Abstract

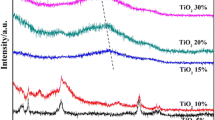

Extracting perovskite from high titanium-bearing blast furnace (BF) slag is a green and potential method to recover the second titanium resource. The non-isothermal crystallization process of perovskite in synthesized high titanium-bearing slag was studied in situ by confocal scanning laser microscope (CSLM) with cooling rate of 20 K/min. The results showed that perovskite was the primary phase formed during cooling process in the titanium-bearing synthesized slag (TiO2=23%). Perovskite started to precipitate at 1719 K and finally presented an orthogonal straight lines morphology.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Fu Nianxin, Lu Ling and Sui Zhitong, “Precipitating Behavior of Perovskite Phase in the Blast Furnace Slag Bearing Higher Titanium,” Journal of Iron and Steel Research, 10(3) (1998), 70–74.

Weng Qingqiang, “High Ti-bearing Slag Comprehensive Utilization Outline and Forecast,” Sichuan Metallurgy, 31(6) (2009), 40–43.

Wu Yucheng, Song Linyun, Li Yun, Li Yong, Li Guanghai and Zheng Zhixiang, “Preparation and Photocatalystic Activity of Ce-doped TiO2 Nanoparticles,” Journal of Synthetic Crystals, 37(2) (2008), 427–430.

Yang He, Xue Xiangxin, Zuo Liang and Yang Zhongdong, “Photocatalytic Degradation of Brilliant Red X-3B With Blast Furnace Slag Containing Titanium and Rare Earth Oxides,” Journal of the Chinese Ceramic Society, 31(9)(2003), 896–899.

Xiao Xingcheng, Jiang Weihui and Wang Yonglan, “Study on Crystallization Process of Titanate — Slag Glass Ceramics,” Glass & Enamel, 27(2)(1999), 7–11.

Liu Songli, Yang Shaoli and Gao Shizhong, “The Development of Titanium Extraction Technology in Panzhihua High Titanium-bearing Blast Furnace Slag,” Panzhihua Sci-Tech&Information, (4) (2006), 10–12.

Fang Rongli, Jin Chengchang and Xu Anyi, “Highly Valuable Utilization of Ilmenite Slag of Panzhihua Iron and Steel Company,” Cement, (2) (1998).

Sun Xiwen, Zhang Jiantao and Yang Zhiyua, “The Research of Slag Brick Using High Titaniferous Blast-Furnace Slag,” New Building Materials, (3)(2003), 5–7.

Wang Peng, Han Binqiang, Han Yanlei, Ke Changming and Li Nan, “Research on Hydration Capability of Panzhihua Iron and Steel Co. BF Slag after Extracting Silicon titanium Alloy,” Bulletin of the Chinese Ceramic Society, 27(6) (2008), 1208–1210.

Xiong Yao, Liang Bin and Li Chun, “Extraction and Separation of Titanium in Natural-cooling BF Slag,” The Chinese Journal of Process Engineering, 8(6) (2008), 1092–1097.

Liu Xiaohua, Sui Zhitong, “Pressure Acid Splitting of Ti-bearing BF Slag,” The Chinese Journal of Nonferrous Metals, 12(6) (2002), 1281–1284.

Zhou Zhiming, Zhang Binghuai and Zhu Zizong, “A Test of Titania Separation From High Titania Bearing Blast Furnace Slag,” Iron Steel Vanadium Titanium, 20(4) (1999), 35–38.

Lou Taiping, Li Yuhai, Li Liaosha and Sui Zhitong, “Study on Kinetics of Perovskite Phase Precipitate in Slag Bearing Titanium,” Journal of the Chinese Ceramic Society, 28(3) (2000), 255–258.

Z.Z. Guo, T.P. Lou, L. Zhang, L.N. Zhang and Z.T. Sui, “Precipitation and Growth of Perovskite Phase in Titanium Bearing Blast Furnace Slag,” Acta Metall.Sin(Engl.Lett.), 20(1) (2007), 9–14.

L. Zhang, L.N. Zhang, M.Y. Wang, G.Q. Li and Z.T. Sui, “Recovery of Titanium Compounds from Molten Ti-Bearing Blast Furnace Slag under the Dynamic Oxidation Condition,” Minerals Engineering, 20(2007), 684–693.

Wang Mingyu, Zhang Li, Zhang Linan and Sui Zhitong, “Characteristics Change of Ti-bearing Molten Blast Furnace Slag under Dynamic Oxidation Condition,” Nonferrous Metals, 60(2) (2008), 59–61.

Wang Mingyu, Zhang Li, Zhang Linnan, Sui Zhitong and Tu Ganfeng, “Study on Selection of the Best Titania Enrichment Phase in Titanium-Bearing Slag,” Journal of Materials and Metallurgy, 4(3) (2005), 175–177.

Joo Hyun Park, Jin Gyun Park, Dong Joon Min, Young E. Lee and Youn-Bae Kang, “In Situ Observation of the Dissolution Phenomena of SiC Particle in CaO-SiO2-MnO Slag,” Journal of the European Ceramic Society, 30(2010), 3181–3186.

J. Liu, M. Guo, P.T. Jones, F. Verhaeghe, B. Blanpain and P. Wollants, “In Situ Observation of the Direct and Indirect Dissolution of MgO Particles in Cao-Al2O3-SiO2-based Slags,” Journal of the European Ceramic Society, 27(2007), 1961–1972.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 TMS (The Minerals, Metals & Materials Society)

About this paper

Cite this paper

Lu, L., Meilong, H., Chenguang, B. (2014). Crystallization Behavior of Molten Blast Furnace Slag Using Confocal Scanning Laser Microscope. In: Mackey, P.J., Grimsey, E.J., Jones, R.T., Brooks, G.A. (eds) Celebrating the Megascale. Springer, Cham. https://doi.org/10.1007/978-3-319-48234-7_59

Download citation

DOI: https://doi.org/10.1007/978-3-319-48234-7_59

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-48591-1

Online ISBN: 978-3-319-48234-7

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)