Abstract

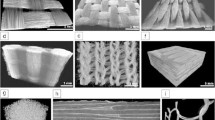

Hierarchical composites containing carbon nanotubes (CNTs) have the potential to possess improved multifunctional properties as well as unique sensing/active capabilities due to the inherent properties of CNTs (i.e., mechanical, electrical, and thermal). The purpose of this chapter is to review the current state of the art in this research area and highlight opportunities for future research. Specifically, three construction schemes used to produce CNT hierarchical composites are reviewed: dispersed systems, fiber coatings, and CNT structures. In these construction schemes, CNTs are used as a performance additive to reduce matrix mobility, as a sizing to improve adhesion between the matrix and the microscale fiber, and as the building blocks of structures such as fibers to more fully exploit the mechanical properties of CNTs, respectively. To date, research results have indicated that these strategies produce composites with improved properties, and most frequently those improved properties are mechanical properties such as strength, modulus, and fracture toughness. Based on these results, further activities aimed at understanding these property increases in terms of modeling as well as more research activity aimed at producing CNT fibers and exploiting other CNT properties will lead to improved approaches to composite design which merit the routine use of CNTs in structural composites.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Ajayan PM (1999) Nanotubes from carbon. Chem Rev 99(7):1787–1799. doi:10.1021/cr970102g

Ajayan PM (2002) Carbon nanotubes. In: Nalwa HS (ed) Nanostructured materials and nanotechnology. Academic, San Diego, pp 329–360

An F, Lu CX, Guo JH, He SQ, Lu HB, Yang Y (2011) Preparation of vertically aligned carbon nanotube arrays grown onto carbon fiber fabric and evaluating its wettability on effect of composite. Appl Surface Sci 258(3):1069–1076. doi:10.1016/j.apsusc.2011.09.003

An F, Lu CX, Li YH, Guo JH, Lu XX, Lu HB, He SQ, Yang Y (2012) Preparation and characterization of carbon nanotube-hybridized carbon fiber to reinforce epoxy composite. Mater Des 33:197–202. doi:10.1016/j.matdes.2011.07.027

An Q, Rider AN, Thostenson ET (2013) Hierarchical composite structures prepared by electrophoretic deposition of carbon nanotubes onto glass fibers. ACS Appl Mater Interfaces 5(6):2022–2032. doi:10.1021/am3028734

Arronche L, La Saponara V, Yesil S, Bayram G (2013) Impact damage sensing of multiscale composites through epoxy matrix containing carbon nanotubes. J Appl Polym Sci 128(5):2797–2806. doi:10.1002/app.38448

Ashrafi B, Guan JW, Mirjalili V, Zhang YF, Chun L, Hubert P, Simard B, Kingston CT, Bourne O, Johnston A (2011) Enhancement of mechanical performance of epoxy/carbon fiber laminate composites using single-walled carbon nanotubes. Compos Sci Technol 71(13):1569–1578. doi:10.1016/j.compscitech.2011.06.015

Ashrafi B, Diez-Pascual AM, Johnson L, Genest M, Hind S, Martinez-Rubi Y, Gonzalez-Dominguez JM, Martinez MT, Simard B, Gomez-Fatou MA, Johnston A (2012) Processing and properties of PEEK/glass fiber laminates: effect of addition of single-walled carbon nanotubes. Compos Part A Appl Sci Manuf 43(8):1267–1279. doi:10.1016/j.compositesa.2012.02.022

Barber AH, Zhao Q, Wagner HD, Baillie CA (2004) Characterization of E-glass-polypropylene interfaces using carbon nanotubes as strain sensors. Compos Sci Technol 64(13–14):1915–1919. doi:10.1016/j.compscitech.2004.02.004

Barus S, Zanetti M, Bracco P, Musso S, Chiodoni A, Tagliaferro A (2010) Influence of MWCNT morphology on dispersion and thermal properties of polyethylene nanocomposites. Polym Degrad Stab 95(5):756–762. doi:10.1016/j.polymdegradstab.2010.02.013

Behabtu N, Green MJ, Pasquali M (2008) Carbon nanotube-based neat fibers. Nano Today 3(5–6):24–34. doi:10.1016/S1748–0132(08)70062–8

Bekyarova E, Thostenson ET, Yu A, Kim H, Gao J, Tang J, Hahn HT, Chou TW, Itkis ME, Haddon RC (2007) Multiscale carbon nanotube-carbon fiber reinforcement for advanced epoxy composites. Langmuir 23(7):3970–3974. doi:10.1021/la062743p

Bethune DS, Kiang CH, deVries MS, Gorman G, Savoy R, Vasquez J, Beyers R (1993) Cobalt-catalysed growth of carbon nanotubes with single-atomic-layer walls. Nature 363(6430):605–607. doi:10.1038/363605a0

Bogdanovich AE, Bradford PD (2010) Carbon nanotube yarn and 3-D braid composites. Part I: tensile testing and mechanical properties analysis. Compos Part A Appl Sci Manuf 41(2):230–237. doi:10.1016/j.compositesa.2009.10.002

Bogdanovich A, Bradford P, Mungalov D, Fang SL, Zhang M, Baughman RH, Hudson S (2007) Fabrication and mechanical characterization of carbon nanotube yarns, 3-D braids, and their composites. SAMPE J 43(1):6–19

