Abstract

Due to scattering volume overlap (dependent light scattering), the efficiency of light scattering by particles embedded in crowded systems, such as paints and paper laminates, is affected by the distances between these particles and their nearest counterparts. This, in turn, is affected by particle concentration. This effect has far-reaching consequences on the opacity of systems crowded with these particles. In this chapter, we discuss different aspects of particle concentration and describe the factors that affect light scattering efficiency in crowded systems such as paints and how these factors can be controlled by the paint formulator. We will also briefly discuss the implications of dependent light scattering on paper laminate opacity.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Notes

- 1.

Of course, the two are the same if the density of the particles are the same. This is true when replacing, for example, a calcium carbonate extender with one particle size with a calcium carbonate extender of another.

- 2.

The origin of the term PVC dates to a time when it was common to call all particles added to a paint, including extender, “pigment”. Today we restrict the word “pigment” to those particles that interact with light.

- 3.

It is also unfortunate that “PVC” is often used as the acronym for polyvinyl chloride, a plastic used in high volumes worldwide.

- 4.

These values were determined by oil absorption measurements made using dioctyl phthalate oil (DOP) rather than linseed oil, which is used in a typical oil absorption test, as discussed later. This is relevant because DOP has a higher density (1.05 g/ml) than linseed oil (0.93 g/ml).

- 5.

Note that there is not a scattering volume overlap between TiO2 particles and extender particles in contact with one another since the scattering volume of an extender particle embedded in a resin does not extend outside of its physical volume, due to it having a similar refractive index to that of the surrounding resin.

- 6.

Even below this PVC, scattering volume overlap typically occurs in paints because the particle arrangement is closer to random than to ideal, and so particles can, by chance, be close to one another.

- 7.

The significance of the difference in CPVC value for the highly treated grade (approximately 45) and the universal grade (approximately 60) will be discussed in Chap. 16.

- 8.

We do this by first measuring the scattering strength of an entire paint film (see Chap. 13), and then dividing that by the number of particles in the paint, using PVC as a proxy for the number of particles.

- 9.

We define a paint system as a series of paints, made with the same particle or particle mix, that spans a range of PVC values.

- 10.

Most commercial paints have spread rate values greater than the laboratory paint used to generate Fig. 4.8. However, the laboratory paint was not optimized to give high levels of opacity, but rather was developed to best exemplify the concepts discussed here.

- 11.

The procedure for measuring the spread rate of a paint is given in Chap. 13.

- 12.

Most paints are formulated at lower PVC values than the maximum in this curve for cost reasons—even though a lower PVC film must be thicker than the film at the PVC for the maximum in this curve, the TiO2 in the film, by being at a lower PVC value, scatters light more efficiently and so less TiO2 is required per unit area covered at complete hide.

- 13.

- 14.

It is important to repeat that the laboratory paints used in these experiments were not formulated to be commercially viable, but rather to demonstrate certain principles. As such, in some cases, their behaviors cannot be directly extrapolated to those of commercial paints.

- 15.

Type 3 resin is often referred to a “free” resin, as it is not bound to the role of satisfying the resin demand of the particle mix.

- 16.

That is, the sum of the amounts of types 1 and 2 resin is the resin demand of the particles.

- 17.

Above the CPVC, type 2 resin is exchanged. In the case of extremely high PVC values, when the reservoir of type 2 resin is depleted, then type 1 resin is exchanged.

- 18.

This is true when comparing paints below the CPVC value. Small amounts of diatomaceous earth can increase paint opacity by decreasing the CPVC to a level below the paint PVC. The air voids created by the CPVC dropping below the PVC will scatter light, as discussed elsewhere in this chapter and in Chap. 3.

- 19.

A similar analysis applies to three dimensions, but this is more difficult to illustrate in figures.

- 20.

Note that we will refer to the concentration of the two-dimensional particles as if based on volume (PVC) although, technically, since this is a two-dimensional analysis, the concentration should be expressed on an area basis.

- 21.

The number of small extender particles is such that the volume of each is 25% greater than that of a TiO2 particle. In this way, there are the same number of small extender particles in the film (their concentration is 25 PVC) as are TiO2 particles (their concentration is 20 PVC).

