Abstract

Industry 5.0 (I5.0) is a novel paradigm for the development and deployment of industrial applications based on Cyber-Physical Systems (CPS). It evolves Industry 4.0 in directions that exploit trustworthy human–AI interactions in human-in-the-loop scenarios. Despite the rising popularity of I5.0, there is still a lack of reference architectures (RAs) that outline the building blocks of I5.0 applications, along with the structuring principles for effectively integrating them in industrial systems. This chapter introduces a reference model for industrial applications that addresses critical elements and requirements of the I5.0, including human–robot collaboration, cybersecurity, safety, and trust. The model enhances state-of-the-art I4.0 Industrial Internet of Things (IIoT) architectures with human-centered I5.0 features and functionalities. Based on this model, the present chapter introduces a set of blueprints that could ease the development, deployment, and operation of I5.0 applications. These blueprints address technical integration, trustworthy operations, as well as the ever-important compliance to applicable regulations such as General Data Protection Regulation (GDPR) and the emerging AI Act.

You have full access to this open access chapter, Download chapter PDF

Similar content being viewed by others

Keywords

- Industry 4.0

- Industry 5.0

- Artificial Intelligence

- Trustworthy AI

- Industrial data reliability

- Security

- Reference architecture

- AI Act

1 Introduction

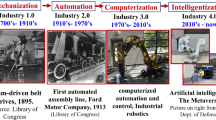

For over a decade, manufacturing enterprises are heavily investing in their digital transformation based on Cyber-Physical Production Systems (CPPS) that enable the digitization of production processing such as production scheduling, products’ assembly, physical assets’ maintenance, and quality control. The deployment and operation of CPPS in the manufacturing shopfloor is the main enabler of the fourth industrial revolution (Industry 4.0) [1], which boosts automation and efficiency toward improving production speed and quality [2], while lowering production costs and enabling novel production models such as lot-size-one manufacturing and mass customization.

Industry 4.0 applications are usually developed based on advanced digital technologies such as Big Data, Internet of Things (IoT), and Artificial Intelligence (AI), which are integrated with CPPS systems in the manufacturing shopfloor and across the manufacturing value chain. In cases of nontrivial Industry 4.0 systems, this integration can be challenging, given the number and the complexity of the systems and technology involved. For instance, sophisticated Industry 4.0 use cases are likely to comprise multiple sensors and automation devices, along with various data analytics and AI modules that are integrated in digital twins (DTs) systems and applications. To facilitate such challenging integration tasks, industrial automation solution providers are nowadays offered with access to various reference architecture models for Industry 4.0 applications. These models illustrate the functionalities and technological building blocks of Industry 4.0 applications, while at the same time documenting structuring principles that facilitate their integration and deployment in complete systems and applications. Some of these reference architecture models focus on specific aspects of Industry 4.0 such as data collection, data processing, and analytics, while others take a more holistic view that addresses multiple industrial functionalities. Moreover, several architecture models address nonfunctional requirements as well, such as the cybersecurity and safety of industrial systems.

During the last couple of years, there is a surge of interest on Industry 4.0 applications that emphasize human-centered industrial processes, i.e., processes with the human in the loop, as well as the achievement of ambitious sustainability and resilience objectives. The latter are at the very top of the policy agenda of the European Union, as reflected in the European Green Deal (EGD) and Europe’s Circular Economy Action Plan (CEAP). This has led to the introduction of the term Industry 5.0, which evolves Industry 4.0 in a direction that complements efficiency and productivity goals with societal targets, notably contributions to sustainability and the workers’ well-being [3]. Hence, Industry 5.0 targets a sustainable, human-centric, and resilient industry [4]. In this direction, Industry 4.0 systems must be enhanced with human-centric technologies that put the worker at the center of the production process, while at the same time fostering security, safety, transparency, and trustworthiness. For instance, the shift from Industry 4.0 to Industry 5.0 asks for the deployment and use of transparent, interoperable, and explainable AI systems [5], beyond black-box systems (e.g., deep neural networks) that are typically used in Industry 4.0 deployments. As another example, Industry 5.0 applications comprise technological paradigms that foster the collaboration between humans and industrial systems (e.g., co-bots), rather than systems that aim at replacing the human toward hyper-automation (e.g., fully autonomous industrial robots). Likewise, the scope of digital twins in Industry 5.0 tends to differ from Industry 4.0, as simulations and what-if analysis account for human parameters (e.g., physical characteristics, emotional status, skills) as well. Also, Industry 5.0 pays greater emphasis on nonfunctional requirements such as data protection, security, and safety when compared to Industry 4.0 that prioritizes industrial performance and accuracy.

Despite these technological differences between Industry 5.0 and Industry 4.0 systems, there is still a lack of standards, formal guidelines, and blueprints for developing, deploying, and operating Industry 5.0 systems. In most cases, manufacturers and providers of industrial automation solutions make use of conventional Industry 4.0 and blueprints, which they enhance with the required features and functionalities of their Industry 5.0 use cases at hand. We argue that this is a considerable misstep in the process of designing and implementing Industry 5.0 solutions, as it deprives architects and developers of industrial systems of the opportunity to consider Industry 5.0 functionalities and features from the early stages of the industrial systems’ development. State-of-the-art approaches to developing Industry 5.0 systems start from Industry 4.0 reference architectures and address human-centricity, sustainability, and resilience as secondary, complementary concerns rather than as indispensable requirements that must be prioritized.

Motivated by the general lack of reference architecture models for Industry 5.0 systems, this chapter introduces a reference architecture for human-centric, resilient, and sustainable industrial systems, notably digital manufacturing systems that are developed based on cutting-edge technologies such as Artificial Intelligence (AI). The reference architecture highlights the main functional and nonfunctional aspects of Industry 5.0 systems and introduces technological building blocks that can support their implementation. In this direction, the present model specifies technologies that foster human-centricity and trustworthy interactions between humans and industrial systems, such as human-centered digital twins, explainable and interpretable AI, active learning, neurosymbolic learning, and more. Emphasis is also put on technological building blocks that boost cybersecurity and safety, such as technologies for ensuring the trustworthiness of data and machine learning algorithms. Along with the specification of building blocks and structuring principles for the integration in end-to-end Industry 5.0 solutions, the chapter delineates various blueprints that can facilitate the development of Industry 5.0 use cases. The presented blueprints include guidelines for regulatory compliance in the European Union (EU), notably compliance to the European AI regulation proposal (i.e., the “AI Act”) [6].

