Abstract

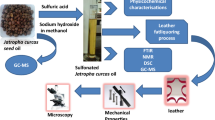

The chemical and mechanical steps in the leather-producing process—soaking, unhairing/liming, deliming/bating, pickling, tanning, neutralization/dyeing, fatliquoring, drying, and finishing—transform hides and skin into leather. The fatliquor, which is often injected into the collagen fibers to lubricate them without leaving an oily residue on the surface of the leather, is composed of many plants sulfonated oils. Plant sulfonated oil has been shown to improve the tensile strength, flexibility, and softness of leathers, as well as their lubricating capabilities. This investigation focused on the lubricating qualities of leather that had been treated with various fatliquored oils. The physicochemistry, difficulties, and potential uses of fatliquor in the manufacturing of leather were also emphasized.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Maliki M, Ifijen IH (2020) Extraction and characterization of rubber seed oil. Int’l J Sci Eng Sci 4(6):24–27

Ogbiede OK, Omorotionmwan EA, Igenumah OD, Ifijen HI, Akhigbe IU (2022) Comparative analysis on physicochemical properties and chemical composition of coconut and palm kernel oils 13(1):70–75

Ifijen IH, Maliki M, Omorogbe SO, Ibrahim SD (2022) Incorporation of metallic nanoparticles into alkyd resin: a review of their coating performance. In: The Minerals, Metals & Materials Society (eds) TMS 2022 151st annual meeting & exhibition supplemental proceedings. The Minerals, Metals & Mater. Series. Springer, Cham, pp 338–349

Ifijen IH, Maliki M, Odiachi IJ, Aghedo ON, Ohiocheoya EB (2022) Review on solvents-based alkyd resins and water borne alkyd resins: impacts of modification on their coating properties. Chem Afri 5:211–225

Ifijen IH, Nyaknno UU, Onaiwu GE, Jonathan EM, Ikhuoria EU (2022) Coating properties of alkyd resin, epoxy resins and polyurethane based nanocomposites: a review. Momona Ethiop J Sci (Accepted)

Otabor GO, Ifijen IH, Mohammed FU, Aigbodion AI, Ikhuoria EU (2019) Alkyd resin from rubber seed oil/linseed oil blend: a comparative study of the blend properties. Heliyon 5(5)15:e01621

Ifijen IH, Odi HD, Maliki M, Omorogbe SO, Aigbodion AI, Ikhuoria EU (2020) correlative studies on the properties of rubber seed and soybean oil based-alkyd resins and their blends. J Coat Technol Res 18:459–467

Nkwor AN, Ukoha PO, Ifijen HI (2021) Synthesis of sulfonated Sesamum indicum L. seed oil and its application as a fatliquor in leather processing. J. Leather Sci Eng 3(16):1–13

Nkwor AN, Ukoha PO, Ifijen HI, Ikhuoria EU (2020) The use of sulfonated jatropha curcas oil for the processing of mechanically improved leather. Chem Afri 3:911–925

Ifijen HI, Nkwor AN (2020) Selected under-exploited plant oils in Nigeria: a correlative study of their physiochemical properties. Tanz JScience 46(3):817–827

Ifijen IH, Ikhuoria EU, Omorogbe SO, Agbonlahor OG (2018) Comparative studies on the use of palm kernel and coconut oil as biodiesel fuel sources. Int’l J Green Chem 4(1):19–24

Zhou Y, Zhao W, Lai Y, Zhang B, Zhang D (2020) Edible plant oil: global status, health issues, and perspectives. Front Plant Sci 11:1315

Malik M, Ikhuoria EU, Ifijen IH (2020) Extraction and physiochemical characterization of oils obtained from selected under-utilized oil-bearing seeds in Nigeria. ChemSearch J 11(1):110–117

Wang C, Li T, Feng S(2012) Synthesis of fatliquor from palm oil and hydroxylterminated organosilicon. Asian J Chem 24:63–67

Quadery A, Uddin T, Azad A, Chowdhury M, Deb A, Hassan N (2015) Fatliquor preparation from Karanja seed oil (Pongamia pinnata L.) and its application for leather processing. IOSR J Appl Chem 8(1):54–58

Affiang S, Ggamde G, Okolo V, Olabode V, Jekkada J (2018) Synthesis of sulphated fatliquor from neem (Azadirachta indica) seed oil for leather tannag. Am J Eng Res 7(4):215–221

Zarłok J, Smiechowski K, Mucha K, Tęcza A (2014) Research on application of flax and soya oil for leather fatliquoring. J Clean Prod 65:583–589

Bajza Z, Vrček VI (2001) Fatliquoring agent and drying temperature effects on leather properties. J Mater Sci 36:5265–5270

Huang X, Kong X, Cui Y, Ye X, Wang X, Shi B (2018) Durable superhydrophobic materials enabled by abrasion-triggered roughness regeneration. Chem Eng J 336:633–639

