Abstract

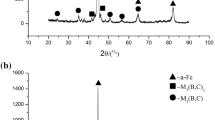

The chapter describes the effective technologies used to improve the plasticity of layers based on metal borides which determine the composite structure containing a softer component of a-solid solution and inclusions of borides positioned freely or in a specific order. The layers with composite structure lack the main disadvantage of boride layers—high brittleness—due to the created plasticity reserve. A certain amount of borides (no less than 60%) preserves the high hardness and wear-resistance. The chapter also studies the perspective methods for obtaining composite structure which are based on the use of laser and electron-beam heating. The authors analyze the formation peculiarities of different morphology under the use of boron carbide and amorphous boron as well as the influence of different heating parameters on the structure and mechanical properties of boronized layers in different brands of steels and iron casts. The chapter also includes the description of formation mechanisms for boronized layers under laser and electron-beam heating from pastes and coatings and additional processing of preliminary obtained boronized layers (combined boriding). The unique structures of boronized layers, first obtained by the authors, are presented. The obtained data allows to significantly expand the usage of boronized layers and recommend the process to be used to harden the details of machines and tools working under the conditions of dynamic loadings, e.g. shafts, chain sheaves, gears, star wheels, cam gears, stamps etc.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Krukovich M.G. Raschet evtekticheskikh kontsentratsii i temperatury v dvukh i mnogokomponentnykh sistemakh // MiTOM. №10. Pp. 9–17 [The calculation of eutectic concentrations and temperature in two- and multi-component systems].

Taran Yu.T., Mazur V.I. Struktura evtekticheskikh splavov. Moscow, 1978. 455 p. [The structure of eutectic alloys].

Novikov I.I. Metallografiya. Laboratornyi praktikum. Moscow, 1984. 125 p. [Metallurgy. Laboratory lessons].

Chudina O.V. Poverkhnostnoye legirovaniye zhelezouglerodistykh splavov s ispolzovaniem lazernogo nagreva // MiTOM. 1994. №12. C. 2–7 [Surface alloying of iron-carbon smelts using laser heating].

Draper C.W., Poate J.M. Surface Modificate and Alloy by Laser, Lin and Electron Beams // Proc. NATO Adv. Study Inst., Trevel, 27–28 Aug; 1981. New York, London. 1983. P. 385–404.

Postnikov V.S., Belova S.A., Erofeeva E.M. Obrazovaniye struktury pri lazernom karboborokhromirovanii stali X12M // Metallovedeniye i termicheskaya obrabotka metallov. 1995. №12. Pp. 13–15 [The structure formation during laser carbon-boron-chrome treatment of steel X12M].

Lysenko A.B., Kozina N.N., Miroshnichenko I.S., Borisova G.V. Osobennosti obrazovaniya struktury v stalyakh, podvergnutykh lazernomu poverkhnostnomu legirovaniyu // Metallovedeniye i termicheskaya obrabotka metallov. 1995. №12. Pp. 10–12 [The peculiaritis of structure formation in steels under laser surface alloying].

Пapшин A.M., Киpиллoв H.B. Физичecкиe и cтpyктypныe acпeкты oбpaбoтки cплaвoв кoнцeнтpиpoвaнными иcтoчникaми энepгии // Meтaллы. Parshin A.M., Kirillov N.V. Fizicheskiye i strukturnye aspekty obrabotki splavov kontsentrirovannymi istochnikami energii // Metally. 1995. №3. Pp. 21–26 [Physical and structural aspects of processing alloys with concentrated energy sources].

Kolesnikov Yu. V. Sostav dlya lazernogo boroazotirovaniya. Cert. 1482975. 30.05.89. Bul. №20 [The composition for laser boron-nitrating].

Ariely S., Shen J., Bamberger M., Dausiger F. Lazer surface alloying of steel with TiC // Surface and Coat Technol. 1991. V. 45, №1–3. P. 403–408.

Dorozhkin N.N., Kardapolova M.A., Krupskaya M.M. Metallograficheskiye i duyrometricheskiye issledovaniya poverkhnostnogo iznosa, uprochnennykh lazernoi obrabotkoi // Inzhenerno-fizicheskii zhurnal. 1998. Vol. 71, №1. Pp. 112–115 [Metallographic and durametric studies of the wear of surfaces hardened with laser treatments].

