Abstract

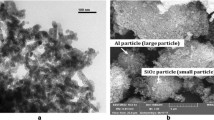

Aluminum-matrix nano-composites have been produced after incorporating various hard ceramic nanoparticles (Al2O3, AlN and SiC) and Al2O3 microparticles into liquid metal by mechanical stirring. The mechanical stirring process is optimized to obtain distribution of nanoparticles in entire volume of the liquid. However, locally, nanoparticle clusters have been found. Application of the ultrasound to the slurry containing nanoparticles resulted in significantly improved particle dispersion and reduced nanoparticle clusters density. Nano-composites have been characterized by optical and scanning electron microscopy to see dispersion enhancement. Hardness was measured to study the local mechanical properties of these composites.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

S.G. Tjong and Z.Y. Ma, “Microstructural and mechanical characteristics of in situ metal matrix composites”. Materials Science and Engineering R, 29 (2000), 49–113.

P.J. Li, E.G. Kandalova, V.I. Nikitin, A.G. Makarenko, A.R. Luts and Y.F. Zhang, “Preparation of Al-TiC composites by selfpropagating high-temperature synthesis”. Scripta Materialia, 49 (2003), 699–703.

R.J. Arsenault, “The strengthening of aluminum alloy 6061 by fiber and platelet silicon carbide”. Materials Science and Engineering, 64 (1984) 171–181.

R.J. Arsenault and N. Shi. “Dislocation generation due to differences between the coefficients of thermal expansion”. Materials Science and Engineering, 81 (1986), 175–187.

R.J. Arsenault, L. Wang and C.R. Feng, “Strenghtening of composites due to microstructural changes in the matrix”. Acta Metallurgica et Materialia, 39 (1991), 47–57.

Y. Li, Y.H. Zhao, V. Ortalan, W. Liu, R.G. Zhang, R.G. Vogt, N.D. Browning, E.J. Lavernia and J.M. Schoenung. “Investigation of aluminum-based nanocomposites with ultra-high strength”. Materials Science and Engineering A, 527 (2009), 305–316.

I.A. Ibrahim, F.A. Mohamed and E.J. Lavernia. “Particulate reinforced metal matrix composites — A review”. Journal of Material Science, 26 (1991) 1137–1156.

G.I Eskin, Yu. P. Pimenov and G.S. Makarov. “Effect of cavitation melt treatment on the structure refinement and property improvement in cast and deformed hypereutectic alloys”. Materials Science Forum, 242 (1997), 65–70.

G.I. Eskin. “Broad prospects for commercial application of the ultrasonic (cavitation) melt treatment of light alloys”. Ultrasonics Sonochemistry, 8 (2001), 319–325.

G.I. Eskin and D.G. Eskin. “Production of natural and synthesized aluminum-based composite materials with the aid of ultrasonic (cavitation) treatment of the melt”. Ultrasonics Sonochemistry, 10 (2003) 297–301.

J. Campbell. “Effects of vibration during solidification”. International Metals Review, 26 (1981), 71–108.

O.V. Abramov. “Action of high intensity ultrasound on solidifying metal”. Ultrasonics, 25 (1987) 73–82.

L. Ma, F. Chen and G. Shu, “Preparation of fine particulate — reinforced metal-matrix composites by high-intensity ultrasonic treatment”. Journal of Materials Science Letters, 14 (1995), 649–650.

B.F. Schultz, J.B. Ferguson and P.K. Rohatgi, “Microstructure and hardness of Al2O3 nanoparticle reinforced Al-Mg composites fabricated by reactive wetting and stir mixing”, Materials Science and Engineering A, 530 (2011) 87–97.

Y. Yang, J. Lan and X. Li, “Study on bulk aluminum matrix nano-composite fabricated by ultrasonic dispersion of nano-sized SiC particles in molten aluminum alloy”. Materials Science and Engineering A, 380 (2004) 378–383.

X. Li, Y. Yang and X. Cheng, “Ultrasonic —assisted fabrication of metal matrix nanocomposites”. Journal of Materials Science, 39 (2004), 3211–3212.

J. Lan, Y. Yang and X. Li, “Microstructure and microhardness of SiC nanoparticles reinforced magnesium composites fabricated by ultrasonic method”. Materials Science and Engineering A, 386 (2004), 284–290.

T. Yamasaki, Y.J. Zheng, Y. Ogino, M. Terasawa, T. Mitamura and T. Fukami, “Formation of metal-TiN/TiC nanocomposite powders by mechanical alloying and their consolidation”. Materials Science and Engineering A, 350 (2003), 168–172.

H. Yoshiki, Y. Tsunekawa, N. Mohri, M. Okumiya and I. Niimi, “Influence of ultrasonic vibration on the wettability”. Journal of Japan Institute of Light Metals, 43 (1993) 8–13.

K. Akio, O. Atshushi, K. Toshiro and T. Hiroyuki, “Fabrication process of metal matrix composite with nano-size SiC particle produced by vortex method”. Journal of Japan.Institute of Light Metals, 49 (1999) 149, 154.

Cao G, Konishi H, Li X, “Mechanical properties and microstructure of SiC-reinforced Mg-(2,4)Al-1Si nanocomposites fabricated by ultrasonic cavitation based solidification processing”. Materials Science and Engineering A, 486 (2008), 357–362.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 TMS (The Minerals, Metals & Materials Society)

About this chapter

Cite this chapter

Tamayo-Ariztondo, J., Madam, S.V., Djan, E., Eskin, D.G., Babu, N.H., Fan, Z. (2014). Nanoparticles Distribution and Mechanical Properties of Aluminum-Matrix Nano-Composites Treated with External Fields. In: Grandfield, J. (eds) Light Metals 2014. Springer, Cham. https://doi.org/10.1007/978-3-319-48144-9_236

Download citation

DOI: https://doi.org/10.1007/978-3-319-48144-9_236

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-48590-4

Online ISBN: 978-3-319-48144-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)