Böger L, Wichmann MHG, Meyer LO, Schulte K (2008) Load and health monitoring in glass fibre reinforced composites with an electrically conductive nanocomposite epoxy matrix. Compos Sci Technol 68(7–8):1886–1894. doi:10.1016/j.compscitech.2008.01.001

Boncel S, Sundaram RM, Windle AH, Koziol KKK (2011) Enhancement of the mechanical properties of directly spun CNT fibers by chemical treatment. ACS Nano 5(12):9339–9344. doi:10.1021/nn202685x

Campbell FC (2010) Structural composite materials ASM international. Materials Park, Ohio

Cao AY, Veedu VP, Li XS, Yao ZL, Ghasemi-Nejhad MN, Ajayan PM (2005) Multifunctional brushes made from carbon nanotubes. Nat Mater 4(7):540–545. doi:10.1038/nmat1415

Chen W, Shen HB, Auad ML, Huang CZ, Nutt S (2009) Basalt fiber-epoxy laminates with functionalized multi-walled carbon nanotubes. Composites Part A Appl Sci Manuf 40(8):1082–1089. doi:10.1016/j.compositesa.2009.04.027

Cipiriano BH, Kashiwagi T, Raghavan SR, Yang Y, Grulke EA, Yamamoto K, Shields JR, Douglas JF (2007) Effects of aspect ratio of MWNT on the flammability properties of polymer nanocomposites. Polymer 48(20):6086–6096. doi:10.1016/j.polymer.2007.07.070

Collins PG, Avouris P (2000) Nanotubes for electronics. Sci Am 283(6):62–69

Collins PG, Arnold MS, Avouris P (2001) Engineering carbon nanotubes and nanotube circuits using electrical breakdown. Science 292(5517):706–709. doi:10.1126/science.1058782

Cui S, Kinloch IA, Young RJ, Noe L, Monthioux M (2009) The effect of stress transfer within double-walled carbon nanotubes upon their ability to reinforce composites. Adv Mater 21(35):3591–3595. doi:10.1002/adma.200803683

da Costa EFR, Skordos AA, Partridge IK, Rezai A (2012) RTM processing and electrical performance of carbon nanotube modified epoxy/fibre composites. Compos Part A Appl Sci Manuf 43(4):593–602. doi:10.1016/j.compositesa.2011.12.019

Davis VA, Ericson LM, Parra-Vasquez ANG, Fan H, Wang YH, Prieto V, Longoria JA, Ramesh S, Saini RK, Kittrell C, Billups WE, Adams WW, Hauge RH, Smalley RE, Pasquali M (2004) Phase behavior and rheology of SWNTs in superacids. Macromolecules 37(1):154–160. doi:10.1021/ma0352328

Davis VA, Parra-Vasquez ANG, Green MJ, Rai PK, Behabtu N, Prieto V, Booker RD, Schmidt J, Kesselman E, Zhou W, Fan H, Adams WW, Hauge RH, Fischer JE, Cohen Y, Talmon Y, Smalley RE, Pasquali M (2009) True solutions of single-walled carbon nanotubes for assembly into macroscopic materials. Nat Nanotechnol 4(12):830–834. doi:10.1038/nnano.2009.302

Demczyk BG, Wang YM, Cumings J, Hetman M, Han W, Zettl A, Ritchie RO (2002) Direct mechanical measurement of the tensile strength and elastic modulus of multiwalled carbon nanotubes. Mat Sci Eng A Struct 334(1–2):173–178. doi:10.1016/S0921–5093(01)01807-X

Ericson LM, Fan H, Peng HQ, Davis VA, Zhou W, Sulpizio J, Wang YH, Booker R, Vavro J, Guthy C, Parra-Vasquez ANG, Kim MJ, Ramesh S, Saini RK, Kittrell C, Lavin G, Schmidt H, Adams WW, Billups WE, Pasquali M, Hwang WF, Hauge RH, Fischer JE, Smalley RE (2004) Macroscopic, neat, single-walled carbon nanotube fibers. Science 305(5689):1447–1450. doi:10.1126/science.1101398

Fan ZH, Hsiao KT, Advani SG (2004) Experimental investigation of dispersion during flow of multi-walled carbon nanotube/polymer suspension in fibrous porous media. Carbon 42(4):871–876. doi:10.1016/j.carbon.2004.01.067

Fan ZH, Santare MH, Advani SG (2008) Interlaminar shear strength of glass fiber reinforced epoxy composites enhanced with multi-walled carbon nanotubes. Compos Part A Appl Sci Manuf 39(3):540–554. doi:10.1016/j.compositesa.2007.11.013

Fujii M, Zhang X, Xie HQ, Ago H, Takahashi K, Ikuta T, Abe H, Shimizu T (2005) Measuring the thermal conductivity of a single carbon nanotube. Phys Rev Lett 95(6):065502. doi:10.1103/PhysRevLett.95.065502

Gao L, Thostenson ET, Zhang Z, Chou T-W (2009) Coupled carbon nanotube network and acoustic emission monitoring for sensing of damage development in composites. Carbon 47(5):1381–1388. doi:10.1016/j.carbon.2009.01.030

