properties. Journal of Materials in Civil Engineering 16, 230–236.

Ferreira Neto, J. B.; Faria, J. O. G. ; Fredericci, C; Chotoli, F. F.; Silva, A. L. N; Ferraro, B. B.; Ribeiro, T. R. ; Malynowskyj, A.; Quarcioni, V. A. ; Lotto, A. A.. Modification of molten steelmaking slag for cement application. International Slag Valorisation Symposium Zero Waste, 4, 2015, Leuven. Proceedings, 2015. p. 1–7.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 TMS (The Minerals, Metals & Materials Society)

About this chapter

Cite this chapter

Neto, J.B.F. et al. (2016). Treatment of Molten Steel Slag for Cement Application. In: Kirchain, R.E., et al. REWAS 2016. Springer, Cham. https://doi.org/10.1007/978-3-319-48768-7_23

Download citation

DOI: https://doi.org/10.1007/978-3-319-48768-7_23

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-48618-5

Online ISBN: 978-3-319-48768-7

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)