The remainder of the chapter is structured as follows:

-

Section 2 presents related work on reference architectures (RAs) for Industry 4.0. Various RAs are briefly reviewed and their concepts that are relevant to Industry 5.0 solutions are highlighted.

-

Section 3 introduces a reference architecture for Industry 5.0 systems. A high-level model of functionalities for human-centric and resilient manufacturing is first introduced, followed by a more detailed logical architecture. Moreover, the section presents a set of technological building blocks that can support the development of real-life systems based on the presented architecture.

-

Section 4 presents a set of blueprints for developing Industry 5.0 solutions based on the presented architecture. The blueprints include guidelines and best practices for building solutions compliant to the European Regulation for AI systems.

-

Section 5 is the final and concluding section of the chapter.

2 Relevant Work

A considerable number of reference architecture models have been recently introduced to facilitate the development, integration, and deployment of Industry 4.0 applications. These include architectural models specified by standards development organizations and research initiatives. As a prominent example, the Industrial Internet Reference Architecture (IIRA) prescribes a standards-based architecture for developing, deploying, and operating Industrial Internet of Things (IIoT) systems [7]. It is destined to boost interoperability across different IoT systems and to provide a mapping on how different technologies can be exploited toward developing IIoT systems. The IIRA is described at a high level of abstraction, as it strives to have broad applicability. Its specification has been driven by the analysis of a rich collection of industrial use cases, notably use cases prescribed in the scope of the activities of the Industrial Internet Consortium (IIC). The IIRA is described based on the ISO/IEC/IEEE 42010:2011 [8] standard, which has been adopted by IIC to define its Industrial Internet Architecture Framework (IIAF). The IIRA is defined in terms of four complementary viewpoints: (1) the “business viewpoint” presents the functional modules that are destined to support the business goals of different stakeholders; (2) the “usage viewpoint” presents the way systems compliant to IIRA are used. It includes various sequences of activities involving human or logical actors, which deliver the functionality prescribed by the architecture; (3) the “functional viewpoint” presents the functional components of an IIoT system, including their structure and interrelation, as well as the interfaces and interactions between them; and (4) the “implementation viewpoint” is devoted to technologies that are used to implement the various functional components and their interactions. In the scope of the IIRA, there are also cross-cutting elements, i.e., elements and functions that are applicable to all viewpoints, including connectivity, industrial analytics, distributed data management, as well as intelligent and resilient control.

The functional viewpoints of the IIRA specify five sets of functionalities, including: (1) the “control domain,” which comprises functions conducted by industrial control and automation; (2) the “operations domain,” which deals with the management and operation of the control domain. It comprises functions for the provisioning, management, monitoring, and optimization of control domain systems and functions; (3) the “information domain,” which focuses on managing and processing data from other domains, notably from the control domain; (4) the “application domain,” which provides the application logic required to implement the various business functions; and (5) the “business domain,” which implements business logic that supports business processes and procedural activities in the scope of an IIoT system.

Overall, the IIRA provides a taxonomy of the main functional areas of industrial systems, which are relevant to Industry 5.0 systems and applications as well. The IIRA introduces a clustering of functionalities into different domains, which we will leverage in Sect. 3 toward introducing our Industry 5.0 architecture. Also, the IIRA illustrates how specific functions such as asset management and cybersecurity functions can be integrated with IIoT systems and provides insights about how to best structure the logical and implementation views of industrial architectures. The implementation view of the IIRA is based on a cloud/edge computing approach, which is also the suggested implementation approach for Industry 5.0 systems. Nevertheless, the IIRA does not include any specific provisions for human-centric industrial systems such as systems that collect and analyze information about the context of the human user toward customizing the industrial functionalities accordingly.

The Industrial Internet Security Framework (IISF) complements the IIRA with a security viewpoint for industrial systems [9]. One of the main objectives of the IISF is to prescribe the functions needed for the development, deployment, and operation of trusted IIoT. These functions are also essential for ensuring the trustworthiness of Industry 5.0 systems and their AI components in industrial environments. Thus, the structure and functions of IISF provided inspiration about how to support AI trustworthiness for industrial use cases. The IISF specifies functionalities that secure all the different elements of an industrial system such as the various communication endpoints of the system. Most of these functions can be used to boost the security and trustworthiness of Industry 5.0 systems as well, as they safeguard the operation of the networks, the data, and the data processing functions of Industry 5.0 systems. Specifically, the IISF is concerned with the five main characteristics that affect the trustworthiness of IIoT deployments, i.e., security, safety, reliability, resilience, and privacy. The framework specifies a functional viewpoint that is destined to secure IIoT systems compliant to the IIRA. To this end, the functional viewpoint specifies six interacting and complementary building blocks, which are organized in a layered fashion. The top layer comprises four security functions, namely endpoint protection, communications and connectivity protection, security monitoring and analysis, and security configuration management. Likewise, a data protection layer and a system-wide security model and policy layer are specified. Each one of the functional building blocks of the IISF can be further analyzed in more fine-grained functions such as monitoring functionalities, data analytics functionalities, and actuation functionalities. Each of these three types of functionalities include security-related functions.

One more reference architecture for industrial systems, notably for fog computing systems, was introduced by the OpenFog Consortium prior to its incorporation within the Industrial Internet Consortium in 2019 [10]. The OpenFog RA specifies the structure of large-scale fog computing system with emphasis on how fog nodes are connected to enhance the intelligence and to boost the efficiency of Industrial IoT systems. The OpenFog RA specifies some cross-cutting functionalities, which are characterized as “perspectives.” One of these perspectives deals with the security functionalities, which implies that security is applicable to all layers and use scenarios from the hardware device to the higher software layers of the architecture. As already outlined, such security functions are key to the development and deployment of trusted industrial systems of the Industry 5.0 era.

The Big Data Value Association (BDVA) has specified the structure of big data systems based on the introduction of a reference model for big data systems [11]. The model illustrates a set of modules that are commonly used in big data systems along with structuring principles that drive their integration. The BDVA reference model consists of the following layers:

-

Horizontal layers that illustrate the modules and the structure of data processing chains. The modules of data processing chains support functions such as data collection, data ingestion, data analytics, and data visualization. The horizontal layers do not map to a layered architecture, where all layers must coexist in the scope of a system. For instance, it is possible to have a data processing chain that leverages data collection and visualization collection functions without necessarily using data ingestion and data analytics functionalities. Hence, the BDVA horizontal layers can be used as building blocks to construct data pipelines for AI systems.