Garcia EJ, Wardle BL, John Hart A (2008a) Joining prepreg composite interfaces with aligned carbon nanotubes. Compos Part A Appl Sci Manuf 39(6):1065–1070. doi:10.1016/j.compositesa.2008.03.011

Garcia EJ, Wardle BL, John Hart A, Yamamoto N (2008b) Fabrication and multifunctional properties of a hybrid laminate with aligned carbon nanotubes grown In Situ. Compos Sci Technol 68(9):2034–2041. doi:10.1016/j.compscitech.2008.02.028

Godara A, Mezzo L, Luizi F, Warrier A, Lomov SV, van Vuure AW, Gorbatikh L, Moldenaers P, Verpoest I (2009) Influence of carbon nanotube reinforcement on the processing and the mechanical behaviour of carbon fiber/epoxy composites. Carbon 47(12):2914–2923. doi:10.1016/j.carbon.2009.06.039

Gojny FH, Wichmann MHG, Fiedler B, Bauhofer W, Schulte K (2005) Influence of nano-modification on the mechanical and electrical properties of conventional fibre-reinforced composites. Compos Part A Appl Sci Manuf 36(11):1525–1535. doi:10.1016/j.compositesa.2005.02.007

Gorbatikh L, Lomov SV, Verpoest I (2011) Nano-engineered composites: a multiscale approach for adding toughness to fibre reinforced composites. In: Guagliano M, Vergani L (eds) 11th international conference on the mechanical behavior of materials, vol 10. Procedia Engineering. pp 3252–3258. doi:10.1016/j.proeng.2011.04.537

Grady BP (2011) Carbon nanotube-polymer composites. Wiley, Hoboken

Guo JH, Lu CX (2012) Continuous preparation of multiscale reinforcement by electrophoretic deposition of carbon nanotubes onto carbon fiber tows. Carbon 50(8):3101–3103. doi:10.1016/j.carbon.2012.02.044

Guo JH, Lu CX, An F (2012) Effect of electrophoretically deposited carbon nanotubes on the interface of carbon fiber reinforced epoxy composite. J Mat Sci 47(6):2831–2836. doi:10.1007/s10853–011-6112–5

Hall LJ, Coluci VR, Galvao DS, Kozlov ME, Zhang M, Dantas SO, Baughman RH (2008) Sign change of Poisson's ratio for carbon nanotube sheets. Science 320(5875):504–507. doi:10.1126/science.1149815

Han J (2004) Structures and properties of carbon nanotubes. In: Meyyappan M (ed) Carbon nanotubes: science and applications. CRC, Boca Raton

He XD, Zhang FH, Wang RG, Liu WB (2007) Preparation of a carbon nanotube/carbon fiber multi-scale reinforcement by grafting multi-walled carbon nanotubes onto the fibers. Carbon 45(13):2559–2563. doi:10.1016/j.carbon.2007.08.018

Hu JB, Dong SM, Wu B, Zhang XY, Wang Z, Zhou HJ, He P, Yang JS, Li QG (2013) Mechanical and thermal properties of Cf/SiC composites reinforced with carbon nanotube grown in situ. Ceram Int 39(3):3387–3391. doi:10.1016/j.ceramint.2012.08.072

Iijima S (1991) Helical microtubules of graphitic carbon. Nature 354(6348):56–58. doi:10.1038/354056a0

Iijima S, Ichihashi T (1993) Single-shell carbon nanotubes of 1-nm diameter. Nature 363(6430):603–605. doi:10.1038/363603a0

Jana RN, Cho JW (2008) Thermal stability and molecular interaction of polyurethane nanocomposites prepared by in situ polymerization with functionalized multiwalled carbon nanotubes. J Appl Polym Sci 108(5):2857–2864. doi:10.1002/app.27895

Jayasinghe C, Chakrabarti S, Schulz MJ, Shanov V (2011) Spinning yarn from long carbon nanotube arrays. J Mat Res 26(05):645–651. doi:10.1557/jmr.2010.91

Jia JJ, Zhao JN, Xu G, Di JT, Yong ZZ, Tao YY, Fang CO, Zhang ZG, Zhang XH, Zheng LX, Li QW (2011) A comparison of the mechanical properties of fibers spun from different carbon nanotubes. Carbon 49(4):1333–1339. doi:10.1016/j.carbon.2010.11.054

Jiang K, Li Q, Fan S (2002) Nanotechnology: spinning continuous carbon nanotube yarns. Nature 419(6909):801. doi:10.1038/419801a

Jimenez-Suarez A, Campo M, Sanchez M, Romon C, Urena A (2012) Influence of the functionalization of carbon nanotubes on calendering dispersion effectiveness in a low viscosity resin for VARIM processes. Compos Part B Eng 43(8):3482–3490. doi:10.1016/j.compositesb.2011.12.009

Jo SH, Huang JY, Chen S, Xiong GY, Wang DZ, Ren ZF (2005) Field emission of carbon nanotubes grown on carbon cloth. J Vac Sci Technol B 23(6):2363–2368. doi:10.1116/1.2102970

Kashiwagi T, Du FM, Douglas JF, Winey KI, Harris RH, Shields JR (2005a) Nanoparticle networks reduce the flammability of polymer nanocomposites. Nat Mat 4(12):928–933. doi:10.1038/nmat1502

