Abstract

The mining sector is the largest solid waste producer in the world. Mining, mineral processing, and metallurgical activities generate more than 100 billion tons of waste per year in several forms. However, the current management of mine waste is still based on a linear system through its storage and landfilling. At the same time, growth of urbanization and industrialization induces the consumption of natural resources for building engineering in many countries. In this regard, the high demand for raw materials in the construction industry is becoming a worldwide issue. In order to tackle those challenges presented by the mining sector and the depletion of natural resources, innovative concepts are being developed. The circular economy concept is very beneficial, where mine waste can be considered as new raw materials for other applications, which will contribute not only to the reduction of natural resource consumption but also to the reduction of CO2 emissions. This chapter sheds light on the implementation of the circular economy concept with regard to the impact toward sustainable development goals, supported by examples of actual experiences around the world. Moreover, the importance of technical advances and the legislative aspect is discussed in order to underline its contribution to sustainable development.

You have full access to this open access chapter, Download chapter PDF

Similar content being viewed by others

Keywords

4.1 Introduction

For the past 150 years, the one-sense model of production and consumption has dominated the world. In this concept of a one-way supply chain, commodities undergo industrial processes to transform raw materials into finished products that are sold, utilized, and eventually disposed of either by incineration or as waste when they reach the end of their useful life. The raw materials that were initially gathered from nature are typically thrown away after a certain product has been consumed. This model is sometimes referred to as a linear model because it simply follows a linear route. It is more obvious that a linear business model cannot be continued for sustainable development due to the increasing growth in population, urbanization, and industrialization. Thus, growing demands for resource consumption lead to negative environmental impacts. However, policymakers, scholars, global corporations, and implementers are more interested in the move from the current linear economic model to a circular one.

The Ellen MacArthur Foundation (EMF) released research at the World Economic Forum in 2012 that assesses the possible advantages of the shift to a circular economy (CE). Only a portion of the EU industrial sectors might potentially benefit from approximately US$630 billion annually [1]. CE has considerable environmental and social benefits in addition to its enormous economic advantages, according to the EMF. To minimize resource leakage, CE is able to separate economic growth from the use of resources. This can be done through the share, lease, reuse, repair, renovate, and recycle in a closed loop.

Contemporary society cannot function without metals. The demand for raw resources has expanded globally in recent decades, and between 2010 and 2030, resource utilization is predicted to even double [2]. The UN sustainable development objectives and the execution of the Paris Agreement adopted in 2015 led to the extensive use of a diversity of minerals for low-carbon applications.

As stated in Principle 8 of the International Council on Mining and Metals principles (ICMM), mining operations are linked to the use and disposal of goods that contain metals, involving the mining sector in efforts to close material cycles through recycling on a global scale. However, it is important to investigate potential at the mining site level before expanding the extractive industry’s accountability across the full value chain. Otherwise, the construction sector is an important pillar of modern civilization. However, it has a negative environmental effect but contributes to environmental protection through the concept of sustainable construction [3]. Traditional construction gives little consideration to the effects on the environment and instead prioritizes cost, time, and quality. Nevertheless, sustainable construction tends to social demands while taking precautions to reduce any potentially harmful effects on the environment. Adopting sustainable construction practices can effectively lower the negative effects of construction activities.

It is very important to find adequate ways to reach the desired economic growth without negatively impacting the environment. This is only possible through the CE concept implementations in different sectors, and in diverse cycles (upcycle, downcycle). This strategy is a big enabler for both the mining and construction sectors to thrive through sustainability. In this chapter, the impact of the implementation of CE is discussed between the mining and construction industries. Case studies from several countries and companies are used as examples to provide a better vision. Moreover, multiple technical advances and future perspectives are presented to give more insight.

4.2 Mine Waste Management and Environmental Issues

4.2.1 Mining Industry and Waste Generation

The mining sector is an essential aspect in economic growth by providing vital raw materials and energy for many industries. However, its activities are still considered an impediment to natural resources, with negative environmental effects. In this context, the last decade has seen a renewed discussion about mining and sustainability due to public worries about the current degradation of the environment related to diverse mining processes.