Luo Z, Xia C, Fan H, Chen X, Peng B (2011) The biodegradabilities of different oil-based fatliquors. J Am Oil Chem Soc 88:1029–1036

Gao D, Wang P, Shi J, Li F, Li W, Lyu B, Ma J (2019) A green chemistry approach to leather tanning process: cage-like octa(aminosilsesquioxane) combined with Tetrakis (hydroxymethyl)phosphonium sulfate. J Cleaner Prod 229:1102–1111

Valeika V, Širvaitytė J, Beleška K (2010) Estimation of chrome-free tanning method suitability in conformity with physical and chemical properties of leather. Mater Sci 16(4):330

Sivakumar V, Prakash RP, Rao PG, Ramabrahmam BV, Swaminathan G (2008) Power ultrasound in fatliquor preparation based on vegetable oil for leather application 16(4):549–553

BajzaI ZZ, Vrček IV (2001) Fatliquoring agent and drying temperature effects on leather properties. J Mater Sci 36(21):5265–5270

Gutterres M, Dos Santos ML (2009) Study of fatliquoring parameters using experimental design. J Soc Leather Technol Chem 93:171–175

Nkwor AN, Ukoha PO (2020) Evaluation of the leather fatliquoring potential of sulphonated Afzelia africana aril cap oil. Heliyon 6:e03009

Yorgancioglu A, Bayramoglu EE, Renner M (2019) Preparation of antibacterial fatliquoring agents containing zinc oxide nanoparticles for leather industry. J Am Leather Chem Assoc 114:171–179

Koizhaiganova M, Yasa I, Gulumser G (2015) Assessment of antibacterial activity of lining leather treated with silver doped hydroxyapatite. Int Biodeter Biodegr 105:262–267

Sirvaityte J, Siugzdaite J, Valeikac V, Dambrauskienė E (2012) Application of essential oils of thyme as a natural preservative in leather tanning. Proc Estonian Acad Sci 61:220–227

Lkhagvajav N, Koizhaiganova M, Yasa I, Çelik E, Sari Ö (2015) Characterization and antimicrobial performance of nano silver coatings on leather materials. Braz J Microbiol 46:41–48

Yorgancioglu A, Bayramoglu EE (2013) Production of cosmetic purpose collagen containing antimicrobial emulsion with certain essential oils. Ind Crop Prod 44:378–382

Yorgancioglu A (2021) Emulsification and application of a thymol loaded antibacterial fatliquor for leather industry. J Industr Textile 51(3):470–485

Nyamunda BC, Moyo M, Chigondo F (2013) Synthesis of fatliquor from waste bovine fat for use in small scale leather industry. Indian J Chem Technol 20:116–120

Nkwor AN, Ukoha PO, Wise WR, Nwaji NN, Flowers K (2019) Fatty Acid Profile and Production of Fatliquor from Canarium schweinfurthii Mesocarp Oil. Pertanika J Sci Technol 27(4):2221–2243

Contamine F, Faid F, Wilhelm AM, Berlan J, Delmas H (1994) Chem Eng Sci 49(24B):5865–5873

Ando T, Kimura T (1990) Reactivity and selectivity in organic sonochemical reactions involving inorganic solids. Ultrasonics 28:326–332

Sivakumar V, Prakash RP, Rao PG, Ramabrahmam BV, Swaminathan G (2008) Power ultrasound in fatliquor preparation based on vegetable oil for leather application. J Cleaner Prod 16:549–553

Zhang Y, Wang L (2009) Recent research progress on leather fatliquoring agents. Polym Plast Technol Eng 48:285–291

Devikavathi G, Ramamoorthy U, Sundar V, Muralidharan C (2010) Influence of fatliquor on ageing characteristics of leather. Revista de Pielarie Incaltaminte 10:31–42

Tournier R (2015) Diagnosis, prevention and treatment of fatty spew in the tannery. J Am Leather Chem Assoc 110:260–276

Adzet J (2010) Transformation of lime split trimmings into different collagen materials. J Am Leather Chem Assoc 105:254–271

Kamely N (2022) Fatliquors for leathers: an application of microemulsion-a review. Polym Bull 79:1977–2002

Kalyanaraman C, Kanchinadham SBK, Devi LV, Porselvam S, Rao JR (2012) Combined advanced oxidation processes and aerobic biological treatment for synthetic fatliquor used in tanneries. Ind Eng Chem Res 51:16171–16181

Kalyanaraman C, Kameswari KSB, Varma VS, Tagra S, Rao JR (2013) Studies on biodegradation of vegetable-based fatliquor-containing wastewater from tanneries. Clean Technol Environ Policy 15:633–642

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Ifijen, I.H. et al. (2023). Utilization of Plant Oil-Based Fatliquor in the Processing of Leather. In: TMS 2023 152nd Annual Meeting & Exhibition Supplemental Proceedings. TMS 2023. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-22524-6_38

Download citation

DOI: https://doi.org/10.1007/978-3-031-22524-6_38

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-22523-9

Online ISBN: 978-3-031-22524-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)