Abstract

Considering the rising energy needs and the depletion of conventional energy sources, microgrid systems combining wind energy and solar photovoltaic power with diesel generators are promising and considered economically viable for usage. To evaluate system cost and dependability, optimizing the size of microgrid system elements, including energy storage systems connected with the principal network, is crucial. In this line, a study has already been performed using a uni-objective optimization approach for the techno-economic sizing of a microgrid. It was noted that, despite the economic criterion, the environmental criterion can have a considerable impact on the elements constructing the microgrid system. In this paper, two multi-objective optimization approaches are proposed, including a non-dominated sorting genetic algorithm (NSGA-II) and the Pareto Search algorithm (PS) for the eco-environmental design of a microgrid system. The k-means clustering of the non-dominated point on the Pareto front has delivered three categories of scenarios: best economic, best environmental, and trade-off. Energy management, considering the three cases, has been applied to the microgrid over a period of 24 h to evaluate the impact of system design on the energy production system’s behavior.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Renewable energies are the main substitute for fossil fuels responsible for greenhouse gas (GHG) emissions [1], with investments totaling 350 billion euros in 2021. Solar and wind energy supply more than 10% of the world’s electricity, predicted to have a 15-18% share by 2050 [2]. The need for a sustainable energy system is increasing due to overpopulation, industrialization, and urbanization. Renewable energy sources must be pursued due to rising costs and energy security issues [3, 4]. Microgrid systems powered by renewable energy are the best option for remote communities [5]. The worldwide microgrid market exceeded 14.3 billion dollars in 2021 and is expected to reach 43.9 billion US dollars in 2028 [6]. Microgrid systems provide electricity in a reliable, secure, flexible, cost-effective, and sustainable manner, but must be well-sized and monitored to maintain reliability and keep costs low [7].

The use of optimization to design a microgrid system has been widely explained by researchers. Recently, meta-heuristic approaches have been frequently used as a single and a multi-objective approach for the optimal design of a microgrid hybrid renewable power plant in a clean energy production system, including several types of distributed generators arranged in Direct Current (DC bus), Alternative Current (AC bus), or hybrid DC/AC busses configurations, considering the whole system as a standalone or grid-connected system. However, in terms of constraints consideration, the economic and environmental implications are the main criterion, despite other technical considerations such as power losses. On [8, 9], several single-objective approaches have been studied. Nevertheless, some multi-objective techniques have been employed in the literature in accordance with this work. For instance, a Multiobjective Particle Swarm Optimization (MOPSO) has been applied to minimize cost, carbon emissions, energy use, and power use in [10]. The same approach has been used by Sellami et al. [11], to reduce network losses and increase efficiency. Non-dominated Sorting Genetic Algorithm II (NSGA-II) [18], has been used on [12, 13] to optimize both cost of operation and the rate of consumption of renewable energy, and the same optimization method has been used on [14] to increase the rate of oxygen production, short payback time and lower overall cost inside a microgrid system. An enhanced Differential Evolution (DE) have been used in [15] for the multi-objective optimal sizing of a hybrid micro-grid system considering technical-economic and social factors. In a Stand-Alone Marine Context, a microgrid has been sized by Zhu et al. [16] using an improved multi-objective grey wolf optimizer based on the Halton Sequence and Social Motivation Strategy (HSMGWO).

The study described in this paper is a continuation of [8], in which uni-evolutionary optimization methods, including the Genetic Algorithm (GA) and Particle Swarm Optimization (PSO), were used to achieve the optimal size of a hybrid energy system based on renewable energy. In addition to the technical-economic objective function, the environmental criterion describing the carbon emissions during the manufacture of microgrid components has been taken into account in this work. As a result, a multi-objective optimization problem emerges from the situation. The case study has been applied to the campus de Santa Apolónia, located in Bragança, Portugal.

The main contributions of this paper are organized as the following:

-

1.

Optimal allocation of micro-grid elements subject to technical-economic end environmental consideration.

-

2.

Application of two Multi-optimization approaches including, the non-dominated sorting genetic algorithm (NSGA-II) and the Pareto Search algorithm (PS).

-

3.

Identification of configurations scenario as best economic, best environmental, and trade-off by using the k-means clustering approach.