Mine waste is the largest waste flow in the EU. Each year, mining activities produce huge quantities of mine waste. As stated by the Mining, Minerals, and Sustainable Development Project, about 3500 mineral waste facilities are active worldwide, composed mainly of dumps and dams. Over 100 billion tons of solid waste are produced annually from mining around the world presenting major environmental issues needing adequate management strategies [4].

The global estimated amount of waste from metal mining generated is approximately 4 gigatons/year [5]. At the same time over 1.2 billion tons of residue waste have previously been produced in the EU [6]. The valorization of mine waste is encouraged due to the financial and environmental expenses related to its management. In addition, these residues are considered raw materials in other technologies such as construction and buildings.

4.2.2 Environmental Risks Related to Mine Waste

Mining waste management involves the identification of diverse wastes and their effects on the environment and society in the framework of mining waste mitigation. The environmental risks of mining waste generation are acidity formation, heavy metals leaching, and stability of the tailings. Tailing dam catastrophes have happened in several countries. A dam is a storage space occupying several square kilometers of land, that could suffer from failures, responsible for environmental disasters. In 2008 when a dam accident happened in China 277 people died [7]. Tailings dam collapsed in 2015 in Brazil leading to the release of about 43.7 million m2 of residues. In 2019, an iron tailings dam in Vale collapsed resulting in the death of 206 people [8]. Furthermore, waste rock and tailings cause severe human health complications resulting from the release of pollutants by leakage. Acid mine drainage (AMD) is a significant issue in mining activities. AMD is produced by sulfide oxidation in wastes releasing high content of sulfate, iron, and heavy metals characterized by acidic pH. AMD negatively impacts groundwater quality and limits the use of downstream water. The rehabilitation policies and the design of water treatment facilities remain important solutions to protect the surrounding environment. The remediation of AMD is still costly at around US$1.5 billion per year and the global environmental responsibilities are more than US$100 billion [9].

Different disposal methods of tailings are studied including conventional disposal; tailings reuse, recycling, reprocessing; and proactive management respecting the ICMM principle 8 (Table 4.1). The important statement is adopting an integrative approach for tailings management to improve environmental, social, and economic results. Thus, the recycling and reuse of mine tailings are new technologies to remediate environmental issues.

4.3 Valorization of Mine Waste for Construction Applications

4.3.1 Recycling of Mining Solid Waste for Construction Materials

In the framework of sustainable development goals (SDGs) of the UN and the implementation of the Paris Agreement, diverse minerals are used for green technologies considering low-carbon applications. The recycling of mine waste is quite compatible with the UN’s SDGs. Mine tailing valorization participates notably in SDG11 “Sustainable Cities and Communities” and to SDG12 “Responsible Consumption and Production” by minimizing the output of waste. The management of mining waste currently consists of linear system thinking “take-make-waste.” The employment of a CE model in the mining sector is necessary to resolve the issues of environmental pollution and to minimize waste with the generation of economic profits.

In another context, urbanization critically increases as 55% of the population lives in urban areas and will rise to 68% by 2050 implying a great consumption of raw materials to design building products [10]. To minimize this negative impact, the European Commission aimed to decrease the emissions related to the construction industry by 90% in 2050 [11]. Thus, the employment of residues to replace raw materials in construction may be an efficient method to attain CE goals by producing eco-friendly building materials with low embodied energy.

Mine wastes are considered a sustainable source of alternative materials in construction applications. These wastes are valorized as raw materials to produce clinker, bricks, aggregates, mortar, concrete, and geopolymers. The evaluation of the use of mine wastes and tailings as cementitious materials has roughly been investigated. Coal waste was used as raw material to produce clinker encouraging the saving of fossil fuels in kiln combustion [12]. Ceramics applications present an important alternative to reduce the costs associated with the management of mine tailings. In Russia, wastes from coal mines were recycled to produce ceramic bricks [13]. The fired bricks application is mainly targeted to allow the immobilization of the pollutant elements in the ceramic matrix [14].