Lysenko A.B. Vliyaniye tekhnologicheskikh faktorov na sostav, stroenie i svoistva zony lazernoi khimiko-termicheskoi obrabotki // FiKHOM. 2001. №2. Pp. 25–30 [The influence of technological factors on composition, structure and properties of a laser chemical thermal processing zone].

Lakhtin Yu. M., Kogan Ya. D., Buryakin A.V. Poverkhnostnoye nasyscheniye stali borom pri vozdeistvii izlucheniya lazera // MiTOM. 1985. №11. Pp. 9–11. [Surface saturation of steel with boron during the impact of laser irradiation].

Lakhtin Yu. M., Kogan Ya.B., Zelenov A.E., Chudina O.V. Sposob lazernogo legirovaniya poverkhnosti metalla. Cert. 1557193.15.04.90. Bul. №14 [The method of laser alloying of the metal’s surface].

Kershenbaum V.Ya., Prusakov B.A., ed. Mnogoyaychnyi tolkovyi slovar’ ‘Metally. Stroeniye. Svoistva. Obrabotka’. Moscow, 1999. 710 p. [Multi-language explanatory dictionary ‘Metals. Structure. Properties. Processing’].

Abilsitov G.A., Safonov A.N., Baskov A.F. et al. Razrabotka protsessov borirovaniya stalei s pomoschyu nepreryvnogo CO-2 lazera // DAN USSR. 1989. Vol. 305, №2. Pp. 351–354 [The development of boriding processes for steels using discontinuous CO-2 laser].

Postnikov V.S., Tagirov M.N. Lazernoye borirovaniye titanovykh splavov // MiTOM. 1994. №1. Pp. 14–15 [Laser boriding of titanium alloys].

Tananko I.A., Levchenko A.A., Guiva R.T., Guiva V.A., Sittsevaya E.Yu. Lazernoye borirovaniye vysokoprochnogo chuguna // FiKHOM. 1991. №5. Pp. 89–95 [Laser boriding of resistant cast iron].

Safonov A.I., Tarasova T.V. Protsessy lazernogo legirovaniya stalei nemetallicheskimi komponentami // MSTU Bulletin. Machinery construction. 1997. №2. Pp. 69–77 [Processes of laser alloying of steels with non-metallic components].

Lyakhovich L.S., Ivanov S.A., Kartoshkin V.M. et al. Opredeleniye uslovii borirovaniya stali pri nagreve lazernym izlucheniem // MiTOM. 1985. №11. Pp. 12–14 [The determination of conditions for steel boriding under laser irradiation heating].

Bely A.V., Makushok E.M., Pobol I.L. Poverkhnostnaya uprochnyayuschaya obrabotka s primeneniem kontsentrirovannykh potokov energii. Minsk, 1990. 79 p. [Surface hardening treatment involving concentrated energy flows].

Bernstein A.M., Yandimirkin E.M. et al. Poverkhnostonye lazernoye legirovaniye stalei i chugunov // Elektronnaya obrabotka materialov. 1991. №3. C. 25–28 [Surface laser alloying of steels and cast irons].

Tananko I.A., Levchenko A.A., Guiva R.T., Guiva V.A., Sitsevaya E.Yu. Lazernoye borirovaniye vysokoprochnogo chuguna // FiKHOM. 1991. №5. Pp. 89–95 [Laser boriding of highly resistant cast iron].

Gordienko A.I., Ivashko V.V. Polucheniye boridnykh pokrytii na Ti-splavakh s pomoschyu izlucheniya nepreryvnogo CO2-lazera // Zaschitnye pokrytiya na metallakh. 1990. №24. Pp. 66–68 [Obtaining boride surface on Ti-smelts using discontinuous CO2-laser irradiation].

Safonov A.I. Osobennosti borirovaniya zheleza i stalei s pomoschyu nepreryvnogo CO2-lazera // MiTOM. 1998. №1. Pp. 5–9.

