Abstract

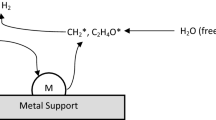

Biogas can be utilized for H2 production using steam reforming of biogas (SRB). Biogas composition varies in wide range (CH4 = 45–80%) depending on various substrates. With this view, thermodynamic modeling of steam reforming of biogas has been performed to find out the effect of change in pressure (1–11 atm), temperature (573–1273 K), biogas composition (CH4 = 45–80%), and steam-to-methane ratio (1.0–4.5) on hydrogen production. CH4 conversion of almost 99%, a high percentage of hydrogen in product gas with high H2 yield with zero carbon formation have been obtained at the temperature of 973 K and the steam-to-methane ratio of 4.0 when reformer operated at atmospheric pressure for all biogas compositions studied. Energy requirement (98.37–165.45 kJ/mol) has been determined. Besides, proton exchange membrane fuel cell (PEMFC) generates the electrical power between 129.30 and 253.09 kW from one mole of biogas having compositions between CH4/CO2 = 45/55 and 80/20, respectively.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Appari, S., Janardhanan, V., Bauri, R., Jayanti, S.: Deactivation and regeneration of Ni catalyst during steam reforming of model biogas: an experimental investigation. Int. J. Hydrogen Energy. 39(1), 297–304 (2014)

Avraam, D., Halkides, T., Liguras, D., Bereketidou, O., Goula, M.: An experimental and theoretical approach for the biogas steam reforming reaction. Int. J. Hydrogen Energy. 35(18), 9818–9827 (2010)

Chouhan, K.: Modeling of reformers for hydrogen production using renewable energy source. PhD Thesis to be submitted in December 2020. Indian Institute of Technology Roorkee, India (2020)

Effendi, A., Hellgardt, K., Zhang, Z., Yoshida, T.: Optimising H2 production from model biogas via combined steam reforming and CO shift reactions. Fuel 84(7–8), 869–874 (2005)

Galvagno, A., Chiodo, V., Urbani, F., Freni, F.: Biogas as hydrogen source for fuel cell applications. Int. J. Hydrogen Energy. 38(10), 3913–3920 (2013)

Nahar, G., Mote, D., Dupont, V.: Hydrogen production from reforming of biogas: review of technological advances and an Indian perspective. Renew. Sustain. Energy Rev. 76, 1032–1052 (2016)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Chouhan, K., Sinha, S., Kumar, S., Kumar, S. (2022). Steam Reforming of Biogas from Different Feedstocks for H2 Production and Its Use in PEMFC: Thermodynamic Analysis. In: Naddeo, V., Choo, KH., Ksibi, M. (eds) Water-Energy-Nexus in the Ecological Transition. Advances in Science, Technology & Innovation. Springer, Cham. https://doi.org/10.1007/978-3-031-00808-5_68

Download citation

DOI: https://doi.org/10.1007/978-3-031-00808-5_68

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-00807-8

Online ISBN: 978-3-031-00808-5

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)