Xu et al. [15] investigated the substitution of natural aggregates by iron tailings fine and coarse aggregates to produce concrete. Fontes et al. [16] used these tailings to produce ceramic tiles. Lam et al. [17] employed copper tailings as fine aggregates to elaborate concrete paving stones. More recently, Huynh et al. [18] tested the performance of fine-grained concrete samples using copper tailings. In addition, phosphate mine waste was recycled as coarse aggregates in concrete [19, 20]. Furthermore, Sedira et al. [21] recycled tungsten waste mud in alkali-activated binder. Furthermore, metallic tailings containing lead and zinc were valorized as aggregates for the formulation of mortar [22]. Mining waste from copper, gold, iron, bauxite, vanadium, zinc, and phosphate ores was used in the production of geopolymers for construction applications [23].

4.3.2 CE Concept Implementation in Mining Sector

The most recent approach to improving environmental sustainability is CE. Although Leontief [24] initially discussed CE in 1928, its first international application came when the German Parliament established a law on CE in 1996 [25]. Since the end of the 1990s, CE has been launched in China to solve environmental issues [26]. The visual representation of the CE concept is presented in Fig. 4.1. There is strong interest in CE in the political agenda in Europe to promote economic growth while reducing environmental impacts. In the UK, the implementation of a CE could produce 50,000 new jobs and attract investment of up to €12 billion [27]. The minerals and mining sector has made significant progress in the performance assessment of CE in relation to sustainable development, and the construction and building sector has also received substantial attention. Introducing a CE model into the mining sector could transform the industry into a sustainable one. Furthermore, the mining industry has enormous potential to adopt the CE approach by utilizing waste materials at different life cycle stages and developing eco-friendly products. Despite being in the early stages of the CE implementation, the development and implications of CE in the mining sector have grown significantly in recent years. The current CE agenda focuses on the supply chain of materials and the recovery of waste for direct reuse, which are two critical principles for a successful CE implementation.

The implementation of CE in the mining and construction/building sectors can significantly contribute to achieving the Sustainable Development Goal (SDG12), responsible consumption and production. By adopting a CE approach, these sectors can reduce waste and resource consumption while promoting resource efficiency and closed-loop systems. This can be achieved by recycling materials and products, using renewable energy sources, and improving product design to extend their lifespan. In the mining sector, the use of waste materials as a source of secondary raw materials can reduce the need for extracting new materials from the earth, thus minimizing the environmental impact of mining operations. Similarly in construction, the use of recycled materials and prefabricated modular construction can minimize waste and resource consumption, while reducing construction time and cost.

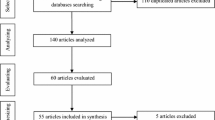

Moreover, the implementation of CE can have positive effects on multiple SDGs. For instance, the use of renewable energy sources in mining and construction can contribute to achieving SDG7, affordable and clean energy. The development of closed-loop systems and resource-efficient technologies can promote SDG9, industry, innovation, and infrastructure, and SDG11, sustainable cities and communities, by reducing the environmental impact of industrial activities and improving the sustainability of urban areas. The reduction of water consumption and the treatment of wastewater can contribute to achieving SDG6, clean water, and sanitation, while the promotion of decent work and the creation of green jobs can promote SDG8, decent work, and economic growth. The reduction of greenhouse gas emissions and the adoption of sustainable land management practices can contribute to achieving SDG13, climate action, and SDG15, life on land, by mitigating the impact of industrial activities on the environment and preserving biodiversity. Figure 4.2 provides the percentage of addressed SDGs by projects related to the implementation of CE on the reuse of mine waste in the construction sector. A summary of the implementation status of CE in different countries shows that a global urge for such policy exists and some countries have reached a developed stage of implementation, while others remain at the beginning, as illustrated in Fig. 4.3. This fact is linked to many factors, the existence of laws, financial support and socio-economic awareness of the positive impact of adopting CE. The countries indicated in Fig. 4.3 are classified into four categories regarding their implementation of CE. Germany, Norway, South Korea, and the UK have advanced CE-driven societies and have attained a substantially greater level of the CE implementation. Australia, Canada, China, and the United States are in a less advanced state. Either they started the CE process more recently with significant implementation outcomes, or they started the CE process years ago with little success. Fewer countries, including Bhutan and Vietnam, have pioneered CE-driven societies through a number of actions and measures. In many areas of the economy, they began to minimize and reuse resources, and they saw progress. Afghanistan, Israel, and Morocco are at the beginning stages of implementing CE concepts, while there are a few isolated instances when resource recycling occurs on individual initiatives.

