Abstract

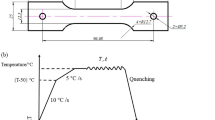

The present work investigates the effect of cold working on the fracture toughness behaviour of AA1050H16 aluminium alloy. This alloy is the popular AA1XXX aluminium alloy series used in various industrial domains (chemical, construction, electrical….) due to good formability and workability. The AA1050H16 alloy was cold worked at ambient temperature to different percentage 20%, 50% and 80% along rolling direction. According to the ASTME1820 standard, the crack-tip opening displacement at resistance curves (CTOD-R) of virgin and cold worked sheets of AA1050H16 were experimentally estimated. The central cracked panels tests specimens (CCP) were extracted from the sheets that were processed by different cold working reduction of the obtaining of CTOD-R curves. The results found that the fracture toughness of AA1050H16 aluminium alloy was influenced by cold working. With the growth of the cold working percentage the maximum loads of the load-displacement curves and the fracture toughness resistance at crack initiation (Crack Tip Opening Displacement CTOD0.2) decreased rapidly. The loss of the fracture toughness of AA1050H16 conducted to change the fracture mechanism from ductile to brittle. That is applied to the decrease of the plasticity and ductility of AA1050H16 due to the rise in the density dislocation created during the cold working process.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Rangaraju, N., Raghuram, T., Krishna, R.K.P., Venugopa, L.P.: Effect of cryo-rolling and annealing on microstructure and properties of commercially pure aluminium. Mater. Sci. Eng A 398, 246–251 (2005)

George, S., Mias, C.: Effect of rolling temperature on annealing of AA1050 aluminium alloy. Mater. Sci. Forum 828–829, 200–205 (2015)

Wang, P., Hu, S., Shen, J., Liang, Y.: Characterization the contribution and limitation of the characteristic processing parameters in cold metal transfer deposition of an Al alloy. J. Mater. Process. Technol. 245, 122–133 (2017)

Allazadeh, M.: Analysing the effect of strain rate and temperature on the flow stress in AA1050 sheet using E-2448 standard. J. Multidisc. Eng. Sci. Technol. 5(11), 9009–9015 (2018)

Ramaswamya, V., Pareeka, A., Girib, A., Anugulab, G., Srivastavab, V., Adhikar, S.: Corrosion performance evaluation of aluminum alloys for automotive applications. Presented at 16th National Congress on Corrosion Control, Kolkata, 23–25 August 2012 (2012)

Zhao, Q., Holmedal, B.: The effect of silicon on the strengthening and work hardening of aluminum at room temperature. Mater. Sci. Eng. A 563, 147–151 (2013)

Frómeta, D., et al.: Identification of fracture toughness parameters to understand the fracture resistance of advanced high strength sheet steels. Eng. Fract. Mech. 229, 106949 (2020)

Hagiwara, N., Masuda, T., Oguchi, N.: Effects of prestrain on fracture toughness and fatigue-crack growth of line pipe steels. J. Pressure Vessel Technol. 123(3), 355–361 (2001)

Madi, Y., Shinohara, Y., Besson, J.: Effect of prestrain on ductility and toughness in a high-strength line pipe steel. Int. J. Fract. 224, 15–29 (2020). https://doi.org/10.1007/s10704-020-00442-6

Kim, K., et al.: Improvement of strength and impact toughness for cold-worked austenitic stainless steels using a surface-cracking technique. Metals 8(11), 932 (2018)

Tajally, M., Zainul, H., Haji, H.M.: A comparative analysis of tensile and impact-toughness behavior of cold-worked and annealed 7075 aluminum alloy. Int. J. Impact Eng. 37(4), 425–432 (2010)

Imad, A., Wilsius, J., Abdelaziz, M.N., Mesmacque, G.: Experiments and numerical approaches to ductile tearing in an 2024-T351 aluminium alloy. Int. J. mech. Sci. 45(11), 1849–1861 (2003)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Taktak, W., Elleuch, R. (2023). Cold Working Effect on the Fracture Toughness Properties of AA1050H16 Aluminum Alloy. In: Walha, L., et al. Design and Modeling of Mechanical Systems - V. CMSM 2021. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-14615-2_100

Download citation

DOI: https://doi.org/10.1007/978-3-031-14615-2_100

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-14614-5

Online ISBN: 978-3-031-14615-2

eBook Packages: EngineeringEngineering (R0)