-

Vertical layers that deal with cross-cutting issues such as cybersecurity and trust. The latter are applicable to all functionalities of the horizontal layers. Vertical layers can be also used to specify and address nontechnical aspects such as the ever important legal and regulatory aspects of AI systems.

The horizontal and vertical layers of the reference model are used to produce concrete architectures for big data systems. There are clearly many commonalities between big data and AI systems as many AI systems (e.g., deep learning systems) are data-intensive and process large amounts of data. The BDVA RA does not, however, address functionalities that foster the development of Industry 5.0 systems, such as data quality and AI model explainability functionalities. As such it is mostly appropriate for architecting AI systems without special provisions for their trustworthiness and human centricity.

Standards-based functionalities for AI systems are also specified by the ISO/IEC JTC 1/SC 42 technical committee on Artificial Intelligence [12]. The committee has produced several standards that cover different aspects of AI systems, such as data quality for analytics and machine learning (ML) (i.e., ISO/IEC DIS 5259-1), transparency taxonomy of AI systems (i.e., ISO/IEC AWI 12792), a reference architecture of knowledge engineering (i.e., ISO/IEC DIS 5392), functional safety and AI systems (i.e., ISO/IEC CD TR 5469), as well as objectives and approaches for explainability of ML models and AI systems (i.e., ISO/IEC AWI TS 6254). As evident from the above-listed descriptive titles, the ISO/IEC JTC 1/SC 42 technical committee addresses human centricity (e.g., safety, explainability) and trustworthiness (e.g., data quality, explainability) issues for Industry 5.0 systems. Nevertheless, most of the relevant standards are under development and not yet available for practical applications and use.

In recent years, the IEEE (Institute of Electrical and Electronics Engineers) SA (Standards Association) is developing a suite of standards (i.e., standards of the IEEE 7000 family) that deal with the ethical aspects of AI systems. For instance, the IEEE 7000-2021 standard titled “IEEE Standard Model Process for Addressing Ethical Concerns during System Design” [13] specifies a process that organizations can follow to ensure that their AI systems adhere to ethical values and integrate ethical AI concepts within their systems’ development lifecycle. These standards can facilitate the development of Industry 5.0. However, they are mostly focused on development, deployment, and operational processes rather on how to structure Industry 5.0 systems.

Overall, there is a still a lack of standards-based architectures and blueprints for the development of Industry 5.0 systems. Hence, AI developers, deployers, and engineers have no easy ways to structure, design, and build nontrivial trustworthy human-centric AI systems [14].

3 Architecture for AI-Based Industry 5.0 Systems (STAR-RA)

3.1 High-Level Reference Model for AI-Based Industry 5.0 Systems

3.1.1 Overview

A high-level reference model for AI-based Industry 5.0 systems is illustrated in Fig. 1. The model specifies a set of functionalities that foster trustworthiness and safety of AI systems in-line with the mandates of Industry 5.0. It clusters Industry 5.0 functionalities in three main categories or functional domains according to the terminology of the Industrial Internet Reference Architecture (IIRA). The three domains are as follows:

-

Cybersecurity domain: This domain includes functionalities that boost the cybersecurity and cyber resilience of AI systems in industrial settings. These functionalities ensure the reliability and security of industrial data, as well as of the AI algorithms that are trained and executed based on these data. The functionalities of this domain support and reinforce the trustworthiness of the project’s functions in the other two domains.

-

Human–robot collaboration (HRC) domain: This domain provides functionalities for the trusted collaboration between human and robots. It leverages cybersecurity functionalities, while reinforcing functionalities in the safety domain. The specified functionalities aim at boosting trusted interactions between humans and AI systems in ways that yield better performance than humans or AI systems alone. In this direction, this domain leverages AI models that foster the collaboration between humans and AI systems such as active learning [15] and neurosymbolic learning (e.g., [16, 17]).

-

Safety domain: This domain comprises functionalities that ensures the safety of industrial operations, including operations that involve workers and/or automation systems. For instance, functionalities in this domain reinforce worker safety, while boosting the safe operation of AMRs (automatic mobile robots).

For each one of the functional domains, Fig. 1 presents a set of functionalities, notably functionalities that are actually implemented and validated in the context of the H2020 STAR project. These functionalities are illustrated in the following subparagraphs. Note, however, that they are by no means exhaustive, as it is possible to specify additional functionalities that boost the cybersecurity, HRC and safety of AI-based functionalities in AI systems.

Explainable AI (XAI) has a prominent role in the high-level reference model of Fig. 1. This is because XAI functionalities provide support to various functionalities of the different domains. For instance, XAI is an integral element of AI models that foster HRC such as neurosymbolic learning. Similarly, XAI can be used to identify potential attempts to tamper AI systems by altering their operations. As such XAI is positioned as a cross-cutting functionality of XAI systems. As shown in Fig. 1, machine learning platforms are among the main pillars of AI-based Industry 5.0 systems as most of the functionalities are deployed and executed over such platforms. This is, for example, the case for AI systems that implement cyber-defense strategies in the cybersecurity domain and reinforcement learning systems that detect safety zones in the safety domain.

3.1.2 Cybersecurity Domain Functionalities

Cybersecurity functionalities are key to ensuring the trustworthiness of AI systems. This is because they ensure the trustworthiness and reliability of industrial data and the AI models that are trained and developed based on these data. Moreover, they protect these systems from cybersecurity attacks that could compromise their operation and break the trust on their operation. A set of indicative functionalities that have been implemented in the STAR project include:

-

Secure networked data collection: This refers to the implementation of secure networked protocols for accessing industrial data stemming from Cyber-Physical Systems (CPS) and enterprise applications (e.g., ERP (Enterprise Resource Planning) of an industrial site. For instance, they entail the implementation of data collection probes based on secure networked protocols such as TLS (Transport Level Security) and HTTS (Secure HyperText Transport Protocol).

-

Data provenance and traceability: Data provenance and traceability of industrial data is key toward ensuring industrial data reliability. Specifically, provenance and traceability functionalities enable AI system developers to continually access properties and characteristics of the source industrial data (e.g., hash codes, statistical properties) in order to implement tamper-proof functionalities [18]. Such functionalities can be implemented for both source data and AI models built on them to help preventing their tampering by malicious actors.

