Abstract

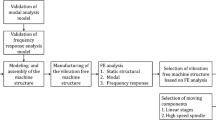

Ultrasonic vibration-assisted machining (UVAM) is one of the most promising innovations in high precision machining of advanced materials such as titanium alloys for aerospace applications or silicon carbide materials for the semiconductor industry. UVAM improves the process efficiency by increasing tool life through lower cutting forces and temperatures. However, in vibration-assisted milling applications, it is necessary to isolate the spindle system from the vibrations induced by the oscillation actor in order to maintain the long-term accuracy of the machine. This paper presents an innovative approach based on the integration of high damping materials into the toolholder to improve its damping capacity while maintaining the necessary stiffness. Therefore, the tool holder was developed with cylindrical damping inserts in a radial pattern with shrink fit connections. According to the results it was shown that the damping capability of a conventional toolholder can be improved without unacceptably reducing its radial stiffness compared to a standard toolholder geometry.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Zhang, C., et al.: An investigation of the high-frequency ultrasonic vibration-assisted cutting of steel optical moulds. MDPI Micromachines 12, 460 (2021)

Bulla, B.: Ultrapräzisionszerspanung von Nanokorn-Hartmetall mit Monokristallinen Diamantwerkzeugen. Apprimus Verlag, Aachen (2013)

Abele, E., Altintas, Y., Brecher, C.: Machine tool spindle units. CIRP Ann. Manuf. Technol. 59, 781–802 (2010)

Homepage SMB Bearings. https://www.smbbearings.com/technical/bearing-noise-vibration.html. Accessed 21 Aug 2023

Lee, H.W., et al.: Modelling ultrasonic vibration fatigue with unified mechanics theory. Int. J. Solids Struct. 236–237 (2022)

Möhring, H.-C., et al.: Materials in machine tool structures. CIRP Ann. Manuf. Technol. 64, 725–748 (2015)

Jehring, U.: Schwingungsdämpfung mit partikelgefüllten Hohlkugeln. Technische Universität Dresden, Dresden (2019)

Vogel, F.A.M., et al.: Vibration supressing in turning TiAl6V4 using additively manufactured tool holders with special structured, particle filled hollow elements. In: 19th Machining Innovations Conference for Aerospace Industry, pp. 32–37. Elsevier, Amsterdam (2019)

Teige, C.: Entwicklung gedämpfter Werkzeugaufnahmen für lang auskragende rotierende Werkzeuge. In: Institut für Fertigungstechnik und Werkzeugmaschinen Leibnitz Universität Hannover, Hannover (2018)

Baur, M.: Aktives Dämpfungssystem zur Ratterunterdrückung an Spanenden Werkzeugmaschinen. Technische Universität München, München (2014)

Werkle, K.T., et al.: Additively manufactured, particle-filled damping structures with magnetorheological fluids. In: 54th CIPP Conference on Manufacturing Systems, pp. 1418–1423. Elsevier, Amsterdam (2021)

Kollmann, F.G.: Praktische Maschinenakustik. Springer, Heidelberg (2005)

Cremer, L., Heckl, M.: Körperschall, 3rd edn. Springer, Heidelberg (2010)

Beards, C.F.: Structural Vibration: Analysis and Damping. Butterworth-Heinemann, Oxford (1996)

Grothe, K.-H., Feldhusen, J.: Dubbel-Taschenbuch für den Maschinenbau, 22nd edn. Springer, Heidelberg (2007)

Lazan, B.J.: Damping of Materials and Members in Structural Mechanics. Pergamon Press, Oxford (1968)

Ilschner, B., Singer, R.F.: Werkstoffwissenschaften und Fertigungstechnik, 4th edn. Springer, Heidelberg (2005)

Hildebrand, M., Adams, R.D.: Vibration damping. In: Adhesive Bonding, 2nd edn. Woodhead Publishing, Sawston (2021)

Niehus, K.K.: Identifikation Linearer Dämpfungsmodelle für Werkzeugmaschinenstrukturen. Technische Universität München, München (2015)

Acknowledgements

This work is supported by the funding program Zentrales Innovationsprogramm Mittelstand (ZIM) by the Federal Ministry for Economic Affairs and Climate Action (BMWK), Berlin, Germany.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Tschöpel, J., Hocke, T., Polte, M., Fleiner, B., Dicke, C., Uhlmann, E. (2024). Development of a Damped Toolholder for Vibration-Assisted High-Precision Milling Using High Damping Metals. In: Bauernhansl, T., Verl, A., Liewald, M., Möhring, HC. (eds) Production at the Leading Edge of Technology. WGP 2023. Lecture Notes in Production Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-47394-4_37

Download citation

DOI: https://doi.org/10.1007/978-3-031-47394-4_37

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-47393-7

Online ISBN: 978-3-031-47394-4

eBook Packages: EngineeringEngineering (R0)