Abstract

The tubular metal constructions find their applications in the following industrial sectors: metal tanks, industrial hangars, metal bridges, commercial buildings, pipelines, support for oil platforms etc. The phenomenon of stress concentration, born in the welded zones, contributes to the damage of these structure.

In the literature, the semi-parametric formulas give information about the stress concentration factor value, but gives no idea about its distribution.

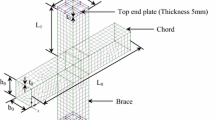

In this study, three different Y-joints have been studied. A finite element modeling was used to show the inclination brace effect (θ = 45°, θ = 60° and θ = 90°) on the distribution of stress concentration factor SCF and on the tubular Y-joint strength under deflected bending loads.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Chen, Y., Yang, J., Hu, K.: Parametric study and formulae of SCFs for positive large eccentricity CHS N-joints. J. Constr. Steel Res. 120, 117–131 (2016). https://doi.org/10.1016/j.jcsr.2016.01.005

Shao, Y.-B., Du, Z.-F., Lie, S.-T.: Prediction of hot spot stress distribution for tubular K-joints under basic loadings. J. Constr. Steel Res. 65(10), 2011–2026 (2009). https://doi.org/10.1016/j.jcsr.2009.05.004

Gao, F., Shao, Y.B., Gho, W.M.: Stress and strain concentration factors of completely overlapped tubular joints under lap brace IPB load. J. Constr. Steel Res. 63(3), 305–316 (2007). https://doi.org/10.1016/j.jcsr.2006.05.007

Yang, J., Chen, Y., Hu, K.: Stress concentration factors of negative large eccentricity tubular N-joints under axial compressive loading in vertical brace. Thin-Walled Struct. 96, 359–371 (2015). https://doi.org/10.1016/j.tws.2015.08.027

Liu, G., Zhao, X., Huang, Y.: Prediction of stress distribution along the intersection of tubular T-joints by a novel structural stress approach. Int. J. Fatigue 80, 216–230 (2015). https://doi.org/10.1016/j.ijfatigue.2015.05.021

Chiew, S.P., Soh, C.K., Wu, N.W.: General SCF design equations for steel multiplanar tubular XX-joints. Int. J. Fatigue 22(4), 283–293 (2000). https://doi.org/10.1016/S0142-1123(99)00130-9

Karamanos, S.A., Romeijn, A., Wardenier, J.: Stress concentrations in multi-planar welded CHS XX-connections. J. Constr. Steel Res. 50(3), 259–282 (1999). https://doi.org/10.1016/S0143-974X(98)00244-2

Woghiren, C.O., Brennan, F.P.: Weld toe stress concentrations in multi-planar stiffened tubular KK joints. Int. J. Fatigue 31(1), 164–172 (2009). https://doi.org/10.1016/j.ijfatigue.2008.03.039

Chang, E., Dover, W.D.: Parametric equations to predict stress distributions along the intersection of tubular X and DT-joints. Int. J. Fatigue 21(6), 619–635 (1999). https://doi.org/10.1016/S0142-1123(99)00018-3

Hamed, A.F., Khalid, Y.A., Sahari, B.B., Hamdan, M.M.: Finite element and experimental analysis for the effect of elliptical chord shape on tubular T-joint strength. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 215(2), 123–131 (2001). https://doi.org/10.1243/0954408011530370

Hobbacher, A., I. I. of Welding. Joint Working Group XIII-XV. Fatigue Design of Welded Joints and Components: Recommendations of IIW Joint Working Group XIII-XV, XIII-1539–96/XV-845–96. Abington (1996)

Welded tubular joints (1987 edition) | Open Library. https://openlibrary.org/works/OL18922254W/Welded_tubular_joints

Acknowledgements

The experimental tests were carried out under the direction of Pr S.E. Jalal, Z. El Maskaoui, A. Chouaf at the Laboratory of Mechanics, Engineering and Innovation, Higher School of Electricity and Mechanics ENSEM, Hassan II University, Casablanca Morocco. The authors gratefully acknowledge the anonymous reviewers of this preliminary version of this article.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Chouha, E., Jalal, S., Maskaoui, Z.E., Chouaf, A. (2024). Numerical Study of the Effect of the Brace Inclination on the Stress Concentration Factor for Three Different Welded Tubular Y-Joints Subjected to Deflected Bending Load. In: Aniss, S., et al. Advances in Mechanics. CMM 2022. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-46973-2_3

Download citation

DOI: https://doi.org/10.1007/978-3-031-46973-2_3

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-46972-5

Online ISBN: 978-3-031-46973-2

eBook Packages: EngineeringEngineering (R0)