Status of CE implementation in countries. (Data from [28])

CE practices such as reusing and recycling mining waste have been successful in reducing resource waste. Anglo-American, a mining company based in South Africa, has implemented a zero-waste-to-landfill strategy by repurposing or recycling mining waste. To reduce the amount of hazardous waste sent to landfills, they employ a bioremediation plant that restores soil affected by hydrocarbon spills, thus promoting health, and protecting life on land, which is in line with SDG15 and SDG3. Recycling post-consumer minerals and metals at the end of their life through mineral recovery can also give resources a new lease on life. For instance, Sumitomo Metal Mining was able to increase its copper scrap recovery rates significantly by processing high-purity copper scraps directly at their Tokyo smelter and refinery between 2010 and 2015. Lastly, by increasing comminution efficiency, energy recovery practices can recover the heat generated from mining processes and convert it into usable energy.

There are various global public policies that support circularity of minerals and metals. The CE Action Plan in Europe offers guidance and promotes best practices in mining waste management plans across the EU. The Canadian Minerals and Metals Plan emphasizes the continuous reduction of mining’s environmental footprint by promoting CE practices, including transforming mine waste into useful products, enhanced mine closure planning, and environmentally reclaimed mine sites. The plan also includes systemic climate change adaptation planning. The Green Mining Initiative aims to improve energy efficiency, enhance productivity, and improve waste management and water management. The initiative has two main objectives: to reduce the environmental impacts of mining and to enhance Canada’s competitiveness.

Mining in Australia has taken the lead in the development of CE in eco-industrial regions. Recently, regulatory strategies for metal recycling have been reevaluated based on the CE concept to revise regulations and their application to various stages of a metal’s lifecycle from extraction to disposal. In Finland, Sitra’s CE roadmap aims to reduce environmental impact, promote sustainable use of non-renewable resources, and utilize side streams. Mining waste including tailings, sludge, slag, dust, and ash can be considered secondary raw materials moving towards zero waste. In China, Urban Mining Pilot Cities aim to reduce the production of recyclable waste and promote sustainable urbanization. The CE model, consisting of “Reduce, Reuse, and Resource,” was tested in six classes of UMPCs across 49 cities between 2010 and 2015 to improve industrial development and resource utilization. Morocco’s mining industry holds 75% of the world’s phosphate reserves but generates large quantities of waste. To reduce waste and generate new income, the phosphate mining company is working on recycling phosphate by-products for construction applications using various technologies.

The adoption of this approach by countries is an important index, but in parallel, the implementation of CE can be very effective while included in companies’ business models and roadmaps. For instance, Boliden, a Swedish mining company, recovers metals from smelting slag and fly ash and turns them into construction materials. Canada-based Teck Resources recycles waste from its lead and zinc production to create new construction materials. Finnish start-up Betolar uses mining waste to create a low-carbon cement alternative, reducing carbon emissions from the cement industry.

Despite the progress made in implementing CE practices for mining waste reuse in the construction industry, there are still limitations and challenges that countries and companies face. One of the main challenges is the lack of standardization and certification for secondary raw materials. The quality and safety standards for these materials are not always clearly defined or consistent, which can create barriers to their use in construction. Another challenge is the transportation of mining waste to construction sites, which can result in increased greenhouse gas emissions and transportation costs. This issue can be mitigated by sourcing materials locally, but this may not always be possible. There are also financial challenges associated with implementing CE practices, as they may require upfront investment and long-term planning. Furthermore, regulatory frameworks and policies can vary greatly between countries and regions, which can create uncertainty for companies looking to implement CE practices. Finally, there may be social and cultural barriers to the adoption of CE practices, particularly in communities where mining has historically been a primary source of employment and economic development. It may take time and effort to build trust and support for new approaches to waste management and resource recovery.

