Abstract

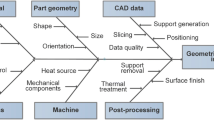

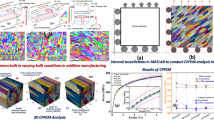

A major advantage of Additive Manufacturing (AM) processes is their ability to produce components with complex surfaces and sophisticated structures. However, several functional requirements of end-use AM parts, related to interchangeability and assemblability, are still strongly dependent on tightly toleranced Features-of-Size (FoS), as defined in current ISO-GPS standards. The paper presents an experimental approach for evaluating the dimensional and geometrical deviations of FoS produced by AM Material Extrusion processes (MEX) where the material is joined by thermal reaction bonding (MEX-TRB), such as Fused Deposition Modeling (FDM). A set of custom, primitive based test components are manufactured by low-cost and professional MEX-TRB printers, in different materials and orientations. The FoS linear and form deviations, as per ISO 14405-1 and ISO 1101, of the produced components are then evaluated by a Coordinate Measuring Machine (CMM). With the use of regression analysis, a statistical model is created, presenting and categorizing those defects. Finally, the development of a hybrid experimental/theoretical model for the prediction of linear and form deviations in MEX is presented and discussed.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

ISO/ASTM 52910: Additive manufacturing – Design - Requirements, guidelines and recommendations. International Organization for Standardization (ISO), Geneva (2018)

ISO/ASTM 52900: Additive manufacturing — General principles — Fundamentals and vocabulary. International Organization for Standardization (ISO), Geneva (2021)

Thompson, M.K., Moroni, G., Vaneker, T., et al.: Design for additive manufacturing: trends, opportunities, considerations, and constraints. CIRP Ann. Manuf. Technol. 65(2), 737–760 (2016)

Vakouftsis, C., Mavridis-Tourgelis, A., Kaisarlis, G., et al.: Effect of datum system and da-tum hierarchy on the design of functional components produced by additive manufacturing: a systematic review and analysis. Int. J. Adv. Manuf. Technol. 111, 817–828 (2020)

Nazir, A., Gokcekaya, O., Billah, K.M.M., et al.: Multi-material additive manufacturing: a systematic review of design, properties, applications, challenges, and 3D Printing of materials and cellular metamaterials. Mater. Des. 226, 111661 (2023). https://doi.org/10.1016/j.matdes.2023.111661

Beltrán, N., Blanco, D., Álvarez, B.J., et al.: Dimensional and geometrical quality enhancement in additively manufactured parts: systematic framework and a case study. Materials 12, 3937 (2019)

Gouveia, R.M., Silva, F.J.G., Atzeni, E., Sormaz, D., Alves, J.L., Pereira, A.B.: Effect of scan strategies and use of support structures on surface quality and hardness of L-PBF AlSi10Mg parts. Materials 13(10), 2248 (2020). https://doi.org/10.3390/ma13102248

Rupal, B.S., Anwer, N., Secanell, M., Jawad Qureshi, A.: Geometric tolerance and manufacturing assemblability estimation of metal additive manufacturing (AM) processes. Mater. Des. 194, 108842 (2020)

Mahmood, S., Talamona, D., Goh, K.L., Qureshi, A.J.: Fast deviation simulation for ‘fused deposition modeling’ process. Proc. CIRP 43, 327–332 (2016). https://doi.org/10.1016/j.procir.2016.02.004

Reyes-Rodríguez, A., Dorado-Vicente, R., Mayor-Vicario, R.: Dimensional and form errors of PC parts printed via fused deposition modelling. Proc. Manuf. 13, 880–887 (2017)

Zharylkassyn, B., Perveen, A., Talamona, D.: Effect of process parameters and materials on the dimensional accuracy of FDM parts. Mater. Today: Proc. 44, 1307–1311 (2021)

ISO 14405-1: Geometrical product specification (GPS) — Dimensional tolerancing — Part 1: Linear sizes. International Organization for Standardization (ISO), Geneva (2016)

ISO 1101: Geometrical product specifications (GPS) — Geometrical tolerancing — Tolerances of form, orientation, location and run-out. International Organization for Standardization (ISO), Geneva (2017)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Vakouftsis, C., Kaisarlis, G., Spitas, V., Provatidis, C.G. (2024). Experimental Research on the Dimensional and Geometrical Deviations of Features-of-Size Produced by Material Extrusion Processes. In: Silva, F.J.G., Pereira, A.B., Campilho, R.D.S.G. (eds) Flexible Automation and Intelligent Manufacturing: Establishing Bridges for More Sustainable Manufacturing Systems. FAIM 2023. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-38241-3_27

Download citation

DOI: https://doi.org/10.1007/978-3-031-38241-3_27

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-38240-6

Online ISBN: 978-3-031-38241-3

eBook Packages: EngineeringEngineering (R0)