Abstract

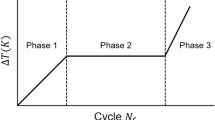

Structural integrity of mechanical devices is of fundamental importance for reliability under the action of service loads. To properly design a mechanical device against fatigue failure, a long test campaign involving many specimens and time must be performed according to traditional fatigue tests protocol. However, fatigue is a very dissipative phenomenon in which a large amount of energy is dissipated in the surrounding environment. Moving from this assumption, the adoption of infrared thermography can dramatically decrease the amount of time to obtain reliable information regarding the fatigue life of materials and components. Risitano Thermographic Method (RTM) links the superficial temperature during a fatigue test with the dissipated energy for a given stress level. The whole fatigue life of a specimen is represented by an Energy Parameter, strictly dependent on the test frequency and stress ratio, and this allow to obtain, even with one specimen, the entire fatigue curve. The Static Thermographic Method (STM) allows to assess the first damage in a specimen subjected to static tensile test by monitoring the superficial temperature evolution. The obtained limit stress could be directly related with the onset of fatigue damage within the material if cyclically stressed. The aim of the present work is to investigate the relation between the energy release and the damage at different stress ratios within a stainless steel AISI 316L, both under static tensile and fatigue tests using RTM and STM. Moreover, microstructure analysis is carried out to identify possible failure sites.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Curti, G., La Rosa, G., Orlando, M., Risitano, A.: Analisi tramite infrarosso termico della temperatura limite in prove di fatica. In: Proc XIV Convegno Naz AIAS, pp. 211–220 (1986)

Meneghetti, G.: Analysis of the fatigue strength of a stainless steel based on the energy dissipation. Int. J. Fatigue 29, 81–94 (2007). https://doi.org/10.1016/j.ijfatigue.2006.02.043

Geraci, A., La Rosa, G., Risitano, A.: L’infrarosso termico nelle applicazioni meccaniche. In: CRES Symposium, Catania Italy, pp. 8–9 (1984)

La Rosa, G., Risitano, A.: Thermographic methodology for rapid determination of the fatigue limit of materials and mechanical components. Int. J. Fatigue 22, 65–73 (2000). https://doi.org/10.1016/S0142-1123(99)00088-2

Pitarresi, G., Cappello, R., Catalanotti, G.: Quantitative thermoelastic stress analysis by means of low-cost setups. Opt. Lasers Eng. 134, 106158 (2020). https://doi.org/10.1016/j.optlaseng.2020.106158

Vergani, L., Colombo, C., Libonati, F.: A review of thermographic techniques for damage investigation in composites. Frat ed Integrita Strutt 8, 1–12 (2014). https://doi.org/10.3221/IGF-ESIS.27.01

Crupi, V., Guglielmino, E., Risitano, G., Tavilla, F.: Experimental analyses of SFRP material under static and fatigue loading by means of thermographic and DIC techniques. Compos. Part B Eng. 77, 268–277 (2015). https://doi.org/10.1016/j.compositesb.2015.03.052

Plekhov, O., Naimark, O., Semenova, I., et al.: Experimental study of thermodynamic and fatigue properties of submicrocrystalline titanium under high cyclic and gigacyclic fatigue regimes. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 229, 1271–1279 (2014). https://doi.org/10.1177/0954406214563738

Pitarresi, G., Tumino, D., Mancuso, A.: Thermo-mechanical behaviour of flax-fibre reinforced epoxy laminates for industrial applications. Materials (Basel) 8, 7371–7388 (2015). https://doi.org/10.3390/ma8115384

Foti, P., Santonocito, D., Ferro, P., et al.: Determination of fatigue limit by static thermographic method and classic thermographic method on notched specimens. Procedia Struct. Integr. 26, 166–174 (2020). https://doi.org/10.1016/j.prostr.2020.06.020

Meneghetti, G., Ricotta, M., Atzori, B.: A synthesis of the push-pull fatigue behaviour of plain and notched stainless steel specimens by using the specific heat loss. Fatigue Fract. Eng. Mater. Struct. 36, 1306–1322 (2013). https://doi.org/10.1111/ffe.12071