- 22.

Here we measure efficiency on the basis of the unextended paint, not on the basis of the scattering value of the TiO2 pigment in the absence of scattering volume overlap (the basis for the analysis of Fig. 4.8).

- 23.

We consider this a worse case sample because the TiO2 PVC—25 in this case—is at the maximum in the curve for the unextended paint (i.e., the blue curve in Fig. 4.18 and elsewhere). No reasonable paint would be formulated at a TiO2 PVC above the maximum of this curve.

- 24.

Note that the two master paints must be made at the same total solid volume concentration, so that equal thicknesses of wet paint films will give equal thicknesses of dry films.

- 25.

These two components of a resin particle should not be confused with the three types of resin described earlier. Resin type describes the role that a particular portion of resin plays in a paint film while the two components describe differences in the resin particle, rather than the paint film.

- 26.

This is true only to a first approximation for scrub resistance. Pore size can also affect scrub resistance, as will be shown in Chap. 16.

- 27.

We assume that at the CPVC condition, the distances between particles on the periphery of touching agglomerates are equal to the distances between particles within the same agglomerate.

- 28.

That is, the particles are packed as tightly as possible and the voids between them filled with hydrocarbon (resin in one case, a mix of resin and mineral oil in the other).

- 29.

In some regions of the world, this is instead called the “wet hide” of the film. We discourage this use of the term “wet hide” here as the same term is often used to define the hiding ability of the freshly applied wet paint, as discussed in the next section.

- 30.

The lower end of the range of practical thickness is so thin that thickness variation due to the paint applicator (brush marks or, for roller application, stipple) results in visual non-uniformity across the wall. The upper end is dictated by the propensity of thick layers of wet paint to sag or run down vertical surfaces.

- 31.

This is seen for clear lacquers, which are quite cloudy in the liquid state but completely transparent when dry, and with paints formulated below the CPVC with extenders only (deep base paints), which are also completely transparent when dry.

- 32.

- 33.

The 0.23 micron particle is also preferred because its undertone, which is bluer than that of the larger particle, offsets the slight yellow color of many polymers (see Chap. 2 for information on pigment undertone).

References

Asbeck, W.K., Van Loo, M.: Critical Pigment Volume Relationships. Ind. Eng. Chem. 7, 1470 (1949)

Berryman, G.: Random Close Packing of Hard Spheres and Disks. Phys. Rev. A 27, 1053 (1983)

Takemura, K: Gibbsite Type Aluminum Hydroxide Particles having High Oil Absorption”, US 7,438,977 (2008)

Stieg, F.B.: Are Conventional Trade Sales Formulating Practices Wasteful? J. Coat. Technol. 48(612), 51 (1976)

Stieg, F. B., “The Coatings Industry Looks at Fillers”, Am. Chem. Soc. Div. Org. Coatings Plast. Chem., 33(3), 5 (1973)

Diebold, M. P.; Application of Light Scattering to Coatings, Springer (2014)

Auger, J.C., Stout, B.: Dependent Light Scattering in White Paint Films: Clarification and Application of Theoretical Aspects. J. Coat. Technol. Res. 9(3), 287 (2012)

Stieg, F. B., “The Effect of Extenders on the Hiding Power of Titanium Pigments”, Off. Digest, 52 (January, 1959)

Stieg, F.B.: Effect of extender on crowding of titanium pigment. J. Coat. Technol. 61(778), 67 (1989)

Cutrone, L.: Influence of Fine-Particle Size Extenders on the Optical Properties of Latex Paints. J. Coat. Technol. 58(736), 83 (1986)

Bierwagen, G.P., Rich, D.C.: The critical pigment volume concentration in latex coatings. Prog. Org. Coat. 11, 339 (1983)

Asbeck, W.K.: Critical pigment volume concentration measurements, a very fast method. CoatingsTech, 2(12) (2005)

“Standard Test Method for Oil Absorption of Pigments by Spatula Rub-out”, ASTM D281 (2016)

Stieg, F.B.: Air as a Dispersion Medium. Ind. Eng. Prod. Res. Develop. 13(1), 41 (1974)

De Backer, S.; Diebold, M. P., “Influence of Paint Quality on the Environmental Footprint of Architectural Paints”, Euro. Coat. J., 30 (Jan 2022)

Dollani, H., Elton-Legrix, A.: Coverage Uncovered. Europ. Coat. J. 10, 40 (2021)

Author information

Authors and Affiliations

Appendix

Appendix

In this appendix, we will show the process for modeling the strength of TiO2 scattering in paint films that contain large extender particles based on the scattering that we see for the same TiO2 particles in an unextended paint. This allows us to predict the expected opacities of extended paints based on the measured opacities of unextended paints.