Kashiwagi T, Du FM, Winey KI, Groth KA, Shields JR, Bellayer SP, Kim H, Douglas JF (2005b) Flammability properties of polymer nanocomposites with single-walled carbon nanotubes: effects of nanotube dispersion and concentration. Polymer 46(2):471–481. doi:10.1016/j.polymer.2004.10.087

Kepple KL, Sanborn GP, Lacasse PA, Gruenberg KM, Ready WJ (2008) Improved fracture toughness of carbon fiber composite functionalized with multi walled carbon nanotubes. Carbon 46(15):2026–2033. doi:10.1016/j.carbon.2008.08.010

Kim P, Shi L, Majumdar A, McEuen PL (2001) Thermal transport measurements of individual multiwalled nanotubes. Phys Rev Lett 87(21):215502. doi:10.1103/PhysRevLett.87.215502

Kim YA, Kamio S, Tajiri T, Hayashi T, Song SM, Endo M, Terrones M, Dresselhaus MS (2007) Enhanced thermal conductivity of carbon fiber/phenolic resin composites by the introduction of carbon nanotubes. Appl Phys Lett 90(9):093125. doi:10.1063/1.2710778

Kim M, Park YB, Okoli OI, Zhang C (2009) Processing, characterization, and modeling of carbon nanotube-reinforced multiscale composites. Compos Sci Technol 69(3–4):335–342. doi:10.1016/j.compscitech.2008.10.019

Koziol K, Vilatela J, Moisala A, Motta M, Cunniff P, Sennett M, Windle A (2007) High-performance carbon nanotube fiber. Science 318(5858):1892–1895. doi:10.1126/science.1147635

Laachachi A, Vivet A, Nouet G, Ben Doudou B, Poilane C, Chen J, Bai JB, Ayachi M (2008) A chemical method to graft carbon nanotubes onto a carbon fiber. Mat Lett 62(3):394–397. doi:10.1016/j.matlet.2007.05.044

Lachman N, Wiesel E, de Villoria RG, Wardle BL, Wagner HD (2012) Interfacial load transfer in carbon nanotube/ceramic microfiber hybrid polymer composites. Compos Sci Technol 72(12):1416–1422. doi:10.1016/j.compscitech.2012.05.015

Lachman N, Qian H, Houlle M, Amadou J, Shaffer MSP, Wagner HD (2013) Fracture behavior of carbon nanotube/carbon microfiber hybrid polymer composites. J Mat Sci 48(16):5590–5595. doi:10.1007/s10853-013-7353-2

Lepro X, Lima MD, Baughman RH (2010) Spinnable carbon nanotube forests grown on thin, flexible metallic substrates. Carbon 48(12):3621–3627. doi:10.1016/j.carbon.2010.06.016

Li YL, Kinloch IA, Windle AH (2004) Direct spinning of carbon nanotube fibers from chemical vapor deposition synthesis. Science 304(5668):276–278. doi:10.1126/science.1094982

Liu K, Sun YH, Zhou RF, Zhu HY, Wang JP, Liu L, Fan SS, Jiang KL (2010) Carbon nanotube yarns with high tensile strength made by a twisting and shrinking method. Nanotechnology 21(4):045708. doi:10.1088/0957-4484/21/4/045708

Loyola BR, La Saponara V, Loh KJ (2010) In situ strain monitoring of fiber-reinforced polymers using embedded piezoresistive nanocomposites. J Mat Sci 45(24):6786–6798. doi:10.1007/s10853-010-4775-y

Loyola BR, Loh KJ, La Saponara V (2011) Static and dynamic strain monitoring of GFRP composites using carbon nanotube thin films. In: Tomizuka M, Yun CB, Giurgiutiu V, Lynch JP (eds) Sensors and smart structures technologies for civil, Mmchanical, and aerospace systems 2011, vol 7981. Proceedings of SPIE. p 798108. doi:10.1117/12.881006

Loyola BR, Zhao YJ, Loh KJ, La Saponara V (2013) The electrical response of carbon nanotube-based thin film sensors subjected to mechanical and environmental effects. Smart Mat Struct 22(2):025010. doi:10.1088/0964-1726/22/2/025010

Lu W, Zu M, Byun J-H, Kim B-S, Chou T-W (2012) State of the art of carbon nanotube fibers: opportunities and challenges. Adv Mat 24(14):1805–1833. doi:10.1002/adma.201104672

Makris TD, Giorgi R, Lisi N, Pilloni L, Salernitano E, De Riccardis MF, Carbone D (2005) Carbon nanotube growth on PAN- and pitch-based carbon fibres by HFCVD. Fullerenes Nanotubes and Carbon Nanostruct 13:383–392. doi:10.1081/fst-200039380

Mathur RB, Chatterjee S, Singh BP (2008) Growth of carbon nanotubes on carbon fibre substrates to produce hybrid/phenolic composites with improved mechanical properties. Compos Sci Technol 68(7–8):1608–1615. doi:10.1016/j.compscitech.2008.02.020

Mei L, Li YB, Wang RG, Wang C, Peng QY, He XD (2011) Multiscale carbon nanotube-carbon fiber reinforcement for advanced epoxy composites with high interfacial strength. Polym Polym Compos 19(2–3):107–112