-

4.

Identification of the microgrid power flow behavior considering all identified scenarios.

The rest of the paper is organized as follows: Sect. 2 describes the adopted configuration of the microgrid system. In Sect. 3, the meteorological and consumption data of microgrid users are presented. The generators used to constitute the microgrid system are defined in Sect. 4. The optimal sizing of the microgrid is formulated as result of multi-objective functions in Sect. 5. The adopted sizing methodology is explained in Sect. 6. The results of the simulation and their discussion are presented in Sect. 7. Section 8 summarises the findings of the paper and proposes guidelines for future work.

2 Microgrid Arrangement

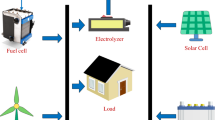

The microgrid configuration proposed in this study is the AC/DC architecture shown in Fig. 1.

The microgrid configuration includes two renewable resources: photovoltaic and wind turbines. Through a common coupling point, the microgrid is connected to the main grid, which acts as a buffer. In the event of a blackout, the diesel group connected to the AC bus is employed as a last-resort solution. The battery system connects to the DC bus in a bidirectional manner, and a bi-directional converter allows energy to flow between the two buses in both directions. Control and energy management technologies are used to ensure the flow of energy and supervision of the microgrid power quality. Microgrids that combine AC and DC power provide harmonic control, economic viability, and voltage transformation, but have drawbacks such as safety and unit coordination [9].

3 Study Data Description

Weather data is essential for sizing a microgrid, as weather mistakes can lead to errors in real operations and larger initial investments. In this study, the Polytechnic Institute of Bragança (IPB), located in the north region of Portugal (Latitude: 41.8072, Longitude: \(-6.75919\) 41o 48’ 26” North, 6o 45’ 33” West, with an elevation of 690 m), was the location of the study case. A sequence of measurement series, including average solar irradiation, wind speed, and temperature data for one year (from January 1, 2019, to December 31, 2019), as well as the average load data, have been gathered. Figure 2 represents the profile of data mentioned above. Table 1 describes the critical values of the weather data set, including the minimal value, maximal value, average value, and standard deviation.

4 System Modeling

The work [8] is the main inspiration of this study that describes the rationale behind the concepts and technology selected. For this reason, the equipment modeling of photovoltaic systems, wind turbines, battery systems, and diesel generators is assumed the same as in [8]. The new contribution of this work is the connection of the microgrid to the main grid which is presented in the following sections.

4.1 Main Grid

The main grid with microgrid can operate bi-directionally according to three scenarios as follow, where \(P_{pv}^{t}\), \(P_{wt}^{t}\) are the total active power output of photovoltaic panels, and wind turbines. E(t), is the energy delivered from/to the energy storage system in an hour t and \(P_{load}\) is the total load power, \(\varDelta _{t}\) is the step time between two periods in this case it is considered 1 h. All defined parameters are widely explained on [15].

-

The first scenario occurs when the power verifies the following relation:

$$\begin{aligned} P_{pv}^{t}(t) + P_{wt}^{t}(t) + \frac{E(t)}{\varDelta _{t} } = P_{load}(t) \end{aligned}$$(1)In this case, the main grid has no interaction with the microgrid in terms of reception or feeding.

-

The second scenario occurs when the following relationship is verified:

$$\begin{aligned} P_{pv}^{t}(t)+ P_{wt}^{t}(t) + \frac{E(t)}{\varDelta _{t} } < P_{load}(t) \end{aligned}$$(2)$$\begin{aligned} P_{grid}(t)= P_{load}(t)-\left( P_{pv}^{t}(t)+ P_{wt}^{t}(t) + \frac{E(t)}{\varDelta _{t} }\right) \end{aligned}$$(3)In this case, the main grid will inject the required power noted \(P_{grid}(t)\) to balance the energy inside the microgrid by covering all the needed power.

-

The third scenario occurs when the following relationship is verified:

$$\begin{aligned} P_{pv}^{t}(t)+ P_{wt}^{t}(t) + \frac{E(t)}{\varDelta _{t} } > P_{load}(t) \end{aligned}$$(4)In this case, the microgrid will inject extra power into the main grid.