4.3.3 Technical Advances and Future Perspectives

The reuse of mining waste in the construction industry is not a new concept. However, advances in technology have made it easier to transform these waste materials into useful products.

Advanced processing technologies including mechanical, thermal, and chemical processes are being used to transform mining waste into value-added products. These technologies are helping to develop new processes for transforming waste materials into valuable products and optimizing the design and construction of buildings using these materials. One example is the transformation of mining tailings into construction materials like lightweight aggregate, paving blocks, and bricks.

Geopolymer technology is a promising technique for the reuse of mining waste in the construction industry. This technique involves mining waste materials to produce geopolymer binders that could be used as a replacement for traditional cement in concrete production, reducing the environmental impact of cement production and providing a new market for mining waste materials.

Nanotechnology is being explored as a means of reusing mining waste materials in the construction industry. A process has been developed using nano-silica extracted from mining tailings to replace cement in concrete. This approach can improve the strength and durability of concrete while reducing its environmental impact.

The future perspectives for the implementation of CE to reuse mining wastes in the construction industry are promising. As the construction industry moves toward more sustainable practices, the reuse of mining waste materials can provide a valuable source of raw materials.

The integration of digital technologies like artificial intelligence, machine learning, and 3D printing is optimizing the reuse of mining waste materials in the construction industry. These technologies can help in developing new processes for transforming waste materials into valuable products and optimizing the design and construction of buildings using these materials. By doing so, the industry can make significant strides toward achieving sustainable and circular practices.

Circular business models are promising in promoting the reuse of mining waste materials in the construction industry. By creating new value chains for these materials, circular models create new revenue streams for the mining industry while reducing its environmental impact.

To assess the environmental impact of using mining waste materials in the construction industry, life cycle assessment (LCA) can be a useful tool. LCA can help identify the most sustainable use of these materials and optimize their use in the construction industry. LCA is also used to compare the environmental impact of using mining waste materials with that of traditional raw materials.

Material flow analysis (MFA) can assess the flows of materials within a system and identify opportunities for material reuse and recycling. MFA can be used to determine the sources and destinations of mining waste materials and optimize their use in the construction industry.

Blockchain technology can create a transparent and secure record of the provenance and quality of mining waste materials. This can increase their value and promote their reuse in the construction industry.

The Internet of Things (IoT) can also play a significant role in promoting the reuse of mining waste materials in the construction industry. By interconnecting physical devices and systems through the internet, IoT can enable data exchange and automation.

Digital twins are digital replicas of physical assets, systems, and processes. In the context of CE and mining waste reuse, digital twins can simulate and optimize construction processes, including the use of mining waste materials. By simulating the performance of construction materials made with mining waste under different environmental conditions, digital twins can identify optimal material formulations and manufacturing processes.

4.4 Conclusions

The world today faces environmental challenges growing over time and becoming an imminent threat to humankind. Industrialization is a huge step toward economic growth and well-being with a positive impact on humanity that cannot be neglected. But the negative impact on the environment should be emphasized at the same time. Thus, the need for a sort of agreement between the two is the only way to keep up the good part and tackle the problematic ones.

Mining operations generate significant amounts of waste. Their accumulation can cause dangerous environmental issues such as landslides, degradation of arable land, and acid mine drainage. Therefore, repurposing mining waste for practical purposes is crucial.

The construction industry is a major consumer of natural resources, causing significant environmental impact. An effective solution is to form partnerships between large waste rock producers and raw material consumers, which can reduce waste and raw material consumption while supporting economic growth and SDGs.

The CE implementation between those two big sectors is much more a need than a want today. This approach is the main directive to achieve the link between the above-mentioned environmental problems while giving room for the socio-economic thriving of businesses and countries. Accordingly, several countries are now starting their new way to achieving sustainability through the CE implementation. Technically, the CE implementation can only be done if the right techniques are involved. Therefore, LCA and other techniques are useful tools to assess the sustainability impacts of CE strategies.

