Abstract

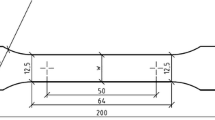

Deep drawing is a common forming method, where a sheet metal blank is drawn into a forming die by a punch. In previous research, conventional deep drawing was extended by the introduction of an additional force in the bottom of the cup. The force transmission initiates a pressure superposition in critical areas resulting in a delayed crack initiation. For numerical investigation of the considered process, an accurate modelling of the material failure is essential. Therefore, the parameters of the modified Mohr-Coulomb criterion were identified for the two high-strength steels HX340LAD and HCT600X by means of tensile tests with butterfly specimens. In this research, the fracture modelling is applied in the simulation of deep drawing with and without additional force transmission to enhance the failure prediction. The fracture criterion is validated by experimental deep drawing tests. Finally, the influence of the additional force on the prevailing stress state is evaluated.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Wifi, A., Abdelmaguid, T., El-Ghandour, A.: A review of the optimization techniques applied to the deep drawing process. In: 37th International Conference on Computers and Industrial Engineering (2007)

Kumar, D.R.: Formability analysis of extra-deep drawing steel. J. Mater. Process. Technol. 30–131, 31–41 (2002)

Merklein, M., Maren, J., Lechner, M., Kuppert, A.: A review on tailored blanks—production, applications and evaluation. J. Mater. Process. Technol. 214(2), 151–164 (2014)

Meyer, A., Wietbrock, B., Hirt, G.: Increasing of the drawing depth using tailored rolled blanks—numerical and experimental analysis. Int. J. Mach. Tools Manuf. 48(5), 522–531 (2007)

Zhang, S.H., Danckert, J.: Development of hydro-mechanical deep drawing. J. Mater. Process. Technol. 83(1–3), 14–25 (1998)

Morishita, Y., Kado, T., Abe, S., Sakamoto, Y., Yoshida, F.: Role of counterpunch for square-cup drawing of tailored blank composed of thick/thin sheets. J. Mater. Process. Technol. 212(10), 2102–2108 (2012)

Behrens, B.-A., Bonk, C., Grbic, N.,Vucetic, M.: Numerical analysis of a deep drawing process with additional force transmission for an extension of the process limits. IOP Conf. Ser. Mater. Sci. Eng. 179(1), 012006 (2017)

Behrens, B.-A., Bouguecha, A., Bonk, C., Grbic, N., Vucetic, M.: Validation of the FEA of a deep drawing process with additional force transmission. AIP Conf. Proc. 1896(1), 080024 (2017)

Behrens, B.-A., Bouguecha, A., Bonk, C., Rosenbusch, D., Grbic, N., Vucetic, M.: Influence of the determination of FLC’s and FLSC’s and their application for deep drawing process with additional force transmission. In: Proceedings of 5th International Conference on Advanced Manufacturing Engineering and Technologies, pp. 405–417 (2017)

Bai, Y., Wierzbicki, T.: Application of the extended Coulomb-Mohr model to ductile fracture. Int. J. Fract. 161(1), 1–20 (2010)

Gladkov, Y., Peshekhodov, I. A., Vucetic, M., Bouguecha, A., Behrens, B.-A.: Implementation of the Bai & Wierzbicki fracture criterion in QForm and its application for cold metal forming and deep drawing technology. In: MATEC Web of Conferences, vol. 21, pp. 12009 (2015)

Hill, R.: A theory of the yielding and plastic flow of anisotropic metals. Proc. Roy. Soc. Lond. 193(1033), 281–297 (1984)

Behrens, B.-A., Rosenbusch, D., Wester, H., Althaus, P.: Comparison of three different ductile damage models for deep drawing simulation of high-strength steels. In: IOP Conference series. Materials Science and Engineering. 1238 012021 (2022)

Merklein, M., Zöller, F., Sturm, V.: Experimental and numerical investigations on frictional behaviour under consideration of varying tribological conditions. In: Advanced Materials Research, vol. 966–967, pp. 270–278 (2014)

Acknowledgements

The results presented were obtained in the project “Extension of the forming limits during deep drawing by additional force transmission” – 212270168. The authors thank the German Research Foundation (Deutsche Forschungsgemeinschaft, DFG) for their financial support.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Althaus, P., Weichenhain, J., Hübner, S., Wester, H., Rosenbusch, D., Behrens, BA. (2023). Numerical and Experimental Failure Analysis of Deep Drawing with Additional Force Transmission. In: Liewald, M., Verl, A., Bauernhansl, T., Möhring, HC. (eds) Production at the Leading Edge of Technology. WGP 2022. Lecture Notes in Production Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-18318-8_15

Download citation

DOI: https://doi.org/10.1007/978-3-031-18318-8_15

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-18317-1

Online ISBN: 978-3-031-18318-8

eBook Packages: EngineeringEngineering (R0)