Abstract

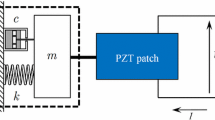

Shaft crack detection is a very serious problem and machines that are suspected of having a crack should be carefully and continuously monitored. The importance attributed to this problem is addressed to the serious consequences when cracks are not early identified in rotating systems. Although there are no statistical studies that account for the exact dimension of the damage caused by cracks in rotating shafts, estimations reveal that approximately $1 billion were expended in repairs, exchanges, loss of production, etc., in electrical industries, nuclear, and conventional, since the 1970s. Significant research effort has been directed in recent years to online monitoring techniques, i.e., based on vibration signals measured during rotor operation. However, most of these techniques are able to only detect deep cracks. In this context, the aim of this paper relies on the detection of incipient faults in rotating shafts by using the so-called electromechanical impedance method. Basically, this structural health monitoring technique—SHM monitors changes in the electric impedance of piezoelectric transducers bonded to (or embedded into) the host structure, through specific mathematic equations, the so-called damage metrics, to detect damage. This is possible since that the electrical impedance of the transducer is directly related to the mechanical impedance of the structure. Previously, successful experimental tests were performed in a horizontal rotor supported by roller bearings in which PZT patches were bonded along the rotor shaft. Although successful, the use of rigid PZT patches seems to be disadvantageous. Aiming at overcoming the drawbacks previously faced, in this contribution flexible transducers (MFC—macro fiber composites) are bonded along the shaft. A small mass was added on the shaft to simulate a fault condition (small structural modification). The technique was validated for the rotor under operation.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Doebling SW, Farrar CR, Prime MB (1998) A summary review of vibration-based damage identification methods. Shock Vib Dig 30(2):91–105

Darpe AK, Gupta K, Chawla A (2004) Coupled bending, longitudinal and torsional vibrations of a cracked rotor. J Sound Vib 269(1):33–60

Sawicki JT, Storozhev DL, Lekki JD (2011) Exploration of NDE properties of AMB supported rotors for structural damage detection. J Eng Gas Turbines Power 133(1):1–9

Dimarogonas AD (1996) Vibration of cracked structures: a state of the art review. Eng Fract Mech 55(5):831–857

Bently DE, Hatch CT (2002) Fundamentals of rotating machinery diagnostics. Bently Pressurized Bearing Company, Minden

Bachschmid N, Pennacchi P, Tanzi E (2010) Cracked rotors: a survey on static and dynamic behaviour including modelling and diagnosis. Springer, London

Bachschmid N, Pennacchi P, Tanzi E, Vania A (2001) Identification of transverse crack position and depth in rotor systems. Meccanica 35(1):563–582

Sekhar AS (2003) Crack identification in a rotor system: a model-based approach. J Sound Vib 270(1):887–902

Kulesza Z, Sawicki JT (2010) Auxiliary state variables for rotor crack detection. J Vib Control 17(6):857–872

Sawicki JT, Storozhev DL, Lekki JD (2011) Exploration of NDE properties of AMB supported rotors for structural damage detection. J Eng Gas Turbines Power 133(1):1–9

Mani G, Quinn DD, Kasarda M (2006) Active health monitoring in a rotating cracked shaft using active magnetic bearings as force actuators. J Sound Vib 294(1):454–465

Cavalini Jr AA, Finzi Neto RM, Steffen Jr V (2014) Fault detection in a rotating machine by using the electromechanical impedance method. In: XXXIIth conference and exposition on structural dynamics, IMAC 2014, Orlando, FL, USA

Butt L, Day S, Weaver J et al (2010) Wing morphing design utilizing macro fiber composite, Virginia Tech report

Park G, Inman DJ (2005) Impedance-based structural health monitoring. In: Damage prognosis for aerospace, civil and mechanical system, Wiley, New York

Park G, Sohn H, Farrar CR et al (2003) Overview of piezoelectric impedance-based health monitoring and path forward. Shock Vib Dig 35(6):451–463

Liang C, Sun FP, Rogers CA (1994) Coupled electromechanical analysis of adaptive material systems: determination of the actuator power consumption and system energy transfer. J Intell Mater Syst Struct 5(1):12–20

Chaudhry Z, Joseph T, Sun F et al (1995) Local-area health monitoring of aircraft via piezoelectric actuator-sensor patches. In: SPIE conference, smart structures and integrated systems, San Diego, CA, USA

Park G, Cudney H, Inman DJ (2000) An integrated health monitoring technique using structural impedance sensors. J Intell Mater Syst Struct 11(6):448–455

Giurgiutiu V, Zagrai AN, Bao J et al (2003) Active sensors for health monitoring of aging aerospace structures. Int J Condition Monit Diagn Eng Manage 6(1):3–21

Moura Jr JRV, Steffen Jr V (2004) Impedance-based health monitoring: frequency band evaluation. In: XXIIth conference and exposition on structural dynamics, IMAC 2004, Dearborn, MI, USA

Peairs DM (2006) High frequency modeling and experimental analysis for implementation of impedance-based structural health monitoring. Ph.D. thesis, Virginia Polytechnic Institute and State University, Virginia, p 150

Raju V (1997) Implementing impedance-based health monitoring. Ph.D. thesis, Virginia Polytechnic Institute and State University, Virginia, p 224

Park G, Kabeya K, Cudney HH et al (1999) Impedance-based structural health monitoring for temperature varying applications. JSME Int J 42(2):249–258

Inman DJ, Farrar CR, Lopes V Jr et al (2005) Damage prognosis: for aerospace, civil and mechanical systems. Wiley, New York

Giurgiutiu V, Zagrai A (2005) Damage detection in thin plates and aerospace structure with the electro-mechanical impedance method. Struct Health Monit 4(2):99–118

Acknowledgments

The authors are thankful to the Brazilian Research Agencies FAPEMIG and CNPq (INCT-EIE) and also to CAPES for the financial support provided for this research work.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this paper

Cite this paper

Cavalini, A.A., Finzi Neto, R.M., Steffen, V. (2015). Fault Detection in a Rotating Machine by Using the Electromechanical Impedance Method. In: Pennacchi, P. (eds) Proceedings of the 9th IFToMM International Conference on Rotor Dynamics. Mechanisms and Machine Science, vol 21. Springer, Cham. https://doi.org/10.1007/978-3-319-06590-8_57

Download citation

DOI: https://doi.org/10.1007/978-3-319-06590-8_57

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-06589-2

Online ISBN: 978-3-319-06590-8

eBook Packages: EngineeringEngineering (R0)