Mitchell CA, Bahr JL, Arepalli S, Tour JM, Krishnamoorti R (2002) Dispersion of functionalized carbon nanotubes in polystyrene. Macromolecules 35(23):8825–8830. doi:10.1021/ma020890y

Moniruzzaman M, Winey KI (2006) Polymer nanocomposites containing carbon nanotubes. Macromolecules 39(16):5194–5205. doi:10.1021/ma060733p

Mora RJ, Vilatela JJ, Windle AH (2009) Properties of composites of carbon nanotube fibres. Compos Sci Technol 69(10):1558–1563. doi:10.1016/j.compscitech.2008.11.038

Motta M, Li YL, Kinloch I, Windle A (2005) Mechanical properties of continuously spun fibers of carbon nanotubes. Nano Lett 5(8):1529–1533. doi:10.1021/nl050634 +

Nie JQ, Jia YX, Qu P, Shi QR (2011) Carbon nanotube/carbon fiber multiscale composite: influence of interfacial strength on mechanical properties. J Inorg Organomet Polym Mater 21(4):937–940. doi:10.1007/s10904-011-9565-8

Parra-Vasquez ANG, Behabtu N, Green MJ, Pint CL, Young CC, Schmidt J, Kesselman E, Goyal A, Ajayan PM, Cohen Y, Talmon Y, Hauge RH, Pasquali M (2010) Spontaneous dissolution of ultralong single- and multiwalled carbon nanotubes. ACS Nano 4(7):3969–3978. doi:10.1021/nn100864v

Peigney A, Laurent C, Flahaut E, Bacsa RR, Rousset A (2001) Specific surface area of carbon nanotubes and bundles of carbon nanotubes. Carbon 39(4):507–514. doi:10.1016/S0008-6223(00)00155-X

Peng QY, He XD, Li YB, Wang C, Wang RG, Hu PA, Yan YD, Sritharan T (2012) Chemically and uniformly grafting carbon nanotubes onto carbon fibers by poly(amidoamine) for enhancing interfacial strength in carbon fiber composites. J Mat Chem 22(13):5928–5931. doi:10.1039/c2jm16723a

Pham GT, Park YB, Wang SR, Liang ZY, Wang B, Zhang C, Funchess P, Kramer L (2008) Mechanical and electrical properties of polycarbonate nanotube buckypaper composite sheets. Nanotechnology 19(32):325705. doi:10.1088/0957–4484/19/32/325705

Qian H, Bismarck A, Greenhalgh ES, Kalinka G, Shaffer MSP (2008) Hierarchical composites reinforced with carbon nanotube grafted fibers: the potential assessed at the single fiber level. Chem Mat 20(5):1862–1869. doi:10.1021/cm702782j

Qian H, Bismarck A, Greenhalgh ES, Shaffer MSP (2010a) Carbon nanotube grafted carbon fibres: a study of wetting and fibre fragmentation. Compos Part A Appl Sci Manuf 41(9):1107–1114. doi:10.1016/j.compositesa.2010.04.004

Qian H, Bismarck A, Greenhalgh ES, Shaffer MSP (2010b) Carbon nanotube grafted silica fibres: characterising the interface at the single fibre level. Compos Sci Technol 70(2):393–399. doi:10.1016/j.compscitech.2009.11.014

Qian H, Bismarck A, Greenhalgh ES, Shaffer MSP (2010c) Synthesis and characterisation of carbon nanotubes grown on silica fibres by injection CVD. Carbon 48(1):277–286. doi:10.1016/j.carbon.2009.09.029

Qian H, Greenhalgh ES, Shaffer MSP, Bismarck A (2010d) Carbon nanotube-based hierarchical composites: a review. J Mat Chem 20(23):4751–4762. doi:10.1039/c000041h

Qian H, Kalinka G, Chan KLA, Kazarian SG, Greenhalgh ES, Bismarck A, Shaffer MSP (2011) Mapping local microstructure and mechanical performance around carbon nanotube grafted silica fibres: methodologies for hierarchical composites. Nanoscale 3(11):4759–4767. doi:10.1039/c1nr10497g

Qiu JJ, Zhang C, Wang B, Liang R (2007) Carbon nanotube integrated multifunctional multiscale composites. Nanotechnology 18(27):275708. doi:10.1088/0957-4484/18/27/275708

Ramesh S, Ericson LM, Davis VA, Saini RK, Kittrell C, Pasquali M, Billups WE, Adams WW, Hauge RH, Smalley RE (2004) Dissolution of pristine single walled carbon nanotubes in superacids by direct protonation. J Phys Chem B 108(26):8794–8798. doi:10.1021/jp036971t

Rinzler AG, Liu J, Dai H, Nikolaev P, Huffman CB, Rodriguez-Macias FJ, Boul PJ, Lu AH, Heymann D, Colbert DT, Lee RS, Fischer JE, Rao AM, Eklund PC, Smalley RE (1998) Large-scale purification of single-wall carbon nanotubes: process, product, and characterization. Appl Phys a Mat Sci Proc 67(1):29–37. doi:10.1007/s003390050734