In this study, the power converters are considered to work in ideal conditions, which means that it will not take into account the losses provided; however, the converters are presented by their theoretical efficiency in the technical study, and they are not subject to optimization. The characteristics of the components for the microgrid presented in this study are described in Table 2.

5 Problem Formulation

The problem of optimal sizing the microgrid system is formulated as a multi-objective optimization approach, taking into account two cost functions characterizing the economical and environmental criteria, respectively, subjected to constraints that are defined to satisfy the correct microgrid operation.

5.1 Objective Functions

Objective 1: Installation Cost Minimization. The economic criteria, including the system’s component purchase price, maintenance expenses, and component replacement prices, are taken into account by the economic objective function. The objective function aims to satisfy the necessary technical constraints while getting the ideal number of microgrid components. For a system lifespan of T equal to 20 years, the microgrid system cost, in euros, is provided by [8]:

where, \(N_{pv}\), \(N_{wt}\), \(N_{b}\) are, respectively, the number of units of photovoltaic modules, wind turbines and batteries, \(C_{pv}\), \(C_{wt}\), \(C_{b}\), \(C_{die}\), \(C_{conv}\) are respectively the purchase costs of renewable units (photovoltaic and wind), battery unit, diesel group and overall converters, \(M_{pv}\), \(M_{wt}\), \(M_{b}\) are the maintenance costs for the renewable energy systems (photovoltaic and wind systems) and also battery bank. Finally, \(K_{pv}\), \(K_{wt}\), \(K_{b}\) are, respectively, the number of equipment replacements during the system lifetime.

The optimization model for microgrid installation cost can be written as follow:

The optimization model will lead to finding \(N_{pv}\), \(N_{wt}\), and \(N_{b}\), i.e., the optimum set points that define the optimal number of microgrid components: wind turbines, photovoltaics, and batteries, at the lowest price while respecting the constraint that will be defined in the rest of the paper.

Objective 2: Environmental Function. Nitrous oxide (\(N_{2}O\)), carbon dioxide (\(CO_{2}\)), and methane (\(CH_{4}\)) are the main components of GHG emissions. In most cases, carbon dioxide (\(CO_{2}\)), or its equivalent (\(CO_{2}eq\)), is used as the measurement unit for GHG emissions. The overall carbon footprint estimation for the microgrid system set-up represents the emissions released during its manufacturing process [17]. However, the total (\(CO_{2}eq\)) emission function is given as follows:

where, \(GHG_{PV}^{CO2eq}\), \(GHG_{WT}^{CO2eq}\), \(GHG_{b}^{CO2eq}\) are, respectively, the GHG emissions of the photovoltaic, wind turbine, and battery released during the manufacturing process of the units represented on carbon dioxide (\(CO_{2}\)) and expressed on (\(CO_{2eq}\)).

where, \(S_{pv}\) is the photovoltaic surface panel, \( S_{WT}\) is the swept area by the blades of the wind turbine, and \(C^{n}\) is battery nominal capacity [17].

The optimization model for the microgrid environmental model can be written as follows:

5.2 Constraints

Power Balance Constraint. The total amount of power generated must be sufficient to meet the overall demand (including storage) and transmission losses. In terms of frequency stability, the active power balance is a requirement for steady operation. Since the transmission losses are thought to be numerically insignificant, they are neglected in this work. The power balance’s state takes on the following form:

being \(P_{load}(t) \), the total electrical load demand at hour t. Moreover, the power of the energy storage system \(P_{b}(t)\) can be positive in the case of discharging or negative in the case of charging, and \(P_{pv} (t)\) and \(P_{pv} (t)\) are the power delivered by the photovoltaic and wind turbine generators at hour t.

Limit Generators Number Constraint. The limited number of generators in terms of setup surface must be considered during the optimization procedure as follows:

where, \(N_{pv}^{max}\), \(N_{pv}^{max}\) and \(N_{pv}^{max}\) is the maximal permitted numbers of photovoltaic, wind turbines, and batteries, respectively, to be installed.

