Abstract

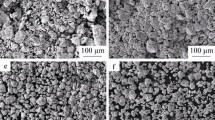

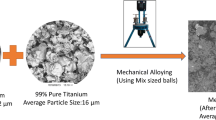

In this chapter, powder metallurgy process of TiAl nano alloys were performed via mechanical alloying (MA) of Ti-50%Al powder using planetary ball milling equipment. The characteristics of the powder samples including the compositions and microstructure changes were investigated by using X-ray diffraction and field emission scanning electron microscopy (FESEM) coupled with energy-dispersive X-ray spectroscopy (EDX). Estimation by using Scherrer equation indicated that MA performed at different duration up to 15 h have successfully refined the crystallite size from 89.51 nm of Al to 28.29, and 67.6 nm of Ti down to minimum of 17.17 nm. Longer MA duration also exhibits a better effect on the thermal behaviour of Ti-50%Al powders and micro-hardness value which is gradually increased along with MA duration.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Bhattacharya, P., Bellon, P., Averback, R.S., Hales, S., et al.: Nanocrystalline TiAl powders synthesized by high-energy ball milling: effects of milling para-meters on yield and contamination. J. Alloy. Compd. 368, 187–96 (2004)

Forouzanmehr, N., Karimzadeh, F., Enayati, M.H., et al.: Study on solid-state reactions of nanocrystalline TiAl synthesized by mechanical alloying. J. Alloy. Compd. 471, 93–97 (2009)

Goral, M., Swadzba, L., Moskal, G., Jarczyk, G., Aguilar, J., et al.: Diffusion aluminide coatings for TiAl intermetallic turbine blades. Intermetallics 19, 744–747 (2011)

Yamaguchi, M., Inui, H., Ito, K., et al.: High-temperature structural intermetallics. Acta Mater. 48, 307–322 (2000)

Kothari, K., Radhakrishnan, R., Wereley, N.M., et al.: Advances in gamma titanium aluminides and their manufacturing techniques. Prog. Aerosp. Sci. 55, 1–16 (2012)

GE-Aviation:Genx.GE.[Online] (2007). http://www.Geae.Com/Engines/Commercial/Genx/S

Hu, D.: Effect of composition on grain refinement in TiAl-based alloys. Intermetallics 9, 1037–1043 (2001)

Cuevas, F.G., Cintas, J., Montes, J.M., Gallardo, J.M., et al.: Al–Ti powder produced through mechanical alloying for different times. J. Mater. Sci. 41, 8339–8346 (2006)

Bin, F.W., Wen, L.X., Fei, S.H., Feng, D.Y., et al.: Characterization of Ti-50%Al composite powder synthesized by high energy ball milling. Trans. Non-Ferrous Met. Soc. China 21, 333–337 (2011)

Farhang, M.R., Kamali, A.R., Samani, M.N., et al.: Effects of mechanical alloying on the characteristics of a nanocrystalline Ti–50 at.%Al during hot pressing consolidation. Mater. Sci. Eng., B 168, 136–141 (2010)

Wen, L.X., Fei, S.H., Bin, F.W., Feng, D.Y., et al.: Structure and morphology of Ti-Al composite powders treated by mechanical alloying. Trans. Non-Ferrous Met. Soc. China 21, 338–341 (2011)

Gabbitas, B., Cao, P., Raynova, S., Zhang, D., et al.: Microstructural evolution during mechanical milling of Ti/Al powder mixture and production of inter-metallic TiAl cathode target. J. Mater. Sci. 47, 1234–1243 (2012)

Fadeeva, V.I., Leonov, A.V., Szewczak, E., Matyja, H., et al.: Structural defects and thermal stability of Ti(Al) solid solution obtained by mechanical alloying. Mater. Sci. Eng., A 242, 230–234 (1998)

Acknowledgement

This work was supported by UMP Research Grant under research project UMP RDU 100370.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Al-Dabbagh, J.B., Tahar, R.M., Ishak, M., Harun, S.A. (2014). Synthesis and Characterization of Nano Ti-50%Al by Mechanical Alloying. In: Öchsner, A., Altenbach, H. (eds) Design and Computation of Modern Engineering Materials. Advanced Structured Materials, vol 54. Springer, Cham. https://doi.org/10.1007/978-3-319-07383-5_23

Download citation

DOI: https://doi.org/10.1007/978-3-319-07383-5_23

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-07382-8

Online ISBN: 978-3-319-07383-5

eBook Packages: EngineeringEngineering (R0)