Meneghetti, G., Ricotta, M.: The heat energy dissipated in the material structural volume to correlate the fatigue crack growth rate in stainless steel specimens. Int. J. Fatigue 115, 107–119 (2018). https://doi.org/10.1016/j.ijfatigue.2018.07.037

Risitano, A., Risitano, G.: Determining fatigue limits with thermal analysis of static traction tests. Fatigue Fract. Eng. Mater. Struct. 36, 631–639 (2013). https://doi.org/10.1111/ffe.12030

Corigliano, P., Cucinotta, F., Guglielmino, E., et al.: Fatigue assessment of a marine structural steel and comparison with Thermographic Method and Static Thermographic Method. Fatigue Fract. Eng. Mater. Struct. 43, 734–743 (2020). https://doi.org/10.1111/ffe.13158

Risitano, G., Guglielmino, E., Santonocito, D.: Evaluation of mechanical properties of polyethylene for pipes by energy approach during tensile and fatigue tests. In: Procedia Structural Integrity, pp. 1663–1669. Elsevier B.V. (2018)

Cucinotta, F., D’Aveni, A., Guglielmino, E., et al.: Thermal emission analysis to predict damage in specimens of high strength concrete. Frat ed Integrita Strutt 15, 258–270 (2021). https://doi.org/10.3221/IGF-ESIS.55.19

Ricotta, M., Meneghetti, G., Atzori, B., et al.: Comparison of experimental thermal methods for the fatigue limit evaluation of a stainless steel. Metals (Basel) 9, 677 (2019). https://doi.org/10.3390/met9060677

Santonocito, D., Gatto, A., Risitano, G.: Energy release as a parameter for fatigue design of additive manufactured metals. Mater. Des. Process Commun. 3, 1–7 (2021). https://doi.org/10.1002/mdp2.255

Fargione, G., Geraci, A., La Rosa, G., Risitano, A.: Rapid determination of the fatigue curve by the thermographic method. Int. J. Fatigue 24, 11–19 (2002). https://doi.org/10.1016/S0142-1123(01)00107-4

Clienti, C., Fargione, G., La Rosa, G., et al.: A first approach to the analysis of fatigue parameters by thermal variations in static tests on plastics. Eng. Fract. Mech. 77, 2158–2167 (2010). https://doi.org/10.1016/j.engfracmech.2010.04.028

Stamm, H., Holzwarth, U., Boerman, D.J., et al.: Effect of laser surface treatment on high cycle fatigue of AISI 316L stainless steel. Fatigue Fract. Eng. Mater. Struct. 19, 985–995 (1996). https://doi.org/10.1111/j.1460-2695.1996.tb01034.x

Huang, H.W., Wang, Z.B., Lu, J., Lu, K.: Fatigue behaviors of AISI 316L stainless steel with a gradient nanostructured surface layer. Acta Mater. 87, 150–160 (2015). https://doi.org/10.1016/j.actamat.2014.12.057

Roland, T., Retraint, D., Lu, K., Lu, J.: Fatigue life improvement through surface nanostructuring of stainless steel by means of surface mechanical attrition treatment. Scr. Mater. 54, 1949–1954 (2006). https://doi.org/10.1016/j.scriptamat.2006.01.049

Peng, Y., Liu, Z., Chen, C., et al.: Effect of low-temperature surface hardening by carburization on the fatigue behavior of AISI 316L austenitic stainless steel. Mater. Sci. Eng. A 769, 138524 (2020). https://doi.org/10.1016/j.msea.2019.138524

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

D’Andrea, D., Guglielmino, E., Risitano, G., Santonocito, D. (2023). Rapid Determination of the Fatigue Behavior at Different Stress Ratios of Steels by Measuring the Energy Release. In: Rizzo, P., Milazzo, A. (eds) European Workshop on Structural Health Monitoring. EWSHM 2022. Lecture Notes in Civil Engineering, vol 254. Springer, Cham. https://doi.org/10.1007/978-3-031-07258-1_60

Download citation

DOI: https://doi.org/10.1007/978-3-031-07258-1_60

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-07257-4

Online ISBN: 978-3-031-07258-1

eBook Packages: EngineeringEngineering (R0)