-

Risk assessment and mitigation: Risk assessment and mitigation functionalities are integral to most cybersecurity systems. In the case of AI-based industrial systems, they provide the means to identify, assess, and install mitigation measures against potential cybersecurity risks. Some of these risks (e.g., data falsification) can be mitigated based on other functionalities of the cybersecurity domain (e.g., provenance and traceability).

-

Security Policies Manager: This functionality makes provision for the specification and implementation of security policies for AI systems. It is a placeholder for a wide range of policies such as authenticated and authorized access to industrial data and AI functions.

-

AI cyber-defense strategies: AI systems are subject to additional vulnerabilities and cyber-resilience risks. For example, hackers can launch data poisoning attacks that alter the data that are used for training machine learning systems toward compromising their operation (e.g., [19]). Likewise, AI systems must be robust against evasion attacks that manipulate input data toward producing errors in the operation of machine learning systems (e.g., [20]). AI cyber-defense functionality aim at mitigating and confronting such attacks based on techniques such as auditing of the training data and formal verification of the input data.

3.1.3 HRC Domain Functionalities

The list of HRC functionalities of the high-level reference model includes:

-

AI for human–robot collaboration: Beyond classical machine learning models and paradigms, there are machine learning approaches that foster the interplay between humans and AI systems to enable effective HRC. This is, for example, the case with active learning systems, where robots and ML systems can consult a human expert to deal with uncertainty during data labeling processes. Active learning approaches accelerate knowledge acquisition by AI systems, facilitate HRC, and improve the overall performance and trust of AI deployments.

-

Knowledge management and representation: The knowledge of proper representation and management of HRC processes is key to the implementation of effective human–AI interactions. In this direction, semantic modeling techniques (e.g., semantic knowledge graphs) are employed to facilitate AI systems to understand and reason over the context of the HRC process [21].

-

HMI for feedback collection and management: HRC systems involve interactions between humans and AI systems, including the provision of feedback from the human to the AI system. This is, for example, the case in the above-mentioned active learning systems where humans provide data labeling feedback to AI systems. To implement such feedback collection and management functionalities, the HRC domain includes placeholders for proper HMI (human machine interfaces) such as NLP (natural language processing) interfaces.

-

Simulated reality: Simulated reality systems enable the training of HRC systems in the scope of virtual simulated environments. They are usually linked to reinforcement learning systems that are trained in virtual rather than in real environments. Their inclusion in the reference model signals the importance of training humans for HRC functionalities in a safe environment. As such they are also enablers of functionalities in the safety domain of the AI-based Industry 5.0 reference model, such as functionalities for safety zones detection.

-

Human digital twin (HDT): This is a placeholder for human-centered digital twins, which are digital twin systems that comprise information about the characteristics and the context of the human workers [22]. HDT systems are ideal for modeling, developing, and implementing HRC systems that blend AI systems with human actors, while modeling and simulating their interactions.

3.1.4 Safety Domain Functionalities

The safety domain of the reference model outlines functionalities that are key to ensuring the safe operation of AI systems (e.g., robots) in the scope of Industry 5.0 scenarios. It identifies the following indicative but important functionalities:

-

Object localization and tracking: This functionality aims at identifying the location of objects within industrial environments, notably of moving objects such as mobile robots. The localization and tracking of such functionalities are integral elements of applications that safeguard the safe operation of robotics and AI systems in industrial environments.

-

Safety zones detection: Automation systems that move within an industrial environment (e.g., shopfloor, plant floor) must follow safe trajectories that minimize the risk of collisions between automation systems, humans, and other stationary elements of the workplace. In this direction, the detection of safety zones based on AI technologies (e.g., reinforcement learning [23]) can increase the safety of the AI systems and minimize related risks.

-

Safe automatic mobile robots: This functionality is a placeholder for systems that ensure the safe movement of automatic mobile robots. The implementation of this functionality can benefit from other functionalities of this domain such as the detection of safety zones.

-

Worker safety: Apart from ensuring the safe operation and movement of robotic systems, it is important to ensure the safety of the workers. Workers’ safety is at the heart of Industry 5.0 system that emphasize human centricity. The respective functionalities ensure that workers act within safe environments and that the emotional and physical context of the human is properly considered in the design, development, deployment, and operation of AI systems.

-

Fatigue monitoring system: Fatigue monitoring is a very prominent example of a human-centered functionality that can boost both the performance and the safety of industrial systems. It collects and analyzes information about the fatigue of the worker, which can then be used to drive the adaption of AI and Industry 5.0 systems toward a worker-centric direction.

3.2 Logical Architecture for AI-Based Industry 5.0 Systems

3.2.1 Driving Principles

Figure 2 illustrates a specific instantiation of the reference architecture model, which has been implemented in the scope of the STAR project [25] and is conveniently called STAR-RA in the scope of this chapter. The architecture is presented in the form of a logical view, which comprises functional modules along with their structure and their interactions with other systems. It can serve as a basis for implementing, deploying, and operating AI-based Industry 5.0 systems. Systems compliant to the STAR-RA aim at securing existing AI-based CPPS systems in manufacturing production lines based on a holistic approach that pursues the following principles that are fully in-line with the earlier presented high-level architecture:

-

Secure and reliable data: The STAR AI systems must operate over reliable industrial data, i.e., the architecture makes provisions for alleviating the inherent unreliability of industrial data.

-

Secure and trusted AI algorithms: Systems compliant to the STAR-RA enhance the secure operation of the AI systems and algorithms that they comprise. In this direction, they make provisions for implementing cyber-defense strategies that protect and defend AI systems from malicious security attacks. STAR-RA compliant systems focus on defenses against cybersecurity attacks. Physical security attacks may be applicable to some industrial systems (e.g., robotics systems), yet they are not address by the STAR-RA.

-

Trusted human AI interactions: The presented architectures focus on the implementation of trusted interactions between humans and AI systems. On the one hand, it ensures that AI systems are transparent and explainable to humans toward boosting their acceptance and adoption. On the other hand, it also focuses on safe and trusted interactions between humans and AI systems in HRC scenarios.

-

Safe AI systems: The architecture boosts the safety of autonomous AI systems such as mobile robots. For example, it focuses on the secure placement and movement of autonomous mobile robots (AMRs) within industrial plants.

