Abstract

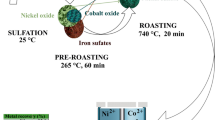

Temperature is an important factor affecting the sulfidation of laterite ore. The effect of temperature on the sulfidation of nickel in laterite ore was studied. The thermodynamic analysis shows that the sulfidation reactions of nickel oxide and iron oxide can be carried out at temperatures above 400 ºC and increasing temperature will promote the reactions. High sulfidation of nickel at high temperature will be achieved by regulating the partial pressure of sulfur and oxygen. In the atmosphere of high sulfur and low oxygen pressure, nickel and iron mainly exist in the form of sulfides. With the increase of temperature from 400 ℃ to 1200 ℃, the sulfidation degree of nickel in the ore increased initially and then decreased. At 1100 ºC, the sulfidation degree of nickel in the ore was the highest, reaching 84.43%. The size of nickel sulfide particles increased to about 10 μm.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Supriyatna YI, Sihotang IH, Sudibyo (2019) Preliminary study of smelting of Indonesian nickel laterite ore using an electric arc furnace. Mater Today Proc 13:127–131

Chen S, Guo S, Jiang L, Xu Y, Ding W (2015) Thermodynamic of selective reduction of laterite ore by reducing gases. T Nonferr Metal Soc 25(9):3133–3138

Pintowantoro S, Abdul F (2019) Selective reduction of laterite ore. Mater Trans 60(11):2245–2254

Pandey N, Tripathy S, Patra S, Jha G (2022) Recent progress in hydrometallurgical processing of nickel lateritic ore. Trans Indian Inst Metal. https://doi.org/10.1007/s12666-022-02706-2

Xu D, Liu L, Quast K, Addai-Mensah J, Robinson D (2013) Effect of nickel laterite agglomerate properties on their leaching performance. Adv Powder Technol 24(4):750–756

Quast K, Addai-Mensah J, Skinner W (2017) Preconcentration strategies in the processing of nickel laterite ores Part 5: effect of mineralogy. Miner Eng 110:31–39

Luo W, Feng Q, Ou L, Zhang G, Lu Y (2009) Fast dissolution of nickel from a lizardite-rich saprolitic laterite by sulphuric acid at atmospheric pressure. Hydrometallurgy 96(1–2):171–175

Ma B, Yang W, Yang B, Wang C, Chen Y, Zhang Y (2015) Pilot-scale plant study on the innovative nitric acid pressure leaching technology for laterite ores. Hydrometallurgy 155:88–94

Ilyas S, Srivastava R, Kim H, Ilyas N, Sattar R (2020) Extraction of nickel and cobalt from a laterite ore using the carbothermic reduction roasting-ammoniacal leaching process. Sep Purif Technol 232:115971

Gao J, Li W, Ma S, Du Z, Cheng F (2021) Spinel ferrite transformation for enhanced upgrading nickel grade in laterite ore of various types. Miner Eng 163(4):106795

Harris C, Peacey J, Pickles C (2013) Selective sulphidation and flotation of nickel from a nickeliferous laterite ore. Miner Eng 54:21–31

Harris C, Peacey J, Pickles C (2010) Selective sulphidation of a nickeliferous lateritic ore. Miner Eng 24(7):651–660

Acknowledgements

This work was supported by the Project of State Key Laboratory of Nickel and Cobalt Resources Comprehensive Utilization (738010570) and the Science and Technology Planning Project of Hunan Province, China (2019RS2008).

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Lu, S., Yu, J., Ma, Y., Zhong, Q., Rao, M., Peng, Z. (2023). Sulfidation of Nickel in Laterite Ore with Sulfur. In: Zhang, M., et al. Characterization of Minerals, Metals, and Materials 2023. TMS 2023. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-22576-5_54

Download citation

DOI: https://doi.org/10.1007/978-3-031-22576-5_54

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-22575-8

Online ISBN: 978-3-031-22576-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)