Abstract

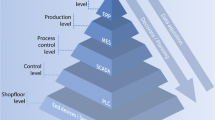

Competitiveness of an electronics manufacturing services (EMS) firm is being closely monitored and interrelated in production cost control and product reliability performance level. Data analytics in massive manufacturing data can extricate huge business opportunities and values to the firms. Major challenge in data analytics application is heterogeneous and enormous of which dynamic data generated from continuously running production line reflects real-time velocity of production environment, so that the factory management demands data analytics to provide real-time solution for the improvement right on the spot. Cloud-based data analytics exhibits problems such as data capturing, storage, transfer latency and data quality that hinders the advancement of big data analytics in smart manufacturing horizon. Selection of appropriate data mining algorithm or techniques has been challenging to industry leaders in deriving desired patterns or model solving the exact problem they are facing. The aim of this research study is to illustrate the edge-based intelligent integrated information framework (INFO-I2) for the improvement of data quality in relevancy and enabling cloud-based data analytics to focus on product performance augmentation (Pipino et al. in Commun. ACM 45:211–218, 2002 [1]). In the case study, edge devices had been used for not only real-time data collection but also localized failure analysis and predictive analytics to perform autonomous decision-making in different workstations through production process. Cloud-based computing performs efficient optimization analytics for product functionality performance with those processed data which is an integrated production management system and knowledge base generated from localized data analytics of edge devices. The implementation of edge-based information framework improves the workflow management, eventually reduces manufacturing cost and improved product reliability. The contribution of this paper is to demonstrate how the proposed cloud-based manufacturing system architecture adopted both Cloud and Edge Computing to enhance product reliability and pave the way for smart manufacturing.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Pipino, L.L., Lee, Y.W., Wang, R.Y.: Data quality assessment. Commun. ACM 45(4), 211–218 (2002). https://doi.org/10.1145/505248.506010

Fung, V.W.C., Yung, K.C.: An intelligent approach for improving printed circuit board assembly process performance in smart manufacturing. Int. J. Eng. Bus. Manag. 12, 184797902094618 (2020). https://doi.org/10.1177/1847979020946189

Liu, C., Li, H., Tang, Y., Lin, D., Liu, J.: Next generation integrated smart manufacturing based on big data analytics, reinforced learning, and optimal routes planning methods. Int. J. Comput. Integr. Manuf. 32(9), 820–831 (2019). https://doi.org/10.1080/0951192X.2019.1636412

Lee, J., Bagheri, B., Kao, H.-A.: A cyber-physical systems architecture for industry 4.0-based manufacturing systems. Manuf. Lett. 3, 18–23 (2015). https://doi.org/10.1016/j.mfglet.2014.12.001

Mazzuto, G., Ciarapica, F.E.: A big data analytics approach to quality, reliability and risk management. Int. J. Qual. Reliab. Manag. 36(1), 2–6 (2019). https://doi.org/10.1108/IJQRM-01-2019-294

Henri, J.-F., Boiral, O., Roy, M.-J.: Strategic cost management and performance: the case of environmental costs. Br. Account. Rev. 48(2), 269–282 (2016). https://doi.org/10.1016/j.bar.2015.01.001

Lee, C.K.M., Zhang, S.Z., Ng, K.K.H.: Development of an industrial internet of things suite for smart factory towards re-industrialization. Adv. Manuf. 5(4), 335–343 (2017). https://doi.org/10.1007/s40436-017-0197-2

Ren, S., Zhang, Y., Liu, Y., Sakao, T., Huisingh, D., Almeida, C.M.V.B.: A comprehensive review of big data analytics throughout product lifecycle to support sustainable smart manufacturing: a framework, challenges and future research directions. J. Clean. Prod. 210, 1343–1365 (2019). https://doi.org/10.1016/j.jclepro.2018.11.025

Qi, Q., Tao, F.: A smart manufacturing service system based on edge computing, fog computing and cloud computing. IEEE Access 1 (2019). https://doi.org/10.1109/ACCESS.2019.2923610

Hu, L., Miao, Y., Wu, G., Hassan, M.M., Humar, I.: iRobot-Factory: an intelligent robot factory based on cognitive manufacturing and edge computing. Future Gener. Comput. Syst. 90, 569–577 (2019). https://doi.org/10.1016/j.future.2018.08.006

Qu, Y.J., Ming, X.G., Liu, Z.W., Zhang, X.Y., Hou, Z.T.: Smart manufacturing systems: state of the art and future trends. Int. J. Adv. Manuf. Technol. 103(9–12), 3751–3768 (2019). https://doi.org/10.1007/s00170-019-03754-7

Shah, D., Wang, J., He, Q.P.: An internet-of-things enabled smart manufacturing testbed. IFAC-PapersOnLine 52(1), 562–567 (2019). https://doi.org/10.1016/j.ifacol.2019.06.122

Dai, H.-N., Wang, H., Xu, G., Wan, J., Imran, M., Dai, H.N., Xu, G.: Big data analytics for manufacturing internet of things: opportunities, challenges and enabling technologies. Enterp. Inf. Syst. 14 (2019). https://doi.org/10.1080/17517575.2019.1633689

Choudhary, A.K., Harding, J.A., Tiwari, M.K.: Data mining in manufacturing: a review based on the kind of knowledge. J. Intell. Manuf. 20(5), 501 (2008). https://doi.org/10.1007/s10845-008-0145-x

Varghese, B., Wang, N., Barbhuiya, S., Kilpatrick, P., Nikolopoulos, D.: Challenges and opportunities in edge computing (2016)

Xu, X., Han, M., Nagarajan, S.M., Anandhan, P.: Industrial internet of things for smart manufacturing applications using hierarchical trustful resource assignment. Comput. Commun. 160, 423–430 (2020). https://doi.org/10.1016/j.comcom.2020.06.004

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Sit, S.K.H., Lee, C.K.M. (2023). A Case Study on Data Analytics Based on Edge Computing for Smart Manufacturing System. In: Huang, CY., Dekkers, R., Chiu, S.F., Popescu, D., Quezada, L. (eds) Intelligent and Transformative Production in Pandemic Times. Lecture Notes in Production Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-18641-7_28

Download citation

DOI: https://doi.org/10.1007/978-3-031-18641-7_28

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-18640-0

Online ISBN: 978-3-031-18641-7

eBook Packages: EngineeringEngineering (R0)