Abstract

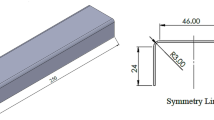

Beads are typical offset features used in sheet metal parts for increased out-of-plane bending stiffness. Incrementally forming beads using common tools presents a new paradigm for manufacturing versatility and geometrical flexibility in part design while bringing significant cost benefits for low volume applications in automotive and other industries. However, the production applications of incremental beading can be limited due to beading induced distortion and subsequent dimensional quality concerns. In this study, distortion reduction solutions are sought after based on a combined approach of virtual simulations and physical testing. Numerical models, through Finite Element Analysis, are developed to virtually describe the incremental beading process and predict the resultant distortion with the goal of improving model accuracy and reducing computational cost. The developed FEM models are validated against experimental data to serve as the basis for future virtual process optimization. Experimental approaches to effectively reduce distortion are identified during model validations. Effects of process variables are discussed.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Bowen, D.T., Russo, I.M., Cleaver, C.J., Allwood, J.M., Loukaides, E.G.: From art to part: learning from the traditional smith in developing flexible sheet metal forming processes. J. Mater. Process. Technol. 299, 117337 (2022). https://doi.org/10.1016/j.jmatprotec.2021.117337

Yang, D.Y., et al.: Flexibility in metal forming. CIRP Ann. 67, 743–765 (2018). https://doi.org/10.1016/j.cirp.2018.05.004

Duflou, J.R., et al.: Single point incremental forming: state-of-the-art and prospects. Int.J. Mater. Form. 11(6), 743–773 (2017). https://doi.org/10.1007/s12289-017-1387-y

Peng, W., Ou, H., Becker, A.: Double-sided incremental forming: a review. J. Manuf. Sci. Eng. 141 (2019). https://doi.org/10.1115/1.4043173

Yanagimoto, J., Banabic, D., Banu, M., Madej, L.: Simulation of metal forming – visualization of invisible phenomena in the digital era. CIRP Ann. 71, 599–622 (2022). https://doi.org/10.1016/j.cirp.2022.05.007

Hou, Y., Min, J., Lin, J., Liu, Z., Carsley, J.E., Stoughton, T.B.: Springback prediction of sheet metals using improved material models. Procedia Eng. 207, 173–178 (2017). https://doi.org/10.1016/j.proeng.2017.10.757

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Suarez, D., Huang, L., Wang, Hp., Solomon, J., Sigmund, N., Cao, J. (2024). Distortion Reduction in Incremental Beading. In: Mocellin, K., Bouchard, PO., Bigot, R., Balan, T. (eds) Proceedings of the 14th International Conference on the Technology of Plasticity - Current Trends in the Technology of Plasticity. ICTP 2023. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-41023-9_68

Download citation

DOI: https://doi.org/10.1007/978-3-031-41023-9_68

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-41022-2

Online ISBN: 978-3-031-41023-9

eBook Packages: EngineeringEngineering (R0)