Abstract

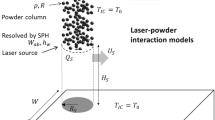

Directed Energy Distribution (DED) process involves a continuous and subsequent deposition of layers, by means of a laser heat source that melts the feedstock material supplied in form of powders or wires. Laser power, powder flow rate, travel speed affect temperature gradient distribution and residual stresses in components. Due to this, the main process parameters’ influence on DED process was investigated, followed by a fine-tuning.

The main objective of this work was to compare four simulations with different scanning strategies for the to-be-printed component, focusing on deformation results. To achieve this objective, the 3DExperience software was essential in simulating DED process accurately. Setting up the Finite Element Method (FEM) model, mesh type, material properties, and boundary conditions followed a strict procedure.

As final step, once the best case in terms of deformations from a production perspective has been highlighted, the component is subjected to post-processing machining to respect the designed dimensioning and tolerances.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Gibson, I., Rosen, D., Stucker, B.: Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing. Springer New York, New York, NY (2015). https://doi.org/10.1007/978-1-4939-2113-3

He, K., Zhao, X.: 3D thermal finite element analysis of the SLM 316L parts with microstructural correlations. Complexity 2018, 1–13 (2018). https://doi.org/10.1155/2018/6910187

Heigel, J.C., Michaleris, P., Reutzel, E.W.: Thermo-mechanical model development and validation of directed energy deposition additive manufacturing of Ti–6Al–4V. Additive Manufac. 5, 9–19 (2015). https://doi.org/10.1016/j.addma.2014.10.003

https://abaqus-docs.mit.edu/2017/English/SIMACAEGSARefMap/simagsa-m-Quasi-sb.htm

Aversa, A., Marchese, G., Bassini, E.: Directed energy deposition of AISI 316L stainless steel powder: effect of process parameters. Metals 11, 932 (2021). https://doi.org/10.3390/met11060932

Poggi, M., Vecchi, G.: Simulazioni Directed Energy Deposition Process. Politecnico di Torino, Torino

The 3DEXPERIENCE platform, a Game Changer for Business and Innovation | Dassault Systèmes (3ds.com)

Poggi, M., Pilagatti, A.N., Nonis, F.: Pianificazione degli esperimenti industriali. Politecnico di Torino, Torino

https://www.primaathome.com/images/prima/macchine/laserdyne-430/Brochure_TheADDITIVE.pdf

https://www.primaadditive.com/en/technologies/direct-energy-deposition/real-ded-laser-head

Miedzinski, M.: Materials for Additive Manufacturing by Direct Energy Deposition (2017)

Gouge, M., Michaleris, P., Denlinger, E., Irwin, J.: Thermo-Mechanical Modeling of Additive Manufacturing

https://bssa.org.uk/bssa_articles/heat-tint-temper-colours-on-stainless-steel-surface-heated-in-air/

Acknowledgement

This work has been partially supported by the award “TESUN-83486178370409 finanziamento dipartimenti di eccellenza CAP. 1694 TIT. 232 ART. 6”, which was conferred by Ministero dell'Istruzione, dell’Università e della Ricerca and by the Interdepartmental Centre for Integrated Additive Manufacturing (IAM@PoliTo) at the Politecnico di Torino, Torino, Italy.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Vallone, M., Damasio, M., Atzeni, E., Poggi, M., Salmi, A. (2023). Thermo-mechanical Modelling of the Directed Energy Deposition (DED) Process for the Optimization of Deposition Strategies. In: Lopresto, V., Papa, I., Langella, A. (eds) Dynamic Response and Failure of Composite Materials. DRAF 2022. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-28547-9_23

Download citation

DOI: https://doi.org/10.1007/978-3-031-28547-9_23

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-28546-2

Online ISBN: 978-3-031-28547-9

eBook Packages: EngineeringEngineering (R0)