Abstract

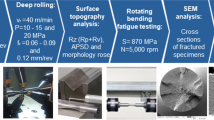

Deep Rolling as a well-known mechanical surface treatment process is investigated with the objective to tailor residual stress profiles over the sheet metal thickness. Experiments are performed in a milling portal on AA2024 aluminum alloy with a hydrostatically mounted deep rolling tool. Residual stress measurements are carried out using the hole drilling method. A numerical simulation using the finite element method (FEM) is set up and experimentally validated. One of the most effective parameters to tailor residual stresses is the deep rolling force, which is directly linked to the hydraulic tool pressure. The residual stress profiles can be described by characteristic values such as the magnitude of the maximum compressive residual stress and its penetration depth. Deep rolling modifies residual stresses not only along the material depth but also along other spatial directions.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Sticchi, M., Schnubel, D., Kashaev, N., Huber, N.: Review of residual stress modification techniques for extending the fatigue life of metallic aircraft components. Appl. Mech. Rev. 67(1) (2014)

Schijve, J.: Fatigue crack growth. Analysis and Predictions. In: Schijve, J., (eds.) Fatigue of Structures and Materials, pp. 209–256. Springer, Dordrecht (2009). https://doi.org/10.1007/978-3-319-32534-7

Altenberger, I.: Deep rolling–the past, the present and the future. In: Conference Proceeding ICSP, pp. 144–155 (2005)

Treuting, R., Read, W.: A mechanical determination of biaxial residual stress in sheet materials. J. Appl. Phys. 22(2), 130–134 (1951)

Beghini, M., Bertini, L., Monelli, B., Santus, C., Bandini, M.: Experimental parameter sensitivity analysis of residual stresses induced by deep rolling on 7075–T6 aluminium alloy. Surf. Coat. Technol. 254, 175–186 (2014)

Alasvand, K., Manouchehrifar, A.: Simulation and research on deep rolling process parameters. ADMT J. 5(5) (2012)

Denkena, B., Grove, T., Breidenstein, B., Abrão, A., Meyer, K.: Correlation between process load and deep rolling induced residual stress profiles. Procedia CIRP 78, 161–165 (2018)

Kämmler, J., Wielki, N., Meyer, D.: Surface integrity after internal load oriented multistage contact deep rolling. Procedia CIRP 71, 490–495 (2018)

Kinner-Becker, T., Sölter, J., Karpuschewski, B.: A simulation-based analysis of internal material loads and material modifications in multi-step deep rolling. Procedia CIRP 87, 515–520 (2020)

Dursun, T., Soutis, C.: Recent developments in advanced aircraft aluminium alloys. Mater. Des. 1980–2015(56), 862–871 (2014)

Schajer, G., Rickert, T.: Incremental computation technique for residual stress calculations using the integral method. Exp. Mech. 51, 1217–1222 (2011). https://doi.org/10.1007/s11340-010-9408-5

Chupakhin, S., Kashaev, N., Huber, N.: Effect of elasto-plastic material behaviour on determination of residual stress profiles using the hole drilling method. J. Strain Anal. Eng. Des. 51(8), 572–581 (2016)

Gariépy, A., Larose, S., Perron, C., Lévesque, M.: Shot peening and peen forming finite element modelling–towards a quantitative method. Int. J. Solids Struct. 48(20), 2859–2877 (2011)

Zhao, H.: A constitutive model for metals over a large range of strain rates identification for mild-steel and aluminium sheets. Mater. Sci. Eng. A 230(1–2), 95–99 (1997)

Klocke, F., Liermann, J.: Roller burnishing of hard turned surfaces. Int. J. Mach. Tools Manuf. 38(5), 419–423 (1998)

Schwab, K., Keller, S., Kashaev, N., Klusemann, B.: Tailoring of residual stresses by specific use of defined prestress during laser shock peening. J. Mater. Process. Technol. 295, 117154 (2021)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Lehmann, J., Keller, S., Esterl, F., Kashaev, N., Klusemann, B., Ben Khalifa, N. (2024). Deep Rolling for Tailoring Residual Stresses of AA2024 Sheet Metals. In: Mocellin, K., Bouchard, PO., Bigot, R., Balan, T. (eds) Proceedings of the 14th International Conference on the Technology of Plasticity - Current Trends in the Technology of Plasticity. ICTP 2023. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-41341-4_37

Download citation

DOI: https://doi.org/10.1007/978-3-031-41341-4_37

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-41340-7

Online ISBN: 978-3-031-41341-4

eBook Packages: EngineeringEngineering (R0)