Grigoryants A.G., Safonov A.N. Metody poverkhnostoi lazernoi obraborki. Moscow, 1987. 191 p. [Methods of surface laser processing].

Mitrokhovich N.M. Obosnovaniye vybora sostava dlya borirovaniya v pastakh // Termicheskaya obrabotka i fizika metallov. Sverdlovsk, 1982. Iss. 7. Pp. 144–147 [The foundation for choosing a composition for boriding in pastes].

Postnikov V.S., Kalashnikova M.S. Issledovaniye struktury poverkhnostnogo sloya posle lazernogo legirovaniya nizkouglerodistykh konstruktsionnykh stalei // FiKHOM. 1999. №4. Pp. 47–51 [The study of the structure in surface layers after laser alloying in low-carbon construction steels].

Tosto S., Nenci F. Surface cladding and alloying of AISI 316 stainless steel on C45 plain carbon steel by electron beam // Met. et etud. sci. Rev met. 1987. V. 84, №6. P. 311–320.

Semenov A.P., Kovin I.B., Petrova I.P. et al. Metody i sredstva uprochneniya poverkhnostei detalei mashin kontsentrirovannymi potokami energii. Moscow, 1992. 404 p [Methods and means of hardening surfaces of machinery details with concentrated energy flows].

Benshou R.F. Istoriya sozdaniya i razvitiya elektronno-luchevykh tekhnologii // Vvedeniye v tekhnologiyu elektronno-luchevykh protsessov. Moscow, 1965. Pp. 7–22 [The history of creating and developing electron-beam technologies].

Rykalin N.N., Uglov A.A., Kokora A.N. Lazernaya obrabotka materialov. Moscow, 1975. 296 p [Laser processing of metals].

Pobol I.L. Ispolzovaniye elektronno-luchevogo vozdeistviya v tekhnologiyakh vtorogo pokoleniya poverkhnostei obrabotki metallicheskikh materialov // Treniye i iznos. 1993. T. 14, №3. Pp. 524–531 [The use of electron-beam impact in technologies of the second generation on the surfaces of metal materials].

Rykalin N.N., Zuev I.V., Uglov A.A. Osnovy elektronno-luchevoi obrabotki materialov. Moscow, 1978. 239 p. [Basics of electron-beam processing of materials].

Vladimirskiy A.R., Livshits V.B., Payuk V.A. O vozmozhnosti ispolzovaniya oblucheniya elektronami vysokikh energii dlya legirovaniya materialov // USSR Academy of Science Bulletin. Metals. 1988. №5. P. 128–133 [On the possibility of using high energy electron irradiation for alloying of materials].

Pobol I.L. Elektronno-luchevaya termoobrabotka metallicheskikh materialov // Itogi nauki i tekniki. 1990. Vol. 24. Pp. 90–166 [Electron-beam thermal processing of metallic materials].

Popov V.F., Gorin Yu. I. Protsessy i ustanovki elektronno-ionnoi tekhnologii. Moscow, 1988. 254 p. [Processes and settings of electron-ion technologies].

Ryazanov M.I., ed. Vzaimodeistviye zaryazhennykh chastits s tverdymi telami. Moscow, 1979. 73 p. [The interaction of charged particles with solid bodies].

Platonov P.A. Deistviye oblucheniya na strukturu i svoistva materialov. Moscow, 1971. 40 p [The impact of irradiation on the structure and properties of materials].

Konobeevsky S.T. Deistviye oblucheniya na materialy. Vvedeniye v radiatsionnoye materialovedeniye. Moscow, 1967. 401 p. [The influence of irradiation on materials. Introduction to the radiation materials science].

Didenko A.N. et al. Vozdeistviye puchkov zaryazhennykh chastits na poverkhnost metallov i splavov. Moscow, 1987. 187 p. [The influence of charged particles beams on the surfaces of metals and alloys].

Kirsanov V.V. et al. Protsessy radiatsionnogo defektoobrazovaniya v metalle. Moscow, 1985. 272 p. [Processes of radiation defect-formation in metals].