The above listed functionalities and the logical modules that implement them can not only work independently but also in synergy with each other. For instance, reinforcement learning (RL) algorithms can be used to ensure the safe operation of AMRs, which contributes to the trusted operation of AI systems. Such RL algorithms can operate independently from other modules. However, they can also be integrated with the industrial data reliability systems of the cybersecurity domain toward ensuring that they operate over trusted and reliable industrial data. This boosts and reinforces their trustworthiness. Moreover, they can be integrated with AI-based cyber-defense strategies to ensure that they cannot be tampered or compromised by malicious parties. This is yet another measure to strengthening the trustworthiness of AI systems for safe AMR operations. Overall, when integrating and combining multiple modules of the architecture, manufacturers and system integrators can gain a multiplicative trustworthiness benefit, as one system can reinforce the other.

This architectural proposition provides the structuring principles for integrating the AI-based industrial systems of the Industry 5.0 era. However, the presented functional modules do not represent an “all-or-nothing” value proposition. Manufacturers and AI systems integrators can adopt and implement parts of the STAR-RA, i.e., specific modules of the logical architecture.

As illustrated in Fig. 2, the architecture enables the development of AI systems that receive data from the shopfloor (i.e., digital manufacturing platforms and other AI-based CPPS systems) and provide different types of AI-based services to factory (cyber)security teams and to other factory stakeholders (e.g., industrial engineers, plant managers, factory workers). The alignment of the different modules to the high-level architecture of the previous subsection is illustrated by means of their color, i.e., blue-colored modules belong to the cybersecurity domain, red-colored modules to the safety domain and green-colored to the HRC domain.

3.2.2 Logical Modules

The main modules and building blocks of the architecture are illustrated in the following subparagraphs.

3.2.2.1 Digital Manufacturing Platforms and CPPS Systems

The architecture enables the development of secure, safe, and trusted AI systems in production lines. To this end, systems compliant to the STAR-RA collect and process data from AI-based systems in the shopfloor, including machines, robotic cells, AMRs, and other digital manufacturing platforms. Industry 5.0 systems comprise various CPPS systems and digital manufacturing platforms that serve as data sources for other logical modules. The latter may also consume data from other data sources in the shopfloor such as business information systems (e.g., ERP (Enterprise Resource Planning)) and manufacturing databases (e.g., historian systems).

3.2.2.2 Industry 5.0 Applications

This building block represents different types of AI-based industrial applications such as machine learning (ML) and robotics applications. They leverage information and data sources from the shopfloor. In some cases, they are integrated with the digital manufacturing platforms as well. Other modules of the architecture collect data from them and analyze their behavior toward boosting the security and trustworthiness of their operation. AI-based Industry 5.0 applications can also be data sources that provide data to other logical modules and data-driven systems of the architecture.

3.2.2.3 Secure Networked Probes (SNP)

This building block provides a secure data collection solution that offers a real time data collection, transformation, filtering, and management services to facilitate data consumers (e.g., the AI cyber-defense module and the Security Policies Manager) in accessing the required data. For example, it can be used to collect security-related data (e.g., network, system, and solution proprietary) from monitored IoT systems and store them to detect patterns of abnormal behavior by applying simple (i.e., filtering) or more elaborate (i.e., deep learning) data processing mechanisms. The solution features specialized probes that may be deployed within the monitored IoT/CPPS system or poling services for acquiring data from shopfloor sources such as CPPS systems and digital manufacturing platforms. The module belongs to the cybersecurity domain of the high-level reference architecture.

3.2.2.4 Data Provenance and Traceability (DPT)

The DPT module belongs to the cybersecurity domain and provides the means for tracking and tracing industrial data. It interfaces to the data probes to acquire information about the industrial data of the shopfloor such as information about data types, volumes, and timestamps. Accordingly, it records this information (i.e., the metadata) about the acquired data to facilitate the detection of data abuse and data tampering attempts. Specifically, data ingested in the DPT can be queried by other modules to facilitate the validation of datasets and to ensure that the data they consume have not been falsified. In this way, the DPT module reinforces the reliability and the security of the industrial data that flow through the system.

3.2.2.5 Blockchain – Distributed Ledger Infrastructure

There are different ways for implementing a DPT infrastructure for industrial data. The STAR-RA promotes a decentralized approach, which leverages the benefits of distributed ledger technologies, i.e., a blockchain protocol. Distributed ledger infrastructures offer some advantages for industrial data provenance, such as immutable and tamper-resistant records. They also provide a comprehensive and auditable trail that records the history of data transactions, including creation, modification, and transfer events. In addition, blockchains enable the implementation of Smart Contracts (SC) over the distributed ledger infrastructure, notably SCs that are used to validate the metadata of the industrial datasets that are recorded in the blockchain. SCs enable decentralized applications that provide information about the metadata to interested modules such as the cyber-defense strategies module.

3.2.2.6 AI Cyber-Defense Strategies (ACDS)

This module implements cyber-defense strategies for AI systems, i.e., strategies that protect AI systems against adversarial attacks. These strategies operate based on access to industrial data from:

-

The AI systems (including ML systems) that must be protected from cybersecurity attacks.

-

The CPPS and digital manufacturing platforms that act as data sources.

-

The metadata of the industrial data that are managed by the DPT module and its blockchain implementation.

-

The explainable AI (XAI) module, which implements explainable AI models that illustrate and interpret the operation of various AI systems and algorithms.

The module materializes different strategies in response to attacks against AI systems. For instance, it implements cyber-defense strategies for poisoning and evasion attacks. Nevertheless, additional cyber-defense strategies can be implemented and integrated with the rest of the modules (i.e., secure networked data probes, DPT). A data integration infrastructure (e.g., based on a data bus pattern) can be used as a data exchange middleware infrastructure to facilitate data transfer and data sharing across different modules involved in the detection of a cybersecurity attacks, i.e., the DPT, the ACDS, and the SNP.

3.2.2.7 Risk Assessment and Mitigation Engine (RAME)

This module implements the security risk assessment and mitigation service of the STAR-RA in-line with the cybersecurity domain of the high-level architecture. The module assesses risk for assets associated with AI-based systems in manufacturing lines. In this direction, it interacts with the AI cyber-defense strategies modules as follows: (1) the defense strategies communicate to the RAME information about identified risks for AI assets; and (2) the RAME consumes information from the DPT to assess risks. It also offers mitigation actions for the identified risks such as changes to the configuration of a probe via the SNP module.