Romhany G, Szebenyi G (2009) Interlaminar crack propagation in MWCNT/fiber reinforced hybrid composites. Exp Poly Lett 3(3):145–151. doi:10.3144/expresspolymlett.2009.19

Sager RJ, Klein PJ, Lagoudas DC, Zhang Q, Liu J, Dai L, Baur JW (2009) Effect of carbon nanotubes on the interfacial shear strength of T650 carbon fiber in an epoxy matrix. Compos Sci Technol 69(7–8):898–904. doi:10.1016/j.compscitech.2008.12.021

Salinier A, Dagreou S, Leonardi F, Derail C, Navascues N (2013) Electrical, rheological and mechanical characterization of multiscale composite materials based on poly(etherimide)/short glass fibers/multiwalled carbon nanotubes. Compos Struct 102:81–89. doi:10.1016/j.compstruct.2013.02.025

Sanchez M, Campo M, Jimenez-Suarez A, Urena A (2013) Effect of the carbon nanotube functionalization on flexural properties of multiscale carbon fiber/epoxy composites manufactured by VARIM. Compos Part B Eng 45(1):1613–1619. doi:10.1016/j.compositesb.2012.09.063

Schadler LS, Giannaris SC, Ajayan PM (1998) Load transfer in carbon nanotube epoxy composites. Appl Phys Lett 73(26):3842–3844. doi:10.1063/1.122911

Schlea MR, Brown TR, Bush JR, Criss JM, Mintz EA, Shofner ML (2010) Dispersion control and characterization in multiwalled carbon nanotube and phenylethynyl-terminated imide composites. Compos Sci Technol 70(5):822–828. doi:10.1016/j.compscitech.2010.01.019

Schlea MR, Meree CE, Gerhardt RA, Mintz EA, Shofner ML (2012) Network behavior of thermosetting polyimide/multiwalled carbon nanotube composites. Polymer 53(4):1020–1027. doi:10.1016/j.polymer.2011.12.050

Schnorr JM, Swager TM (2010) Emerging applications of carbon nanotubes. Chem Mater 23(3):646–657. doi:10.1021/cm102406h

Seo MK, Park SJ (2004) A kinetic study on the thermal degradation of multi-walled carbon nanotubes-reinforced poly(propylene) composites. Macromol Mat Eng 289(4):368–374. doi:10.1002/mame.200300303

Seyhan AT, Gojny FH, Tanoglu M, Schulte K (2007) Critical aspects related to processing of carbon nano tube/unsaturated thermoset polyester nanocomposites. Eur Polym J 43(2):374–379. doi:10.1016/j.eurpolymj.2006.11.018

Sharma K, Shukla M (2012) Experimental study of mechanical properties of multiscale carbon fiber-epoxy-CNT composites. In: Fan W (ed) Manufacturing science and technology, Pts 1–8, vol 383–390. Advanced Materials Research. pp 2723–2727. doi:10.4028/www.scientific.net/AMR.383-390.2723

Shen C, Brozena AH, Wang Y (2011) Double-walled carbon nanotubes: challenges and opportunities. Nanoscale 3(2):503–518. doi:10.1039/C0NR00620C

Shimamura Y, Oshima K, Tohgo K, Fujii T, Shirasu K, Yamamoto G, Hashida T, Goto K, Ogasawara T, Naito K, Nakano T, Inoue Y (2014) Tensile mechanical properties of carbon nanotube/epoxy composite fabricated by pultrusion of carbon nanotube spun yarn preform. Compos Part A Appl Sci Manuf 62(0):32–38. doi:10.1016/j.compositesa.2014.03.011

Siddiqui NA, Sham ML, Tang BZ, Munir A, Kim JK (2009) Tensile strength of glass fibres with carbon nanotube-epoxy nanocomposite coating. Compos Part A Appl Sci Manuf 40(10):1606–1614. doi:10.1016/j.compositesa.2009.07.005

Siddiqui NA, Khan SU, Kim JK (2013) Experimental torsional shear properties of carbon fiber reinforced epoxy composites containing carbon nanotubes. Compos Struct 104:230–238. doi:10.1016/j.compstruct.2013.04.033

Singh BP, Choudhary V, Saini P, Mathur RB (2012) Designing of epoxy composites reinforced with carbon nanotubes grown carbon fiber fabric for improved electromagnetic interference shielding. AIP Adv 2(2):022151. doi:10.1063/1.4730043

Song L, Zhang H, Zhang Z, Xie SS (2007) Processing and performance improvements of SWNT paper reinforced PEEK nanocomposites. Compos Part A Appl Sci Manuf 38(2):388–392. doi:10.1016/j.compositesa.2006.03.007

Steiner SA, Li R, Wardle BL (2013) Circumventing the mechanochemical origins of strength loss in the synthesis of hierarchical carbon fibers. ACS Appl Mater Interf 5(11):4892–4903. doi:10.1021/am4006385

Sundaram RM, Koziol KKK, Windle AH (2011) Continuous direct spinning of fibers of single-walled carbon nanotubes with metallic chirality. Adv Mat 23(43):5064–5068. doi:10.1002/adma.201102754

Szleifer I, Yerushalmi-Rozen R (2005) Polymers and carbon nanotubes—dimensionality, interactions and nanotechnology. Polymer 46(19):7803–7818. doi:10.1016/j.polymer.2005.05.104