6 Methodology

In this paper, two multiobjective optimization methods are used to define the optimal configuration of the microgrid: the Non-dominated Sorting Genetic Algorithm II (NSGA-II) and the Pareto Search algorithm. The results will be presented on a set of Pareto fronts, including the non-dominated points that reflect the scenarios proposed by the optimization process according to the constraints defined above, to ensure technical satisfaction for the secure and reliable operation of the microgrid system. Given the clustering of the non-dominated points using the k-means approach, an informed choice of scenarios will be determined. On the reverse side, the effectiveness of scenarios will be investigated through the microgrid operating system’s behavior. However, the proposed microgrid system can operate both in isolated mode and/or grid-connected mode. The power distribution approach is simplified into the following situations:

-

1.

The power generated by renewable sources must meet the load demand in order for the system to operate safely. Additionally, excessive amounts of power produced by renewable resources require that batteries be charged first before any extra power is put onto the main grid.

-

2.

Renewable energy sources cannot produce enough power to fulfill demand; an energy storage system will satisfy the shortage. In the event that this latter is insufficient, the main network compensates for the energy imbalance.

-

3.

The electricity produced by the diesel group is regarded as the last resort and a highly polluting source that will only be used in the event of a complete blackout within the main grid.

7 Results and Discussions

This section presents the results of the optimization strategies. After the optimal number of units is reached, a technical study is done to evaluate the installation’s dependability given the number of microgrid units. Additionally, a lifetime cost estimate of the system is given, taking into account every scenario that has been suggested. The optimization problem and microgrid operation were programmed and simulated using the MATLAB programming language.

7.1 Optimization Results and Scenarios Identification

The study’s microgrid sizing problem has been solved using two multi-objective optimization techniques, NSGA-II and Pareto search algorithms. The Pareto front of non-dominated points is displayed in Fig. 3.

A cluster evaluation using the “silhouette” approach has been carried out in order to determine scenarios that exist in accordance with the optimization results achieved. The silhouette plot reveals that the data are separated into three clusters. Each of the three clusters has a substantial silhouette value determined by the Euclidean distance metric, as illustrated in Fig. 4.

The clustering has been performed using the k-means approach with (\(k=3\)), the results are presented in Fig. 5.

According to the clusters, three sets of scenarios can be identified, including the best economic scenarios (Cluster 03), best environmental scenarios (Cluster 02), and traded-off scenarios (Cluster 01). The distinct scenario that represents each cluster has been chosen from the extreme of each recognized set of situations, except for the trade-off case, in which the centroid has been selected as a cluster-representative scenario. Table 3 displays the microgrid sizing scenarios that were selected based on the previously addressed device characteristics.

The optimal configurations illustrate three microgrids from different perspectives. However, the first scenario takes into consideration adopting a combination of elements that gives an optimal installation cost; the outcomes of this case were similar compared to the results obtained in [8], in which installation cost minimization was the objective of the study. The second scenario represents a balance between the two criteria, economic and environmental, respectively. The third scenario gives priority to installing sources that emit less \(CO_{2}\) during their manufacturing process. According to Sect. 5.1, it can be noted that the batteries are the least emissive, which justifies the high number of these devices employed in this scenario.

7.2 Scenarios Technical Evaluation

The effectiveness of the scenario has been evaluated using a 24-hour operation analysis of each microgrid configuration.

Best Economical Scenario. In this case, the microgrid was established via 50 photovoltaic panels, 3 wind turbines, and an energy storage system consisting of 13 batteries, along with the diesel group and connection to the main grid. As shown in Fig. 6b by a 24-hour operation taking into account the presence of all RE sources, it can be seen that under these circumstances, the microgrid is capable of operating in a stable condition in which the load is continuously fed and the excess energy has been used to charge the energy storage system during peak production, when the set of batteries reached nearly the \(SOC_{max}\) as Fig. 6a illustrate.

Furthermore, the microgrid was able to feed the user continuously for 24 h in the absence of all RES, reaching \(SOC_{min}\) in the last hours of the day, as illustrated in Fig. 7a.