Ultimately, this mixture of theoretical approaches and technical advances will never be possible to achieve without legal and administrative enabling. The urge in terms of administrative procedures and legislation is growing, and there should be a call to action in countries that are late in the CE implementation, after successful application experiences of the lead countries.

References

Ellen MacArthur Foundation. (2012). Towards the circular economy: Economic business rationale for an accelerated transition. Ellen MacArthur Foundation.

M. Reuter, C. Hudson, A. van Schaik, K. Heiskanen, C. Meskers, C. Hagelüken 2013 Metal recycling: Opportunities, limits, infrastructure.. A report of the working group on the global metal flows to the international resource panel.

Abidin, N. Z. (2009). Sustainable construction in Malaysia developers’ awareness. http://eprints.usm.my/15580/1/Sustainable_Construction_In_Malaysia-Developers_Awareness.pdf. Accessed 2 Jan 2023.

Lèbre, É., Corder, G. D., & Golev, A. (2017). Sustainable practices in the management of mining waste: A focus on the mineral resource. Minerals Engineering, 107, 34–42. https://doi.org/10.1016/J.MINENG.2016.12.004

Haas, W., Krausmann, F., Wiedenhofer, D., & Heinz, M. (2015). How circular is the global economy? An assessment of material flows, waste production, and recycling in the European Union and the world in 2005. Journal of Industrial Ecology, 19, 765–777. https://doi.org/10.1111/JIEC.12244

Wang, C., Harbottle, D., Liu, Q., & Xu, Z. (2014). Current state of fine mineral tailings treatment: A critical review on theory and practice. Minerals Engineering, 58, 113–131. https://doi.org/10.1016/J.MINENG.2014.01.018

Ke, X., Zhou, X., Wang, X., Wang, T., Hou, H., & Zhou, M. (2016). Effect of tailings fineness on the pore structure development of cemented paste backfill. Construction and Building Materials, 126, 345–350. https://doi.org/10.1016/J.CONBUILDMAT.2016.09.052

Tayebi-Khorami, M., Edraki, M., Corder, G., & Golev, A. (2019). Re-thinking mining waste through an integrative approach led by circular economy aspirations. Minerals, 9, 286–289. https://doi.org/10.3390/MIN9050286

Manchisi, J., & Ndlovu, S. (2021). Prediction of acid mine drainage formation. In Acid mine drainage (pp. 31–56). https://doi.org/10.1201/9780429401985-3

Desa, U. N. (2018). Revision of world urbanization prospects (p. 16). UN Department of Economic and Social Affairs.

Report to Congress: Wastes from the Extraction and Beneficiation of Metallic Ores, Phosphate Rock, Asbestos, Overburden from Uranium Mining and Oil Shale | US EPA. (n.d.). https://www.epa.gov/hw/report-congress-wastes-extraction-and-beneficiation-metallic-ores-phosphate-rock-asbestos. Accessed 20 Dec 2022.

Malagón, B., Fernández, G., de Luis, J. M., & Rodríguez, R. (2020). Feasibility study on the utilization of coal mining waste for Portland clinker production. Environmental Science and Pollution Research, 27, 21–32. https://doi.org/10.1007/S11356-019-05150-W/TABLES/11

Stolboushkin, A. Y., Ivanov, A. I., & Fomina, O. A. (2016). Use of coal-mining and processing wastes in production of bricks and fuel for their burning. Procedia Engineering, 150, 1496–1502. https://doi.org/10.1016/J.PROENG.2016.07.089

Taha, Y., Benzaazoua, M., Hakkou, R., & Mansori, M. (2017). Coal mine wastes recycling for coal recovery and eco-friendly bricks production. Minerals Engineering, 107, 123–138. https://doi.org/10.1016/j.mineng.2016.09.001

Xu, F., Wang, S., Li, T., Liu, B., Li, B., & Zhou, Y. (2021). Mechanical properties and pore structure of recycled aggregate concrete made with iron ore tailings and polypropylene fibers. Journal of Building Engineering, 33, 101572. https://doi.org/10.1016/J.JOBE.2020.101572