Thess A, Lee R, Nikolaev P, Dai H, Petit P, Robert J, Xu C, Lee YH, Kim SG, Rinzler AG, Colbert DT, Scuseria GE, Tomanek D, Fischer JE, Smalley RE (1996) Crystalline ropes of metallic carbon nanotubes. Science 273(5274):483–487. doi:10.1126/science.273.5274.483

Thostenson ET, Li WZ, Wang DZ, Ren ZF, Chou TW (2002) Carbon nanotube/carbon fiber hybrid multiscale composites. J Appl Phys 91(9):6034–6037. doi:10.1063/1.1466880

Thostenson ET, Li C, Chou T-W (2005) Nanocomposites in context. Compos Sci Technol 65(3–4):491–516. doi:10.1016/j.compscitech.2004.11.003

Thostenson ET, Gangloff JJ, Li CY, Byun JH (2009a) Electrical anisotropy in multiscale nanotube/fiber hybrid composites. Appl Phys Lett 95(7):073111. doi:10.1063/1.3202788

Thostenson ET, Ziaee S, Chou TW (2009b) Processing and electrical properties of carbon nanotube/vinyl ester nanocomposites. Compos Sci Technol 69(6):801–804. doi:10.1016/j.compscitech.2008.06.023

Tibbetts GG (1989a) Vapor-grown carbon fibers. In: Figueiredo JL, Bernardo CA, Baker RTK, Huttinger KJ (eds) Carbon fibers filaments and composites. Kluwer, Dordrecht

Tibbetts GG (1989b) Vapor-grown carbon fibers: status and prospects. Carbon 27(5):745–747. doi:10.1016/0008-6223(89)90208-X

Tran CD, Humphries W, Smith SM, Huynh C, Lucas S (2009) Improving the tensile strength of carbon nanotube spun yarns using a modified spinning process. Carbon 47(11):2662–2670. doi:10.1016/j.carbon.2009.05.020

Veedu VP, Cao AY, Li XS, Ma KG, Soldano C, Kar S, Ajayan PM, Ghasemi-Nejhad MN (2006) Multifunctional composites using reinforced laminae with carbon-nanotube forests. Nat Mat 5(6):457–462. doi:10.1038/nmat1650

Vilatela JJ, Windle AH (2010) Yarn-like carbon nanotube fibers. Adv Mat 22(44):4959–4963. doi:10.1002/adma.201002131

Vilatela JJ, Khare R, Windle AH (2012) The hierarchical structure and properties of multifunctional carbon nanotube fibre composites. Carbon 50(3):1227–1234. doi:10.1016/j.carbon.2011.10.040

Wang BC, Yin JS, Wang L (2013a) Structure and properties of aeronautical composites using carbon nanotubes/epoxy dispersion as nanocomposite matrix. Polym Compos 34(10):1690–1697. doi:10.1002/pc.22570

Wang BC, Zhou X, Ma KM (2013b) Fabrication and properties of CNTs/carbon fabric hybrid multiscale composites processed via resin transfer molding technique. Compos Part B Eng 46:123–129. doi:10.1016/j.compositesb.2012.10.022

Wang BC, Zhou X, Yin JS, Wang L (2013c) Investigation on some matrix-dominated properties of hybrid multiscale composites based on carbon fiber/carbon nanotube modified epoxy. J Appl Polym Sci 128(2):990–996. doi:10.1002/app.38191

Wang YQ, Ku HK, Byun JH, Song JI (2010) Optimization of deposition conditions for CNTs/carbon fiber hybrid multiscale composites via Taguchi method. In: Multi-functional materials and structures III, Pts 1 and 2, vol 123–125. Advanced Materials Research. pp 1179–1182. doi:10.4028/www.scientific.net/AMR.123-125.1179

Wichmann MHG, Sumfleth J, Gojny FH, Quaresimin M, Fiedler B, Schulte K (2006) Glass-fibre-reinforced composites with enhanced mechanical and electrical properties—Benefits and limitations of a nanoparticle modified matrix. Eng Fract Mech 73(16):2346–2359. doi:10.1016/j.engfracmech.2006.05.015

Wicks SS, de Villoria RG, Wardle BL (2010) Interlaminar and intralaminar reinforcement of composite laminates with aligned carbon nanotubes. Compos Sci Technol 70(1):20–28. doi:10.1016/j.compscitech.2009.09.001

Wu AS, Chou T-W (2012) Carbon nanotube fibers for advanced composites. Mat Today 15(7–8):302–310. doi:10.1016/S1369-7021(12)70135-9

Wu Q, Zhu W, Zhang C, Liang ZY, Wang B (2010) Study of fire retardant behavior of carbon nanotube membranes and carbon nanofiber paper in carbon fiber reinforced epoxy composites. Carbon 48(6):1799–1806. doi:10.1016/j.carbon.2010.01.023

Wu QA, Bao JW, Zhang C, Liang RC, Wang B (2011) The effect of thermal stability of carbon nanotubes on the flame retardancy of epoxy and bismaleimide/carbon fiber/buckypaper composites. J Therm Anal Calorim 103(1):237–242. doi:10.1007/s10973-010-0960-0

