Abstract

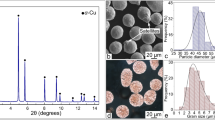

The creation of a defined surface morphology of components plays an important role in many technical applications like reduction of friction and wear or change of the adhesion of particles. In this contribution, a surface treatment process for the precise modification of the surface topology was developed on the basis of the cold spray technology. In this process, fine particles are accelerated in a gas stream by a Laval nozzle to supersonic velocities and sprayed on the surface. The particles can be embedded into the substrate surface by impact forming hills or rebound from the surface forming a crater-like surface. The influence of the process parameters on the microstructure formation was studied for fine steel and titanium particles colliding on the steel and titanium surfaces by experiments and numerical simulations. The particle acceleration in the Laval nozzle and the jet was simulated by Computational Fluid Dynamics and measured with high-speed Particle Image Velocimetry. The deposition of particles was described by a model for the critical impact velocity. The mechanical properties of surfaces and particles were measured by high temperature nanoindentation method and used for the determination of the regime diagram of the process.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Balázs BZ, Geier N, Takács M, Davim JP (2021) A review on micro-milling: recent advances and future trends. Int J Adv Manuf Technol 112:655–684

Thielen S et al (2021) Improving the tribological properties of radial shaft seal countersurfaces using experimental micro peening and classical shot peening processes. Tribol Int 155:106764

Bizi-Bandoki P, Benayoun S, Valette S, Beaugiraud B, Audouard E (2011) Modifications of roughness and wettability properties of metals induced by femtosecond laser treatment. Appl Surf Sci 257(12):5213–5218

Kwang-Seop K et al (2011) Chemical vapor deposition-grown graphene: the thinnest solid lubricant. ACS Nano 5(6):5107–5114

Waller EH, von Freymann G (2018) From photoinduced electron transfer to 3D metal microstructures via direct laser writing. Nanophotonics 7:1259–1277

Breuninger P et al (2019) Microstructuring of steel surfaces via cold spraying with 316L particles for studying the particle-wall collision behavior. Surf Coat Technol 379:125054

Breuninger P et al (2019) Microstructuring of titanium surfaces with plasma modified titanium particles by cold spraying. Particuology 44:90–104

Schmidt K et al (2017) Ti surface modification by cold spraying with TiO2 microparticles. Surf Coat Technol 309:749–758

Buhl S et al (2015) Surface structuring of case hardened chain pins by cold-sprayed micro particles to modify friction and wear properties. Particuology 21:32–40

Papyrin A, Kosarev V, Klinkov S, Alkimov A, Fomin V (2007) Cold spray technology. Elsevier

Rokni MR, Nutt SR, Widener CA, Champagne VK, Hrabe RH (2017) Review of relationship between particle deformation, coating microstructure, and properties in high-pressure cold spray. J Therm Spray Tech 26:1308–1355

Aleksieieva O et al (2022) Simulation of particle interaction with surface microdefects during cold gas-dynamic spraying. Coatings 12(9):1297

Schmidt T, Assadi H, Gärtner F et al (2009) Erratum to: from particle acceleration to impact and bonding in cold spraying. J Therm Spray Tech 18:1038

Dykhuizen RC, Smith MF (1998) Gas dynamic principles of cold spray. J Therm Spray Tech 7:205–212

Assadi H, Gärtner F, Stoltenhoff T, Kreye H (2003) Bonding mechanism in cold gas spraying. Acta Mater 51(15):4379–4394

Schmidt T, Gärtner F, Assadi H, Kreye H (2006) Development of a generalized parameter window for cold spray deposition. Acta Mater 54(3):729–742

Kliemann JO (2011) PhD Thesis. Helmut Schmidt University, Optimus Verlag, Göttingen

Yin S, Meyer M, Li W et al (2016) Gas flow, particle acceleration, and heat transfer in cold spray. J Therm Spray Tech 25:874–896

Buhl S, Breuninger P, Antonyuk S (2018) Optimization of a Laval nozzle for energy efficient cold spraying of microparticles. Mater Manuf Processes 33:115–122

Dykhuizen RC, Smith MF (1998) Gas dynamic principles of cold spray. J Therm Spray Technol 7:205

Sutherland W (2009) The London, Edinburgh, and Dublin phil. magazine, J.Sci. 36

Morsi SA, Alexander AJ (1972) An investigation of particle trajectories in two-phase flow systems. J Fluid Mech 55:193

Löffler F (1988) Staubabscheiden. Georg Thieme Verlag Stuttgart, New York

Clift R, Grace JR, Weber ME (1992) Bubbles, drops, and particles. 3. print ed., Academic Press, New York, NY

Breuninger PD (2022) Mikrostrukturierung von Stahl- und Titanoberflächen mit feindispersen Partikeln durch ein Kaltgasverfahren, PhD Thesis, TU Kaiserslautern, ISBN 978-3-95974-178-1

Assadi H et al (2015) Determination of plastic constitutive properties of microparticles through single particle compression. Adv Powder Technol 26(6):1544–1554

Fischer-Cripps AC (2004) Nanoindentation. Springer

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7:1564–1583

Weis D, Krull F, Mathy J, Evers M, Thommes M, Antonyuk S (2019) A contact model for the deformation behaviour of pharmaceutical pellets under cyclic loading. Adv Powder Technol 30:2492–2502

Hesse R, Krull F, Antonyuk S (2020) Experimentally calibrated CFD-DEM study of air impairment during powder discharge for varying hopper configurations. Powder Technol 372:404–419

Hesse R, Lösch P, Antonyuk S (2023) CFD-DEM analysis of internal packing structure and pressure characteristics in compressible filter cakes using a novel elastic-plastic contact model. Adv Powder Technol 34:104062

Acknowledgments

This research was funded by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) Project-ID AN 782/24-1 in Priority Programm 2364, and Project-ID 172116086 – SFB 926, subprojects B03, which the author gratefully acknowledges.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Antonyuk, S. (2024). Microstructuring of Component Surfaces with Fine Particles by Cold Spraying. In: Barros, J.A.O., Kaklauskas, G., Zavadskas, E.K. (eds) Modern Building Materials, Structures and Techniques. MBMST 2023. Lecture Notes in Civil Engineering, vol 392. Springer, Cham. https://doi.org/10.1007/978-3-031-44603-0_6

Download citation

DOI: https://doi.org/10.1007/978-3-031-44603-0_6

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-44602-3

Online ISBN: 978-3-031-44603-0

eBook Packages: EngineeringEngineering (R0)