Abstract

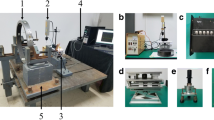

Flexible Skew Rolling (FSR) is a novel near-net-forming process for forming bars and shaft parts. This work relates to forming the GH4169 bars with FSR technology. Firstly, the finite element (FE) model was established to analyze the metal deformation characteristics in the FSR process. Furthermore, the rolling experiments was carried out. The initial microstructures of GH4169 alloy bars with and without δ-phase were obtained by Solution Treatment (ST) and Aging Treatment (AT), respectively, and the δ-phase effect on microstructure evolution of GH4169 alloy bars during FSR process was studied. The FE simulation results show that the metal spiral moves forward under the action of the rolls, completing the radial compression and axial extension. The experimental results show that the δ-phase has an important influence on the microstructure evolution of GH4169 bar. It was found that for ST workpieces and AT workpieces, the dynamic recrystallization (DRX) fraction in the middle is greater than that in the surface. This is because the surface temperature of workpiece is lower than the middle, which is not conducive to DRX. Comparing the middle part of ST and AT workpieces, it can be found that the \(\delta\) phase accelerates the DRX process. DRX has been completed in the middle part of ST workpiece, and the grain size is refined from 87 μm to about 5 μm. In addition, \(\delta\) phase also has a significant effect on the morphology of core defects. The bars obtained have good accuracy, and the diameter deviation is within ± 0.04 mm.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Ficker, T., Hardtmann, A.: Entwicklung des Axial-Vorschub-Querwalzens an der TU Dresden - ein historischer Überblick von Anfang der 1970-er Jahre bis heute (2012). (in German)

Gamin, Y.V., Akopyan, T.K., Koshmin, A.N., Dolbachev, A.P., Goncharuk, A.V.: Microstructure evolution and property analysis of commercial pure Al alloy processed by radial-shear rolling. Arch. Civil Mech. Eng. 20(4), 1 (2020). https://doi.org/10.1007/s43452-020-00143-w

Skripalenko, M.M., et al.: Forming features and properties of titanium alloy billets after radial-shear rolling. Materials 12(19), 3179–3191 (2019)

Tomczak, J., Bulzak, T., Pater, Z., Wójcik, Ł, Tomasz, K.: Skew rolling of bimetallic rods. Materials 14(1), 18–33 (2020)

Pater, Z., Tomczak, J,, Bulzak, T.: Problems of forming stepped axles and shafts in a 3-roller skew rolling mill. J. Mater. Res. Technol. 9(5), 10434–10446

Zhang, H., Wang, B., Lin, L., Feng, P., Zhou, J., Shen, J.: Numerical analysis and experimental trial of axial feed skew rolling for forming bars. Arch. Civil Mech. Eng. 22(1), 1–17 (2021). https://doi.org/10.1007/s43452-021-00334-z

Lin, L., Wang, B., Zhou, J., Shen, J.: Manufacturing large shafts by a novel flexible skew rolling process. Int. J. Adv. Manufact. Technol. 118(9–10), 2833–2851 (2021). https://doi.org/10.1007/s00170-021-08079-y

Luo, J.T., Yu, W.L., Xi, C.Y., Zhang, C.X., Ma, C.H.: Preparation of ultrafine-grained GH4169 superalloy by high-pressure torsion and analysis of grain refinement mechanism. J. Alloy. Compd. 777, 157–164 (2019)

Chen, Z.J., Lin, Y.C., He, D.G., Luo, Y.M., Chen, M.S.: A unified dislocation density-based model for an aged polycrystalline Ni-based superalloy considering the coupled effects of complicate deformation mechanisms and initial δ phase. Mater. Sci. Eng., A 827, 142062 (2021)

Wen, D.X., Lin, Y.C., Zhou, Y.: A new dynamic recrystallization kinetics model for a Nb containing Ni-Fe-Cr-base superalloy considering influences of initial δ phase. Vacuum 141, 316–327 (2017)

Zhang, H.J., et al.: Hot tensile behavior of cold-rolled inconel 718 alloy at 650°C; the role of δ phase. Mater. Sci. Eng., A 722, 136–146 (2018)

Ning, Y.Q., Huang, S.B., Fu, M.W., Dong, J.: Microstructural characterization, formation mechanism and fracture behavior of the needle δ phase in Fe–Ni–Cr type superalloys with high Nb content. Mater. Charact. 109, 36–42 (2015)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Zhang, H., Wang, B., Zhu, C., Li, Y., Yin, J. (2024). Deformation Characteristics and Microstructure Evolution of GH4169 Alloy Bars with δ-phase in Flexible Skew Rolling. In: Mocellin, K., Bouchard, PO., Bigot, R., Balan, T. (eds) Proceedings of the 14th International Conference on the Technology of Plasticity - Current Trends in the Technology of Plasticity. ICTP 2023. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-41023-9_19

Download citation

DOI: https://doi.org/10.1007/978-3-031-41023-9_19

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-41022-2

Online ISBN: 978-3-031-41023-9

eBook Packages: EngineeringEngineering (R0)