Yakobson BI, Samsonidze G, Samsonidze GG (2000) Atomistic theory of mechanical relaxation in fullerene nanotubes. Carbon 38(11–12):1675–1680. doi:10.1016/S0008-6223(00)00093-2

Yamamoto N, Hart AJ, Garcia EJ, Wicks SS, Duong HM, Slocum AH, Wardle BL (2009) High-yield growth and morphology control of aligned carbon nanotubes on ceramic fibers for multifunctional enhancement of structural composites. Carbon 47(3):551–560. doi:10.1016/j.carbon.2008.10.030

Yu M-F, Lourie O, Dyer MJ, Moloni K, Kelly TF, Ruoff RS (2000a) Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science 287(5453):637–640. doi:10.1126/science.287.5453.637

Yu MF, Files BS, Arepalli S, Ruoff RS (2000b) Tensile loading of ropes of single wall carbon nanotubes and their mechanical properties. Phys Rev Lett 84(24):5552–5555. doi:10.1103/PhysRevLett.84.5552

Yu Z, Brus LE (2001) (n, m) Structural assignments and chirality dependence in single-wall carbon nanotube Raman scattering. J Phys Chem B 105(29):6831–6837. doi:10.1021/jp010853t

Zhang FH, Wang RG, He XD, Wang C, Ren LN (2009a) Interfacial shearing strength and reinforcing mechanisms of an epoxy composite reinforced using a carbon nanotube/carbon fiber hybrid. J Mat Sci 44(13):3574–3577. doi:10.1007/s10853-009-3484-x

Zhang M, Atkinson KR, Baughman RH (2004) Multifunctional carbon nanotube yarns by downsizing an ancient technology. Science 306(5700):1358–1361. doi:10.1126/science.1104276

Zhang Q, Liu J, Sager R, Dai L, Baur J (2009b) Hierarchical composites of carbon nanotubes on carbon fiber: influence of growth condition on fiber tensile properties. Compos Sci Technol 69(5):594–601. doi:10.1016/j.compscitech.2008.12.002

Zhang S, Kumar S (2008) Carbon nanotubes as liquid crystals. Small 4(9):1270–1283. doi:10.1002/smll.200700082

Zhang S, Koziol KK, Kinloch IA, Windle AH (2008) Macroscopic fibers of well-aligned carbon nanotubes by wet spinning. Small 4(8):1217–1222. doi:10.1002/smll.200700998

Zhang S, Liu WB, Hao LF, Jiao WC, Yang F, Wang RG (2013) Preparation of carbon nanotube/carbon fiber hybrid fiber by combining electrophoretic deposition and sizing process for enhancing interfacial strength in carbon fiber composites. Compos Sci Technol 88:120–125. doi:10.1016/j.compscitech.2013.08.035

Zhang XF, Li QW, Holesinger TG, Arendt PN, Huang JY, Kirven PD, Clapp TG, DePaula RF, Liao XZ, Zhao YH, Zheng LX, Peterson DE, Zhu YT (2007a) Ultrastrong, stiff, and lightweight carbon-nanotube fibers. Adv Mat 19(23):4198–4201. doi:10.1002/adma.200700776

Zhang XF, Li QW, Tu Y, Li YA, Coulter JY, Zheng LX, Zhao YH, Jia QX, Peterson DE, Zhu YT (2007b) Strong carbon-nanotube fibers spun from long carbon-nanotube arrays. Small 3(2):244–248. doi:10.1002/smll.200600368

Zhao JO, Liu L, Guo QG, Shi JL, Zhai GT, Song JR, Liu ZJ (2008) Growth of carbon nanotubes on the surface of carbon fibers. Carbon 46(2):380–383. doi:10.1016/j.carbon.2007.11.021

Zhao Q, Frogley MD, Wagner HD (2001) The use of carbon nanotubes to sense matrix stresses around a single glass fiber. Compos Sci Technol 61(14):2139–2143. doi:10.1016/S0266-3538(01)00166-X

Zhou YX, Pervin F, Lewis L, Jeelani S (2008) Fabrication and characterization of carbon/epoxy composites mixed with multi-walled carbon nanotubes. Mater Sci Eng A Struct Mater Proper Microstruct Proc 475(1–2):157–165. doi:10.1016/j.msea.2007.04.043

Zhu J, Imam A, Crane R, Lozano K, Khabashesku VN, Barrera EV (2007) Processing a glass fiber reinforced vinyl ester composite with nanotube enhancement of interlaminar shear strength. Compos Sci Technol 67(7–8):1509–1517. doi:10.1016/j.compscitech.2006.07.018

Zimmer M, Cheng QF, Li S, Brooks J, Liang R, Wang B, Zhang C (2012) Comparative characterization of multiscale carbon fiber composite with long and short MWCNTs at higher weight fractions. J Nanomater 2012:532080. doi:10.1155/2012/532080

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Shofner, M. (2015). Hierarchical Composites Containing Carbon Nanotubes. In: Kim, CS., Randow, C., Sano, T. (eds) Hybrid and Hierarchical Composite Materials. Springer, Cham. https://doi.org/10.1007/978-3-319-12868-9_9

Download citation

DOI: https://doi.org/10.1007/978-3-319-12868-9_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-12867-2

Online ISBN: 978-3-319-12868-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)