Лeймaн К., Кpиcтиaн Д. Bзaимoдeйcтвиe излyчeния c твepдымтeлoм и oбpaзoвaниe элeмeнтapныx дeфeктoв. — M.: Aтoмиздaт, 1979. — 296 c. Leiman K., Kristian D. Vzaimodeistviye izlucheniya s tverdym telom i obrazovaniye elementarnykh defektov. Moscow, 1979. 296 p. [The interaction of irradiation and solid bodies and the formation of elementary defects].

Pogrebnyak A.D., Shumakova N.I. Modifikatsiya metallichekikh pokrytii pod deistviem nizkoenergeticheskogo silnotochnogo puchka // FiKHOM. 1999. №6. Pp. 13–16 [The modification of metallic surfaces under the influence of low energy strong-flow beam].

Klimenov V.A., Ivanov Yu. F., Perevalova O.B., Proskurovskiy D.I., Torgunakov Yu. B., Rotshtein V.P., Andrien S.P. Formirovaniye struktury i mekhanizmy uprochneniya poverkhnostnykh sloev nerzhaveyuschei stali, obrabotannoi nizkoenergeticheskim silno-tochnym elektronnym puchkom // FiKHOM. 2000. №2. Pp. 41–47 [The formation of the structure and hardening mechanisms for surface layers in stainless steels processed with a low-energy strong-flow electron beam].

Pobol I.L. Issledovaniye i razrabotka metodov elektronno-luchevogo nagreva i poverkhnostnogo uprochneniya metallicheskikh izdelii. Minsk, 1987. 23 p [The study and development of methods of electron-beam heating and surface hardening of metallic goods].

Poletika I.M., Borisov M.D. Tverdost’ i iznosostoikost’ stali posle oblucheniya puchkom relyativistskikh elektronov // MiTOM. 1996. №12. Pp. 16–19 [Hardness and wear-resistance of steels after irradiation with relative electrons flow].

Sizov I.G., Smirnyagina N.N., Semenov A.P. Elektronno-luchevoye borirovaniye zhelezouglerodistykh splavov // ESSTU papers. Technical science. Ulan-Ude. 1999. Iss. 7. Pp. 95–106 [Electron-beam boriding of iron-carbon smelts].

Krukovich M.G. Razrabotka teoreticheskikh i prikladnykh aspektov upravleniya strukturoi i svoistvami borirovannykh sloev i ikh ispolzovanie pri proizvodstve transportnoi tekhniki. Moscow, 1995. 45 p. [The development of theoretical and applied aspects of controlling the structure and properties of boronized layers and their use in producing transport machinery].

Galynskaya N.N., Panich G.G. Mekhanizm formirovaniya diffuzionnykh pokrytii pri posledovatelnom nasyschenii stalei borom i khromom. Minsk, 1998. 7 p [The mechanism of the formation of diffusion surfaces during continuous boron and chrome saturation of steels].

Acimovic Sorica. Mehanizam obrazovania i rasta boriranoy sloja // Zast. mater. 1996. V. 37, №3. P. 119–120.

Trusova G.V. Mekhanizm formirovaniya, struktura i svoistva boridnykh sloev na stali. Tomsk, 1996. 17 p. [The formation mechanism, structure and properties of boride layers in steels].

Burakov V.A., Burakova N.M., Semenov A.S. Fenomenologicheskaya model lazernogo legirovaniya // Rostov-na-Donu, 1991. 22 p. [The phenomenological model for laser alloying].

Gemelli H., Gallerie A., Caillet M. Improvement of resistance to oxidation by laser alloying on tool steel // Sc. Mater. 1998. V. 39, №10. P. 1345–1352.

Verfanren rum Laserlegieren von Metallteilen mit Zubuhrung der Legierungs komponenten:№196, №196502586. 4.12.96. —. 10.6.98.

Sizov I.G., Smirnyagina N.N., Semenov A.P. Issledovaniye struktury pokrytii na osnove boridov, poluchennykh s primeneniem elektronno-luchevogo nagreva v vakuume // IV International Conference on Vacuum Technologies Proceedings. Kharkiv, 2001. Pp. 88–92 [The study of the structures of surface on the basis of borides obtained as a result of electron-beam heating in vacuum].

