Abstract

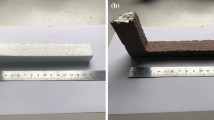

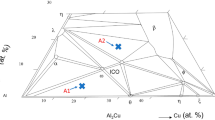

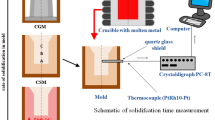

Investment casting of aluminum alloy open-pore foams requires high mold temperatures to ensure proper mold filling. The microstructural evolution of these foams is affected by the resulted slow cooling rate and the limited solidification space due to their intrinsic geometry. In our study, solidification and homogenization of investment-cast Al–Cu foams were investigated using cooling curve analysis, optical microscopy, scanning electron microscopy, and energy dispersive spectroscopy. Eutectic Al2Cu preferably precipitates around Fe-rich needle-like phases and just beneath the surface. The latter suggests that the last melt to solidify in foam casting is near the surface. Solution annealing for 16 h at 535 °C was sufficient to homogenize the Al–3.8 wt.% Cu sample but insufficient for the Al–4.8 wt.% Cu. Moreover, a 1D DICTRA model was proposed to simulate the Cu microsegregation. Simulation results agree with the experiments, and back diffusion was found to contribute slightly to homogenizing the as-cast microstructure during a relatively near-equilibrium cooling.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Gibson, LJ (1997) Cellular Solids: Structure and Properties. Cambridge University Press, Cambridge

Evans AG, Hutchinson JW, Ashby MF (1998) Cellular metals. Current Opinion in Solid State and Materials Science 3(3):288-303. https://doi.org/10.1016/S1359-0286(98)80105-8

Degischer, HP (2002) Handbook of Cellular Metals: Production, Processing, Applications. Wiley-VCH, Weinheim

Banhart J (2001) Manufacture, characterisation and application of cellular metals and metal foams. Progress in Materials Science 46(6):559-632. https://doi.org/10.1016/S0079-6425(00)00002-5

Gottstein, G (2004) Physical Foundations of Materials Science. Springer-Verlag, Berlin

Ashby, MF (2013) Engineering Materials 2 An Introduction to Microstructures and Processing. Elsevier, New York

Lumley, R (2011) Fundamentals of Aluminium Metallurgy: Production, Processing and Applications. Woodhead Publishing, Cambridge

Totten GE (ed) (2016) ASM Handbook Vol.4E–Heat Treating of Nonferrous Alloys. ASM International, Materials Park, Ohio

Kasperovich G, Volkmann T, Ratke L, Herlach D (2008) Microsegregation during Solidification of an Al-Cu Binary Alloy at Largely Different Cooling Rates (0.01 to 20,000 K/s): Modeling and Experimental Study. Metallurgical and Materials Transactions A 39(5):1183–1191. https://doi.org/10.1007/s11661-008-9505-6

Du Q, Eskin D, Jacot A, Katgerman L (2007) Two-dimensional modelling and experimental study on microsegregation during solidification of an Al-Cu binary alloy. Acta Materialia, 55(5):1523-1532. https://doi.org/10.1016/j.actamat.2006.10.035

Kraft T, Chang Y (1998) Discussion of ‘‘Effect of Dendrite Arm Coarsening on Microsegregation’’. Metallurgical and Materials Transactions A 29: 2447-2449. https://doi.org/10.1007/s11661-998-0120-3

A. Turkeli (2006) Simple analytical models for dendrite arm coarsening under high and medium temperature gradients. Materials Science Forum 508:331-336. https://doi.org/10.4028/www.scientific.net/MSF.508.331

Fischer SF, Bührig-Polaczek A (2012) Evaluation and Modification of the Block Mould Casting Process Enabling the Flexible Production of Small Batches of Complex Castings. Science and Technology of Casting Processes: 87-114. https://doi.org/10.5772/50621

Fischer SF, Schüler P, Fleck C, Bührig-Polaczek A (2013) Influence of the casting and mould temperatures on the (micro)structure and compression behaviour of investment-cast open-pore aluminium foams. Acta Materialia 61(14):5152-5161. https://doi.org/10.1016/j.actamat.2013.04.069

Zhou D, Wang J, Lu Y, Bai Z, Li X, Huang Y (2020) Optimization of Homogenization Treatment Parameters and Microstructural Evolution of Large Size DC AA2014 Aluminum Alloy. Materials Transactions 61(7):1210-1219. https://doi.org/10.2320/matertrans.MT-M2019256

Haghdadi N, Phillion A, Maijer D (2015) Microstructure Characterization and Thermal Analysis of Aluminum Alloy B206 During Solidification. Metallurgical and Materials Transactions A 46(5):2073-2081. https://doi.org/10.1007/s11661-015-2780-0

Zamani M, Toschi S, Morri A, Ceschini L, Seifeddine S (2019) Optimisation of heat treatment of Al–Cu–(Mg–Ag) cast alloys. Journal of Thermal Analysis and Calorimetry 139:3427-3440. https://doi.org/10.1007/s10973-019-08702-x

Liu X, Pan Q, Fan X, He Y, Li W, Liang W (2009) Microstructural evolution of Al-Cu-Mg-Ag alloy during homogenization. Journal of Alloys and Compounds 484(1-2):790-794. https://doi.org/10.1016/j.jallcom.2009.05.046

Sjölander E, Seifeddine S (2010) Optimisation of solution treatment of cast Al–Si–Cu alloys. Materials & Design 31(1):S44-S49. https://doi.org/10.1016/j.matdes.2009.10.035

Zamani M, Seifeddine S, Jarfors AE (2015) High temperature tensile deformation behavior and failure mechanisms of an Al–Si–Cu–Mg cast alloy — The microstructural scale effect. Materials & Design 86:361-370. https://doi.org/10.1016/j.matdes.2015.07.084

Han YM, Samuel AM, Samuel F, Valtierra S (2008) Effect of solution heat treatment type on the dissolution of copper phases in Al-Si-Cu-Mg type alloys. Transactions of the American Foundry Society 116:79-90

Li Z, Limodin N, Tandjaoui A, Quaegebeur P, Balloy D (2021) Effects of duration of solution heat treatment on the evolution of 3D microstructure in AlSi7Cu3 alloy: A quantitative X-ray tomography study. Materials Characterization 173:110919. https://doi.org/10.1016/j.matchar.2021.110919

Ågren J (2019) The Role of Diffusion in Materials. https://thermocalc.com/products/add-on-modules/diffusion-module-dictra/the-role-of-diffusion-in-materials-a-tutorial/. Accessed 10 March 2022

Borgenstam A, Höglund L, Ågren J, Engström A (2000) DICTRA, a tool for simulation of diffusional transformations in alloys. Journal of Phase Equilibria 21(3):269-280. https://doi.org/10.1361/105497100770340057

Boussinot G, Apel M (2017) Phase field and analytical study of mushy zone solidification in a static thermal gradient: From dendrites to planar front. Acta Materialia 122:310-321. https://doi.org/10.1016/j.actamat.2016.09.053

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Mohammed, W., Firoozbakht, M., Bührig–Polaczek, A. (2023). Study of the Solidification Behavior and Homogenization Heat Treatment of the Investment-Cast Al–Cu Foams: Experimental and Modelling Investigations. In: Broek, S. (eds) Light Metals 2023. TMS 2023. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-22532-1_85

Download citation

DOI: https://doi.org/10.1007/978-3-031-22532-1_85

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-22531-4

Online ISBN: 978-3-031-22532-1

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)