Fontes, W. C., Franco de Carvalho, J. M., Andrade, L. C. R., Segadães, A. M., & Peixoto, R. A. F. (2019). Assessment of the use potential of iron ore tailings in the manufacture of ceramic tiles: From tailings-dams to “brown porcelain”. Construction and Building Materials, 206, 111–121. https://doi.org/10.1016/J.CONBUILDMAT.2019.02.052

Lam, E. J., Zetola, V., Ramírez, Y., Montofré, Í. L., & Pereira, F. (2020). Making paving stones from copper mine tailings as aggregates. International Journal of Environmental Research and Public Health, 17, 2448. https://doi.org/10.3390/IJERPH17072448

Huynh, T. P., Nguyen, T. M., & Lam, T. K. (2022). Utilization of high volumes of copper mine tailings in the production of fine-grained concrete. Materials Today Proceedings, 65, 543–548. https://doi.org/10.1016/J.MATPR.2022.03.089

El Machi, A., Mabroum, S., Taha, Y., Tagnit-Hamou, A., Benzaazoua, M., & Hakkou, R. (2020). Valorization of phosphate mine waste rocks as aggregates for concrete. Materials Today Proceedings. https://doi.org/10.1016/j.matpr.2020.08.404

El Machi, A., Mabroum, S., Taha, Y., Tagnit-Hamou, A., Benzaazoua, M., & Hakkou, R. (2021). Use of flint from phosphate mine waste rocks as an alternative aggregates for concrete. Construction and Building Materials, 271, 121886. https://doi.org/10.1016/j.conbuildmat.2020.121886

Sedira, N., Gomes, J. C., & Luo, S. (2023). Characterisation and development of alkali-activated binders from co-utilisation of tungsten mining waste mud and electric arc furnace slag for precast applications. SSRN Electronic Journal. https://doi.org/10.2139/SSRN.4371201

Argane, R., Benzaazoua, M., Hakkou, R., & Bouamrane, A. (2016). A comparative study on the practical use of low sulfide base-metal tailings as aggregates for rendering and masonry mortars. Journal of Cleaner Production, 112, 914–925. https://doi.org/10.1016/J.JCLEPRO.2015.06.004

Mabroum, S., Moukannaa, S., el Machi, A., Taha, Y., Benzaazoua, M., & Hakkou, R. (2020). Mine wastes based geopolymers: A critical review. Cleaner Engineering and Technology, 100014. https://doi.org/10.1016/j.clet.2020.100014

Leontief, W. (1991). The economy as a circular flow. Structural Change and Economic Dynamics, 2, 181–212.

Barreiro-Gen, M., & Lozano, R. (2020). How circular is the circular economy? Analysing the implementation of circular economy in organisations. Business Strategy and the Environment, 29, 3484–3494. https://doi.org/10.1002/BSE.2590

Andersen, M. S. (2007). An introductory note on the environmental economics of the circular economy. Sustainability Science, 2, 133–140. https://doi.org/10.1007/S11625-006-0013-6

Hill, J. (2016). Circular economy and the policy landscape in the UK. In Taking stock of industrial ecology (pp. 265–274). Springer.

Ghosh, S. K. (2019). Circular economy: Global perspective. In Circular economy: Global perspective (pp. 1–452). Springer. https://doi.org/10.1007/978-981-15-1052-6/COVER

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2024 The Author(s)

About this chapter

Cite this chapter

El Machi, A., Hakkou, R. (2024). Implementation of Circular Economy Between Mining and Construction Sectors: A Promising Route to Achieve Sustainable Development Goals. In: Bahrami, A. (eds) Sustainable Structures and Buildings. Springer, Cham. https://doi.org/10.1007/978-3-031-46688-5_4

Download citation

DOI: https://doi.org/10.1007/978-3-031-46688-5_4

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-46687-8

Online ISBN: 978-3-031-46688-5

eBook Packages: EngineeringEngineering (R0)