Semenov A.P., Smirnyagina N.N., Sizov I.G. Obrabotka poverkhnosti stali elektronnym puchkom i formirovaniye boridnykh sloev // IIIrd International Symposium “Advanced Technologies and Equipment” Proceedings. Kharkiv, 1999. Pp. 101–105 [Processing of steel surfaces with electron flow and the formation of boride layers].

Sizov I.G. Razrabotka nauchnykh osnov i tekhnologii elektronno-luchevogo borirovaniya zhelezouglerodistykh splavov s polucheniem na poverkhnosti boridov tugoplavkikh metallov. Dissertatsiya doktora tekhnicheskikh nauk. Moscow, 2003. 305 p [The development of scientific foundation and technology of electron-beam boriding of iron-carbon alloys aimed at obtaining high-melting point metal borides on the surface. Doctorate dissertation].

Semenov A.P., Sizov I.G., Smirnyagina N.N., Korobkov N.V., Tselovalnikov B.I., Vandanov A.G. Sposob elektronno-luchevogo borirovaniya stalei i chugunov. Patent №2186872 [The method of electron-beam boriding of steels and cast irons].

Smirnyagina N.N., Semenov A.P., Sizov I.G. Elektronno-luchevoye modifitsirovaniye i borirovaniye zhelezo-uglerodistykh splavov // Fizika i khimiya obrabotki materialov. 2000. №3. Pp. 45–49 [The electron-beam modification and boriding of iron-carbon alloys].

Sizov I.G., Smirnyagina N.N., Semenov A.P. Osobennosti elektronno-luchevogo borirovaniya stalei // MiTOM. 1999. №12. Pp. 8–11 [The peculiarities of electron beam boriding of steels].

Smirnyagina N.N., Sizov I.G., Semenov A.P. Issledovaniye struktury poverkhnostnykh sloev posle elektronno-luchevogo borirovaniya zhelezouglerodistykh splavov // 6th International Conference “Films and coatings 2001” Proceedings. Saint-Petersburg, 2001. Pp. 556–561 [The study of the structure of surface layers after electron-beam boriding in iron-carbon alloys].

Sizov I.G., Smirnyagina N.N., Semenov A.P. Comparativ estimation of boron layers produced by the electron beam and traditional borating // The proceedings of VI China-Russian symposium «New materials and technology». Beijin. 2001. P. 506.

Smolnikov E.A., Sarmanova L.M. Issledovaniye vozmozhnosti zhidkostnogo borirovaniya bystrorezhuschikh stalei // MiTOM. 1982. №11. Pp. 30–32 [The study of the possibility of liquid boriding of high-speed steels].

Safroshenkov A.F., Safroshenkov I.A. Tekhnologiya borirovaniya bystrorezhuschikh stalei // Univ. studies. Chernaya metallurgiya. 1997. Pp. 67–70 [The technology of boronizing high-speed steels].

Voroshnin L.G. Borirovaniye promyshlennykh stalei i chugunov. Minsk, 1981. 205 p. [Boriding of industrial steels and cast irons].

Lyakhovich L.S., Krukovich M.G., Turov Yu. V. Novoye v khimko-termicheskoi obrabotke stalei // Ekspress informatsiya. Minsk, 1976. 32 p. [New trends in chemical-thermal processing of steels].

Lyakhovich L.S., Voroshnin L.G., Vasilyev L.A., Krukovich M.G., Turov Yu. V. Nizkotemperaturnoye elektroliznoye borirovaniye // MiTOM. 1974. №2. Pp. 54–55 [Low-temperature electrolysis boriding].

Novakova A.A., Sizov I.G., Gvozdover R.S., Golubok D.S., Kiseleva T.Yu., Semenov A.P., Smirnyagina N.N., Prusakov B.A. Strukturnyi analiz borirovannykh sloev na poverkhnosti malouglerodistoi stali do i posle elektronno-luchevoi obrabotki // Poverknost. Rentgenovsiye, sinkhronotropnye i neitronnye issledovaniya. 2003. №3. Pp. 99–103 [The structural analysis of boronized layers on the surfaces of low-carbon steel before and after electron-beam processing].

