Abstract

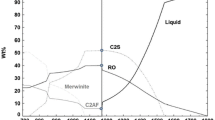

Reducing the CO2 burden of cement manufacturing can be achieved by increasing the ferrite content in cement as ferrite requires less calcium than other major clinker phases and thus reducing CO2 emission from limestone (mainly CaCO3) calcination. The steel industry produces vast and increasing amounts of EAF (electric arc furnace) slag that consists of calcium, silicon, and iron oxides from scrap steel recycling. Clinkers manufactured using EAF slag as the major component will have a higher ferrite content than traditional clinkers, as EAF slags are rich in iron. The ferrite phase is generally less reactive in polyphase than other major clinker phases; thus, accelerating ferrite hydration by adding carbonates is assessed in this study. Alite-ferrite clinker was produced from EAF slag and pure natural materials at 1450 ºC and the hydration was studied in the presence of dissolved Na2CO3, a low-cost bulk/industrial chemical that provides labile carbonate during the hydration process. The hydration kinetics at different Na2CO3 dosages and water-to-binder ratios were measured using isothermal calorimetry, and the hydrated phases were determined with TGA and XRD. The Na2CO3 dosage increased the ferrite hydration as the monocarboaluminate peak in the XRD data increased with Na2CO3 dosage. We found that there is an optimum soda ash dosage (2.5% by mass of clinker for w/b = 0.35, and 5% by mass of clinker for w/b = 0.45) to accelerate the major alite hydration peak, as confirmed from the calorimetry data and the portlandite content indirectly observed from the XRD and TGA data.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

UNEP, Emission Gap Report 2022, (2022). https://www.unep.org/resources/emissions-gap-report-2022 (Accessed December 1 2022)

Peys, A., et al.: Sustainable iron-rich cements: Raw material sources and binder types. Cem Concr Res. 157, 106834 (2022). https://doi.org/10.1016/J.CEMCONRES.2022.106834

Euroslag, Statistics 2016 - Euroslag, (n.d.). https://www.euroslag.com/products/statistics/statistics-2016/ (Accessed December 1 2022)

Li, L., Ling, T.-C., Pan, S.-Y.: Environmental benefit assessment of steel slag utilization and carbonation: A systematic review. Sci. Total Environ. 806, 150280 (2022). https://doi.org/10.1016/j.scitotenv.2021.150280

Redhammer, G.J., Tippelt, G., Roth, G., Amthauer, G.: Structural variations in the brownmillerite series Ca2(Fe2-xAlx)O5: Single-crystal X-ray diffraction at 25 °C and high-temperature X-ray powder diffraction (25 °C ≤ T ≤ 1000 °C). Am. Miner. 89, 405–420 (2004). https://doi.org/10.2138/am-2004-2-322

Chabayashi, T., Nagata, H., Nakamura, A., Kato, H.: Reduction of burning temperature of cement clinker by adjusting of mineral composition. Cement Sci. Conc. Technology. 66, 217–222 (2012). https://doi.org/10.14250/cement.66.217

Gartner, E., Myers, D.: Influence of tertiary alkanolamines on portland cement hydration. J. Am. Ceram. Soc. 76, 1521–1530 (1993). https://doi.org/10.1111/J.1151-2916.1993.TB03934.X

Hrazdira, J.: Role of superplasticizers in Gypsumless portland cements. In: American Concrete Institute, vol. SP-148, pp. 407–414. ACI Special Publication (1994). https://doi.org/10.14359/4114

Yudenfreund, M., Odler, I., Brunauer, S.: Hardened portland cement pastes of low porosity I. Materials and experimental methods, Cem Concr Res. 2, 313–330 (1972). https://doi.org/10.1016/0008-8846(72)90073-7

Huan, Z., Chang, J.: Effect of sodium carbonate solution on self-setting properties of tricalcium silicate bone cement. J Biomater Appl. 23, 247–262 (2008). https://doi.org/10.1177/0885328208088714

Wang, Y., He, F., Wang, J., Hu, Q.: Comparison of effects of sodium bicarbonate and sodium carbonate on the hydration and properties of Portland cement paste. Materials, 12 (2019). https://doi.org/10.3390/ma12071033

Zhang, T., Ma, B., Tan, H., Qi, H., Shi, T.: Effect of sodium carbonate and sodium phosphate on hydration of cement paste. J. Build. Eng. 45, 103577 (2022)

Hanein, T., Simoni, M., Woo, C.L., Provis, J.L., Kinoshita, H.: Decarbonisation of calcium carbonate at atmospheric temperatures and pressures, with simultaneous CO2 capture, through production of sodium carbonate, Energy. Environ Sci. 14, 6595–6604 (2021). https://doi.org/10.1039/D1EE02637B

Snellings, R., et al.: RILEM TC-238 SCM recommendation on hydration stoppage by solvent exchange for the study of hydrate assemblages. Mater. Struct. 51(6), 1–4 (2018). https://doi.org/10.1617/s11527-018-1298-5

Schwarz, W.: Novel cement matrices by accelerated hydration of the ferrite phase in portland cement via chemical activation: kinetics and cementitious properties. Adv. Cem. Based Mater. 2, 189–200 (1995). https://doi.org/10.1016/1065-7355(95)90003-9

Douglas, J., Dever, J.L.: Anhydrous sodium hydroxide: the heat content from Óto 700 C, the transition temperature, and the melting point. J Res Natl Bur Stand 53(1954), 81 (1934)

Goto, S., Suenaga, K., Kado, T., Fukuhara, M.: Calcium silicate carbonation products. J. Am. Ceram. Soc. 78, 2867–2872 (1995). https://doi.org/10.1111/J.1151-2916.1995.TB09057.X

Newkirk, A.E., Aliferis, I.: Drying and Decomposition of Sodium Carbonate. Anal Chem. 30, 982–984 (1958). https://doi.org/10.1021/AC60137A031/ASSET/AC60137A031.FP.PNG_V03

Jornson, D.R., Ross, W.A.: Gaylussite: Thermal Properties by Simultaneous Thermal Analysis. Am. Miner. 58, 778–784 (1973)

Acknowledgements

V. Isteri was funded by Business Finland project “Towards Carbon Neutral Metals – TOCANEM (No. 41700/31/2020)”. T. Hanein was funded by UKRI Future Leaders Fellowship (MR/V023829/1). A. Baral and T. Hanein were funded by EPSRC project, “Developing iron-rich cement clinker & understanding ferrite for the valorisation upcycling of steel slags (FeRICH)” (EP/W018810/1). The authors acknowledge Sami Liponkoski from Magsort Oy for supplying the slags used in the investigation.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Baral, A., Isteri, V., Adesanya, E., Yliniemi, J., Fabritius, T., Hanein, T. (2023). Early-Age Hydration of an EAF Slag Based Alite–Ferrite Cement Clinker in the Presence of Na2CO3. In: Jędrzejewska, A., Kanavaris, F., Azenha, M., Benboudjema, F., Schlicke, D. (eds) International RILEM Conference on Synergising Expertise towards Sustainability and Robustness of Cement-based Materials and Concrete Structures. SynerCrete 2023. RILEM Bookseries, vol 44. Springer, Cham. https://doi.org/10.1007/978-3-031-33187-9_45

Download citation

DOI: https://doi.org/10.1007/978-3-031-33187-9_45

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-33186-2

Online ISBN: 978-3-031-33187-9

eBook Packages: EngineeringEngineering (R0)