3.2.2.8 Security Policies Manager (SPM) – Security Policies Repository (SPR)

This module defines and configures security policies that govern the operation of the DPT, AI cyber-defense, and the RAME modules. Specifically, the module specifies security policies that provide information about the probes and data sources to be integrated, the configurations of the probes, as well as the cyber-defense strategies to be deployed. By changing the applicable policies, the SPM changes the configuration and the operation of other modules of the cybersecurity domain (e.g., DPT, RAME, ACDS). The operation of the SPM is supported by a Security Policies Repository (SPR), where policy files are persisted. Furthermore, the SPM offers a GUI (graphic user interface) to the security officers of the factory (e.g., members of CERT (computer emergency response teams)).

3.2.2.9 Machine Learning and Analytics Platform

Several modules of the architecture are based on machine learning algorithms, including deep learning and reinforcement learning. This is, for example, the case of the ACDS module, which implements AI-based defense strategies among others. Another prominent example is the XAI module, which produces explainable ML models. The machine learning and analytics platform supports the operation of these AI systems. It enables developers and users of the STAR-RA modules (i.e., data scientists, domain experts, ML engineers) not only to specify and execute ML models but also to access their metadata and outcomes. The platform interacts with modules that provide datasets for training and executing AI algorithms such as the SDP module.

3.2.2.10 Explainable Artificial Intelligence (XAI)

This module provides and executes XAI models and algorithms. It provides the means for executing different types of XAI algorithms such as algorithms for explaining deep neural networks and general-purpose algorithms (e.g., LIME – Local Interpretable Model-Agnostic Explanations) [24] that explain the outcomes of AI classifiers. As such the module is a placeholder of XAI techniques. The XAI module provides its services to several other modules that leverage explainable algorithms, such as the AI cyber-defense strategies module and the simulated reality (SR) modules.

3.2.2.11 Simulated Reality (SR)

This module simulates production settings in a virtual world with a twofold objective: (1) producing data to be used by AI algorithms, especially in cases where real-world data are not available at adequate quantities; and (2) utilizing reinforcement learning techniques in artificial settings (i.e., simulated environments) toward accelerating their convergence. SR leverages services from the XAI module, which facilitate humans to assess the appropriateness and correctness of the simulated data that are generated by the SR.

3.2.2.12 Active Learning (AL) and Neurosymbolic Learning

This module provides a placeholder for machine learning paradigms that foster HRC, i.e., modules of the HRC domain of the high-level reference architecture. Such paradigms include active learning and neurosymbolic learning, which help robots and AI systems to benefit from human expertise in the context of human in the loop industrial processes. These machine learning techniques for HRC fall in the scope of the HRC domain of the high-level architecture.

3.2.2.13 Production Processes Knowledge Base (PPKB)

This module consolidates domain knowledge about the production processes of the manufacturing environment. It is used for inferencing by the other modules such as the AL and neurosymbolic learning modules. The latter modules can interact and update the module with knowledge acquired by the humans in the scope of human-in-the-loop processes. Therefore, it also falls in the scope of the HRC domain.

3.2.2.14 AMR Safety

This module comprises RL techniques that boost the safety of AMRs in industrial environments such as manufacturing shopfloors. It provides insights on the safe placement of robots in a manufacturing environment. To this end, it incorporates functionalities such as objective localization and safety zones detection of the safety domain of the high-level architecture of Fig. 1.

3.2.2.15 Human-Centered Digital Twin

This module implements a digital twin that factors human-centered parameters (e.g., fatigue, emotional status of the worker). It is a placeholder for digital twins of human-centered processes, including AI-based processes that have the human in the loop. It interacts with the analytics platforms, the workers, and the humans’ digital models.

The HDT offers a centralized access point to exploit a wide set of workers’ related data. It leverages a digital representation of the workers, which is seamlessly integrated with production system DTs. The latter can be exploited by AI-based modules to compute complex features that, enriching the HDT, enable better decisions, and dynamically adapt automation systems behavior toward improving production performance, workers’ safety, and well-being.

3.2.2.16 Human Models – Human Digital Images

This module persists and manages data about the human worker toward supporting the construction, deployment, and operation of HDTs. They provide the means for creating and using digital representations of the workers.

3.2.2.17 Graphical User Interface (GUI) – Human Machine Interface (HMI)

This module provides a GUI interaction modality between factory workers and AI systems. It comprises visualization elements (e.g., dashboards), while enabling users to interact with the AI-based modules (e.g., provide form-based input).

3.2.2.18 Natural Language Processing (NLP)

This module enables NLP interactions between the factory users and relevant AI modules (e.g., AL modules). It is a placeholder for different NLP implementations and interfaces.

3.2.2.19 Feedback Module

This module coordinates the provision of feedback from the human worker to the AI system. It is particularly important for the implementation of human–AI systems interactions (e.g., HRC scenarios). The feedback module interfaces to some interaction module (e.g., GUI or NLP) that enables the transferring of user data to the feedback module and vice versa.

3.2.2.20 Fatigue Monitoring System

This module leverages sensors and IoT devices (e.g., electroencephalography (EEG) sensors) to collect information about the worker’s fatigue. The collected information is transferred to other modules such as the human models and the HDT.

4 Solution Blueprints for Industry 5.0 Applications

4.1 The Industry 5.0 Blueprints Concept

The STAR-RA for Industry 5.0 applications can be used to support the implementation of popular secure and trustworthy data-driven use cases in industrial environments. In this direction, selected functional modules of the STAR-RA can be deployed and operated. The specification of the modules and the information flows that can support specific HRC, cybersecurity, and safety solutions in Industry 5.0 context can be defined as blueprints over the introduced architecture. Each blueprint provides a proven way to implement trusted data processing and AI functionalities for industrial applications. Rather than having to read, browse and understand the entire STAR-RA and its low-level technical details, interested parties (e.g., solution integrators, manufacturers, researchers in industrial automation, and digital manufacturing) could consult blueprints as practical ways for enhancing the trustworthiness and regulatory compliance of their work. Following paragraphs illustrate blueprints for popular technical solutions and for the adherence of Industry 5.0 to the AI regulation proposal of the European Parliament and the Council of Europe.