Trade-Off Scenario. This setup consists of 55 photovoltaic panels, 2 wind turbines, 7 batteries, and a diesel generator that serves as a backup system in the event of a microgrid failure or a main grid blackout. As seen in Fig. 8a the batteries were able to feed the microgrid at night in normal operation. The microgrid users were able to meet their energy needs during the day owing to the photovoltaic park and the wind turbine. In addition, the battery was fully charged at 16 o’clock, when both the wind and the sun’s potential were still present, and the excess energy was injected into the main grid between 17 o’clock and 20 o’clock, as shown in Fig. 8b. Practically, the microgrid was producing more energy than was required to supply the load while simultaneously charging the energy storage system to its fullest capacity.

In the absence of all renewable energy sources, the batteries fed the microgrid up to the point of minimal charge before feeding the consumer directly from the main network, ensuring that the system’s dependability is maintained and the user’s comfort is unaffected by the microgrid’s power shortage, as illustrated in Fig. 9.

Best Environmental Scenario. In this instance, the diesel group and the main grid were connected to the microgrid, which included 46 photovoltaic panels, 1 wind turbine, and a system of 44 batteries for energy storage. An abusive number of batteries made the microgrid able to work permanently even in the absence of all renewable features As presented in Fig. 11a. This case brings a very high cost of installation that will not ensure the gain on the investment during the lifetime of the installation (\(T=20\) years) mainly because the batteries have to be changed every 4 years as required to ensure their reliability inside the microgrid system. This set of changes will undoubtedly bring a huge cost of replacement.

Without ignoring the duration of charging and the high energy flow that must be fully supplied for reaching the \(SOC_{max}\) of the energy storage system, the microgrid’s local energy sources are insufficient, necessitating an assortment of energy compensations from the main grid.

8 Conclusions and Future Work

This study is a continuation of [8] and focuses on the sizing and optimization of an AC/DC microgrid composed of a set of distributed generators, including a park of photovoltaic panels, a wind turbine farm, and a set of electrochemical batteries. The microgrid is connected to the main grid through a common coupling point (PCC). A diesel generator has been used as a backup system in the event of a microgrid failure or main grid blackout. A data set of solar potential, wind speed, and temperature has been analyzed. Two multi-objective optimization algorithms have been used to solve the problem, including the Non-dominated Sorting Genetic Algorithm (NSGA II) and the Pareto Search (PS) algorithm. The results delivered a Pareto front of non-dominated points consisting of two objectives: total installation cost, and total GHG emissions. Three groups of scenarios have been identified by clustering the points of the Pareto front using the k-means method: economic, environmental, and traded-off. The best scenarios for each cluster are analyzed in 24-hour microgrid operation to identify its reliability.

In the future, the authors will extend this paper by including a third objective function representing embodied energy (EE), which represents the quantity of non-renewable energy consumed during the life cycle of different elements of the microgrid with an economic analysis of the microgrid investment costs taking into account all potential outcomes. Additionally, the authors are studying the sizing of the system in a DC configuration.

References

Amoura, Y., Torres, S., Lima, J., Pereira, A.I.: Hybrid optimisation and machine learning models for wind and solar data prediction. Int. J. Hybrid Intell. Syst. 19(7875), 1–16 (2023). https://doi.org/10.3233/his-230004

Christopher, S.: Renewable energy potential towards attainment of net-zero energy buildings status - a critical review. J. Clean. Prod. 405, 136942 (2023). https://doi.org/10.1016/j.jclepro.2023.136942

Tvaronavičienė, M.: Towards renewable energy: opportunities and challenges. Energies 16(5), 2269 (2023). https://doi.org/10.3390/en16052269

Li, C., Umair, M.: Does green finance development goals affects renewable energy in China. Renewable Energy 203, 898–905 (2023). https://doi.org/10.1016/j.renene.2022.12.066

Hossain, J., et al.: A review on optimal energy management in commercial buildings. Energies 16(4), 1609 (2023). https://doi.org/10.3390/en16041609

Statista Research Department. Global Microgrid Market Value 2017–2028. Statista (2023). https://www.statista.com/statistics/1313998/global-microgrid-market-size/. Accessed 29 Apr 2023

Mustafa Kamal, M., Ashraf, I.: Evaluation of a hybrid power system based on renewable and energy storage for reliable rural electrification. Renewable Energy Focus 45, 179–191 (2023). https://doi.org/10.1016/j.ref.2023.04.002