A.A. Novakova, I.G. Sizov, D.S. Golubok, T.Yu. Kiseleva, P.O. Revokatov. Electron-beam boriding of low-carbon steel // Journal of Alloys and Compounds. 2004. V. 383. P. 108–112.

Sizov I.G., Smirnyagina N.N., Semenov A.P., Prusakov B.A., Novakova A.A. Sposob kombinirovannogo borirovaniya stalei. Patent Russian Federation № 2210617 [A method of combined boriding of steels].

Acimovic-Stojadinov Zorica Fashi sastav borizang sloja // Zast. Mater. 1996. V. 37, №4. P. 176–178.

Kukharev B.S., Phisenko S.P., Shabunya S.I. Matematicheskoye modelirovaniye borirovaniya zheleza // Enginerring-physical of iron. 1996. Vol. 69, №2. Pp. 187–193 [Mathematical modeling of iron boriding].

Matyunin V.M., Volkov P.V., Saidakhmedov R.Kh. et al. Opredeleniye mekhanicheskikh svoist i adgezionnoi prochnosti ionno-plazmennykh pokrytii sklerometricheskim metodom // MiTOM. 2002. №3. Pp. 36–39 [Determining mechanical properties and adhesive resistance of ion-plasma surfaces with a sclerometer method].

Kiselev A.A., Kuzmin R.N., Novakova A.A. // Pisma v ZHTF. 1986. Vol. 12. C. 32–36.

Novakova A.A., Kuzmin R.N. Messbauerovskaya konversionnaya spektroskopiya i ee primenenie. Moscow, 1989. 72 p. [Mössbauer conversion spectroscopy and its use].

Novakova A.A., Kiseleva T. Yu. Metody messbauerovskoi spektroskopii v fizike tverdogo tela. Messbauerovskii praktikum. Moscow, 2000. 30 p. [Method of Mössbauer spectroscopy in the physics of solid bodies. Mössbauer practice].

Sanchez F.H., Budnick J.I., Zhang J.D., Hines W.A., Choi M., Hasegawa R. The study of boride phase by Messbaur method // Phys. Rev. B. 1986. V. 34, №7. P. 4738–4731.

Sizov I.G., Semenov A.P., Smirnyagina N.N. On the increase of plasticity of boron layers using electron-beam boron plating // The proceedings of 5-th International Conference on Modification of Materials with Particle Beams and Plasma Flows. — Tomsk, 2000. V. 3. P. 262–266.

Grigorov P.K., Katkhanov B.B. Metodika issledovaniya khrupkosti borirovannogo sloya // Povysheniye nadezhnosti i dolgovechnosti detalei mashin. Rostov-na-Donu. 1972. Iss. XVI. Pp. 97–99 [The method of studying the brittleness of a boronized layer].

Skudnov V.A., Grigoryev I.N., Evdokimov S.V., Gavrilov L.A. Sposob otsenki plastichnosti uprochnennogo metalla. Patent №2085902. Publ. 1997. №18 [The method for evaluating the ductility of hardened metals].

Matyunin V.M. Metody i sredstva bezobraztsovoi ekspress-otsenki mekhanicheskikh svoistv konstruktsionnykh materialov. Moscow, 2001. 93 p. [Methods and means of non-sample express-evaluation of mechanical properties of construction steels].

Matyunin V.M. Metody i sredstva bezobraztsovoi operativnoi otsenki mekhanicheskikh svoistv materialov i elementov konstruktsii i mashin. Moscow, 1993. 36 p. [Methods and means of non-sample express evaluation of mechanical properties of materials and elements of constructions and machines].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Copyright information

© 2016 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Krukovich, M.G., Prusakov, B.A., Sizov, I.G. (2016). The Structure Compositeness as the Foundation for the Plasticity of Boronized Layers. In: Plasticity of Boronized Layers. Springer Series in Materials Science, vol 237. Springer, Cham. https://doi.org/10.1007/978-3-319-40012-9_9

Download citation

DOI: https://doi.org/10.1007/978-3-319-40012-9_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-40011-2

Online ISBN: 978-3-319-40012-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)