4.2 Technological Solutions Blueprints

Several blueprints can be defined based on the AI cyber-defense strategies (ACDS) to support use cases for defending cybersecurity attack against AI systems. As a prominent example, Table 1 illustrates the blueprint against defending a poisoning attack, where an adversary attempts to contaminate the data used to train an AI system.

Figure 3 presents the information flow between the various components of this blueprint, as implemented in the STAR project.

As another example, Table 2 presents a blueprint for solutions that validate the integrity of industrial data. This is crucial in the scope of Industry 5.0 applications as it is a foundation for ensuring industrial data reliability. Different types of industrial data can be protected based on this blueprint, such as CPPS data and analytics results (including AI outcomes). Figure 4 illustrates the information flow between different blockchain components that implement data integrity validation blueprint.

4.3 Regulatory Compliance Blueprints

Regulatory compliance blueprints illustrate how the STAR-RA and its component could be leveraged to boost the adherence of AI solutions to the AI regulation proposal of the European Commission. In April 2021, the European Parliament and the Council of Europe presented an initial proposal for the regulation of AI systems [6]. This proposal is the first organized and structured effort to regulate AI systems worldwide. Its importance for systems deployed within Europe is particularly high, given that it lays a basis for future laws within the various EU member states. The proposal establishes a technology-neutral definition of AI systems in EU law, while presenting a risk-based classification of AI systems. The classification proposes to categorize AI systems in four general classes, ranging from unacceptable risk to no risk (i.e., risk free) systems. It also outlines the requirements and obligations associated with the deployment of systems from each one of the envisaged risk levels. For instance, “high-risk” AI systems can be authorized if and only if they meet requirements spanning the areas of transparency, explainability, data quality, and more. These obligations are significantly lower for medium- and low-risk systems.

STAR-RA includes technical components that can help AI deployers and operators to meet regulatory requirements and obligations. Different components can be used to support systems belonging to the different risk classes of the AI Act. For example, the AI Act specifies that minimal-risk systems (e.g., ML-based calculations and visualization of information about physical assets) can be deployed without essential restrictions. There are no mandatory obligations for minimal risk systems. Compliance to AI code of conduct for them is recommended, yet optional. Deployers may therefore choose to deploy one or more STAR components from the different domains of the platform (cybersecurity, human–robot collaboration, safety), as well as explainable AI components as illustrated in the relevant regulatory blueprint of Table 3.

On the other hand, when deploying a limited risk system, AI deployers must ensure that they are meeting transparency obligations. In this direction, humans must be notified of the existence of an AI system component in the loop of the industrial process. This concerns industrial processes with the human in the loop, where AI systems and human interact. It is, for example, the case of some HDT applications where industrial systems collect information about the status of the worker and adapt their operations to it. The STAR-RA includes XAI components that can help deployers meet the requirements of limited risk deployments. Deployers can optionally use other STAR components to increase the safety, security, and overall trustworthiness of the AI system (see Table 4).

Many AI systems in manufacturing and other industrial environments can be classified as being high risk. This is, for example, the case with systems involving AMRs and other types of industrial robots. In the case of high-risk systems, deployers and operators must comply with a longer list of requirements, including more stringent specifications regarding explainability, transparency, data quality, and more. To support the qualification, deployment and use of such high-risk systems, STAR-RA offers many relevant components that support data reliability, AI algorithms’ reliability, increased cybersecurity, safe human–robot collaboration, and more. The use of these systems in a high-risk AI context becomes mandatory rather than optional. This is illustrated in Table 5.

5 Conclusions

Despite the rising interest in trustworthy and human-centered Artificial Intelligence systems for Industry 5.0 deployments, existing reference architectures and blueprints for AI applications do not adequately address the development and deployment of trusted AI solutions. This chapter has introduced an architecture model that can boost the design and development of trustworthy and human-centered AI applications. It has also described few indicative blueprints for the development of technical solutions and regulatory-compliant systems in-line with the architecture.

At a high level, the presented architecture clusters functionalities in three complementary domains, including cybersecurity, human–robot collaboration, and safety. The functionalities in each one of the domains reinforce functionalities in the other domains. Moreover, the XAI components of the project are used to support functionalities in all three domains. The presented architecture and its functional modules do not present an “all or nothing” value proposition. Rather manufacturers and integrators of AI solutions in industrial environments can select subsets of components of the reference architecture to meet different sets of industrial requirements. However, the presented views of the architecture do not go down to implementation detail, but rather provide higher level structuring principles and blueprints for the implementation of trustworthy AI systems.

Some of the presented blueprints provide guidance on how to use STAR-RA components to implement systems that adhere to the mandates of the AI regulation proposal of the European Parliament and the Council of Europe. This guidance is important for companies that seek to comply with the AI Act and to demonstrate regulatory readiness. The inclusion of this chapter in this open access book aspires to raise awareness about both the technical and the regulatory aspects of trustworthy and human-centered solutions for manufacturing.

References

Soldatos, J., Lazaro, O., Cavadini, F. (eds.): The Digital Shopfloor: Industrial Automation in the Industry 4.0 Era River Publishers Series in Automation, Control and Robotics. River Publishers, Gistrup (2019) ISBN: 9788770220415, e-ISBN: 9788770220408

Christou, I., Kefalakis, N., Soldatos, J., Despotopoulou, A.: End-to-end industrial IoT platform for Quality 4.0 applications. Comput. Ind. 137, 103591. ISSN 0166-3615 (2022). https://doi.org/10.1016/j.compind.2021.103591

European Commission.: Industry 5.0 – what this approach is focused on, how it will be achieved and how it is already being implemented. European Commission. https://research-and-innovation.ec.europa.eu/research-area/industrial-research-and-innovation/industry-50_en (2023). Last accessed 26 June 2023

Nahavandi, S.: Industry 5.0—a human-centric solution. Sustainability. 11, 4371 (2019). https://doi.org/10.3390/su11164371

Dwivedi R., Dave D., Naik H., Singhal S., Omer R., Patel P., Qian B., Wen Z., Shah T., Morgan G., Ranjan R.: Explainable AI (XAI): Core ideas, techniques, and solutions. ACM Comput. Surv. 55, 9 (2023), Article 194 (September 2023), 33 pages. https://doi.org/10.1145/3561048