Amoura, Y., Ferreira, Â.P., Lima, J., Pereira, A.I.: Optimal sizing of a hybrid energy system based on renewable energy using evolutionary optimization algorithms. In: Pereira, A.I., et al. (eds.) OL2A 2021. CCIS, vol. 1488, pp. 153–168. Springer, Cham (2021). https://doi.org/10.1007/978-3-030-91885-9_12

Amoura, Y., Pereira, A.I., Lima, J.: Optimization methods for energy management in a microgrid system considering wind uncertainty data. In: Kumar, S., Purohit, S.D., Hiranwal, S., Prasad, M. (eds.) Proceedings of International Conference on Communication and Computational Technologies. AIS, pp. 117–141. Springer, Singapore (2021). https://doi.org/10.1007/978-981-16-3246-4_10

Zhang, J., Cho, H., Mago, P.J., Zhang, H., Yang, F.: Multi-objective particle swarm optimization (MOPSO) for a distributed energy system integrated with energy storage. J. Therm. Sci. 28(6), 1221–1235 (2019). https://doi.org/10.1007/s11630-019-1133-5

Sellami, R., Sher, F., Neji, R.: An improved MOPSO algorithm for optimal sizing amp; placement of distributed generation: a case study of the Tunisian offshore distribution network (ASHTART). Energy Rep. 8, 6960–6975 (2022). https://doi.org/10.1016/j.egyr.2022.05.049

Yusuf, A., Bayhan, N., Tiryaki, H., Hamawandi, B., Toprak, M.S., Ballikaya, S.: Multi-objective optimization of concentrated photovoltaic-thermoelectric hybrid system via non-dominated sorting genetic algorithm (NSGA II). Energy Convers. Manage. 236, 114065 (2021). https://doi.org/10.1016/j.enconman.2021.114065

Bora, T.C., Mariani, V.C., dos Santos Coelho, L.: Multi-objective optimization of the environmental-economic dispatch with reinforcement learning based on non-dominated sorting genetic algorithm. Appl. Therm. Eng. 146, 688–700 (2019). https://doi.org/10.1016/j.applthermaleng.2018.10.020

Fathima, A.H., Palanisamy, K.: Optimization in microgrids with hybrid energy systems - a review. Renew. Sustain. Energy Rev. 45, 431–446 (2015). https://doi.org/10.1016/j.rser.2015.01.059

Singh, P., Pandit, M., Srivastava, L.: Multi-objective optimal sizing of hybrid micro-grid system using an integrated intelligent technique. Energy 269, 126756 (2023). https://doi.org/10.1016/j.energy.2023.126756

Zhu, W., Guo, J., Zhao, G.: Multi-objective sizing optimization of hybrid renewable energy microgrid in a stand-alone marine context. Electronics 10(2), 174 (2021). https://doi.org/10.3390/electronics10020174

Khlifi, F., Cherif, H., Belhadj, J.: Environmental and economic optimization and sizing of a micro-grid with battery storage for an industrial application. Energies 14(18), 5913 (2021). https://doi.org/10.3390/en14185913

Deb, K., Pratap, A., Agarwal, S., Meyarivan, T.: A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 6(2), 182–197 (2002). https://doi.org/10.1109/4235.996017

Acknowledgements

This work has been supported by FCT - Fundação para a Ciência e Tecnologia within the R &D Units Project Scope: UIDB/05757/2020, UIDP/05757/2020.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2024 The Author(s)

About this paper

Cite this paper

Amoura, Y., Pedroso, A., Ferreira, Â., Lima, J., Torres, S., Pereira, A.I. (2024). Multi-objective Optimal Sizing of an AC/DC Grid Connected Microgrid System. In: Pereira, A.I., Mendes, A., Fernandes, F.P., Pacheco, M.F., Coelho, J.P., Lima, J. (eds) Optimization, Learning Algorithms and Applications. OL2A 2023. Communications in Computer and Information Science, vol 1982 . Springer, Cham. https://doi.org/10.1007/978-3-031-53036-4_23

Download citation

DOI: https://doi.org/10.1007/978-3-031-53036-4_23

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-53035-7

Online ISBN: 978-3-031-53036-4

eBook Packages: Computer ScienceComputer Science (R0)