Proposal for a Regulation of The European Parliament and of the Council laying down harmonized rules on Artificial Intelligence (Artificial Intelligence Act) and Amending Certain Union Legislative Acts, COM/2021/206 final. https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A52021PC0206. Last accessed 26 June 2023

Industrial Internet Consortium.: The Industrial Internet Reference Architecture v 1.9. Available at: https://www.iiconsortium.org/IIRA.htm. Last accessed 26 June 2023

ISO/IEC/IEEE.: ISO/IEC/IEEE 42010:2011 Systems and software engineering – Architecture description. http://www.iso.org/iso/catalogue_detail.htm?csnumber=50508 (2011). Last accessed 26 June 2023

Industrial Internet Consortium.: The Industrial Internet Security Framework. Available at: https://www.iiconsortium.org/IISF.htm. Last accessed 26 June 2023

IEEE Standard for Adoption of OpenFog Reference Architecture for Fog Computing. IEEE Std 1934-2018, 1–176, 2 Aug 2018. https://doi.org/10.1109/IEEESTD.2018.8423800

European Big Data Value Strategic Research and Innovation Agenda, Version 4.0, October 2017. https://bdva.eu/sites/default/files/BDVA_SRIA_v4_Ed1.1.pdf. Last accessed 26 June 2023

ISO/IEC JTC 1/SC 42 Artificial intelligence. https://www.iso.org/committee/6794475.html. Last accessed 26 June 2023

IEEE Standard Model Process for Addressing Ethical Concerns during System Design. IEEE Std 7000-2021, 1–82, 15 Sept 2021. https://doi.org/10.1109/IEEESTD.2021.9536679

Rožanec, J., Novalija, I., Zajec, P., Kenda, K., Tavakoli, H., Suh, S., Veliou, E., Papamartzivanos, D., Giannetsos, T., Menesidou, S., Alonso, R., Cauli, N., Meloni, A., Reforgiato, R.D., Kyriazis, D., Sofianidis, G., Theodoropoulos, S., Fortuna, B., Mladenić, D., Soldatos, J.: Human-centric artificial intelligence architecture for industry 5.0 applications. Int. J. Prod. Res. (2022). https://doi.org/10.1080/00207543.2022.2138611

Liu, Z., Wang, J., Gong, S., Tao, D., Lu, H.: Deep reinforcement active learning for human-in-the-loop person re-identification. In: 2019 IEEE/CVF International Conference on Computer Vision (ICCV), Seoul, Korea (South), pp. 6121–6130 (2019). https://doi.org/10.1109/ICCV.2019.00622

Siyaev, A., Valiev, D., Jo, G.-S.: Interaction with industrial digital twin using neuro-symbolic reasoning. Sensors. 23, 1729 (2023). https://doi.org/10.3390/s23031729

Díaz-Rodríguez, N., Lamas, A., Sanchez, J., Franchi, G., Donadello, I., Tabik, S., Filliat, D., Cruz, P., Montes, R., Herrera, F.: EXplainable Neural-Symbolic Learning (X-NeSyL) methodology to fuse deep learning representations with expert knowledge graphs: the MonuMAI cultural heritage use case. Inf. Fusion. 79, 58–83., ISSN 1566-2535 (2022). https://doi.org/10.1016/j.inffus.2021.09.022

Soldatos, J., Despotopoulou, A., Kefalakis, N., Ipektsidis, B.: Blockchain based data provenance for trusted artificial intelligence. In: Soldatos, J., Kyriazis, D. (eds.) Trusted Artificial Intelligence in Manufacturing: A Review of the Emerging Wave of Ethical and Human Centric AI Technologies for Smart Production, pp. 1–29. Now Publishers, Norwell (2021). https://doi.org/10.1561/9781680838770.ch1

Khurana, N., Mittal, S., Piplai, A., Joshi, A.: Preventing poisoning attacks on AI based threat intelligence systems. In: In IEEE 29th International Workshop on Machine Learning for Signal Processing (MLSP), pp. 1–6 (2019). https://doi.org/10.1109/MLSP.2019.8918803

Khorshidpour, Z., Hashemi, S., Hamzeh, A.: Learning a secure classifier against evasion attack. In: IEEE 16th International Conference on Data Mining Workshops (ICDMW), pp. 295–302 (2016). https://doi.org/10.1109/ICDMW.2016.0049

Umbrico, A., Orlandini, A., Cesta, A.: An ontology for human-robot collaboration. Procedia CIRP. 93, 1097–1102 (2020)

Montini, E., Cutrona, V., Bonomi, N., Landolfi, G., Bettoni, A., Rocco, P., Carpanzano, E.: An IIoT platform for human-aware factory digital twins. Procedia CIRP. 107, 661–667., ISSN 2212-8271 (2022). https://doi.org/10.1016/j.procir.2022.05.042

Andersen, P., Goodwin, M., Granmo, O.: Towards safe reinforcement-learning in industrial grid-warehousing. Inf. Sci. 537, 467–484., ISSN 0020-0255 (2020). https://doi.org/10.1016/j.ins.2020.06.010

Ribeiro, M., Singh, S., Guestrin, C.: “Why should I trust you?”: explaining the predictions of any classifier. In: Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining (KDD ‘16), pp. 1135–1144. Association for Computing Machinery, New York (2016). https://doi.org/10.1145/2939672.2939778

Soldatos, J., Kyriazis, K. (eds.): Trusted Artificial Intelligence in Manufacturing: A Review of the Emerging Wave of Ethical and Human Centric AI Technologies for Smart Production. Now Publishers, Boston-Delft (2021). https://doi.org/10.1561/9781680838770

Acknowledgments

This work has been carried out in the H2020 STAR project, which has received funding from the European Union’s Horizon 2020 research and innovation program under grant agreement No. 956573. The authors acknowledge valuable support from all partners of the project.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2024 The Author(s)

About this chapter

Cite this chapter

Soldatos, J., Ipektsidis, B., Kefalakis, N., Despotopoulou, AM. (2024). Reference Architecture for AI-Based Industry 5.0 Applications. In: Soldatos, J. (eds) Artificial Intelligence in Manufacturing. Springer, Cham. https://doi.org/10.1007/978-3-031-46452-2_1

Download citation

DOI: https://doi.org/10.1007/978-3-031-46452-2_1

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-46451-5

Online ISBN: 978-3-031-46452-2

eBook Packages: EngineeringEngineering (R0)