Basis for the model:

The opacity of a paint containing only TiO2 and resin (which we will refer to as an “unextended paint”) is invariably greater than that of a similar paint for which a portion of resin has been replaced by large extender (which we will refer to as an “extended paint”). The opacity penalty for the extended paint is due to the loss of scattering efficiency per TiO2 particle because the extender particles crowd the TiO2 particles together, as discussed in the text.

It is useful to have a means of describing the degree of TiO2 crowding in a paint. An obvious way would be by the TiO2 concentration—the higher the TiO2 concentration, the greater the crowding. We can therefore describe the degree of TiO2 crowding in an extended paint with a certain PVC value based on the PVC value that would give the same degree of crowding in an unextended paint. As discussed in the text, the effective PVC describes this degree of crowding. For example, a paint with an actual TiO2 PVC of 20 and large extender PVC of 40 would have an effective TiO2 PVC of 33.3, as calculated by Eq. 4.9 in the text. This means that the scattering efficiency of the TiO2 particles in the extended paint (at 20 PVC TiO2) is the same as the scattering efficiency that the TiO2 particles would have in an unextended paint at 33.3 PVC TiO2. Note that the opacity of the extended paint at 20 PVC TiO2 will not be the same as the opacity of the unextended paint at 33.3 PVC TiO2 (i.e., at the effective PVC) because, although the TiO2 particles experience the same amount of crowding, there are more of them present in the unextended paint (since it is at a higher PVC).

In our model, we will develop a way to modify the opacities of the unextended paints by decreasing the scattering strength of each TiO2 particle to reflect the opacity penalty of extender crowding in the extended paints.

Developing the model:

To demonstrate how this model can be developed, we will use the opacities of an unextended paint system to estimate the opacities of a paint system with 20 PVC large extender.

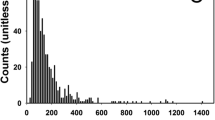

The model is based on experimentally determined opacity data for the unextended paint system. The first step in this process is to measure the spread rate (or another opacity indicator) of a series of unextended paints that span a range of TiO2 values. Data for the paint system with the universal grade of TiO2 that are shown in this chapter are given in the second column of Table 4.2 and plotted in Fig. 4.28.

Next, a measure of the scattering strengths per individual TiO2 particle in these paints is calculated by dividing the spread rate (a measure of total scattering) by the TiO2 PVC (a measure of number of TiO2 particles). This is shown for the unextended paint in the third column in Table 4.2 and as the blue line and symbols in Fig. 4.29.

The best fit equation for this particular set of data is

We next calculate the expected line for the paint series with 20 PVC large particle extender. To do this we will define a factor F that is the ratio of the reciprocal of one minus the extender PVC when expressed as a fraction. In this case, F equals 1.25 (=\(\frac{1}{1 - 0.2}\)). Multiplying the actual TiO2 PVC of the extended paints by factor F gives the effective TiO2 PVC:

Because the scattering per unit concentration is linear with PVC, we can calculate the scattering per particle for the extended paint series as simply the scattering per particle at the effective TiO2:

This equation is shown as the red line in Fig. 4.29. We can use this line to predict the opacity values for the extended paints as a function of PVC by multiplying the scattering per unit concentration for the TiO2 particles in the extended paints, as expressed in the equation above, by the actual TiO2 PVC (that is, reversing the procedure used to develop Fig. 4.29 from Fig. 4.28). The results of this calculation are shown in Fig. 4.30.

This model is useful for calculating the expected opacity of paints made with extenders based on the opacity of paints made without extenders. In some situations, we may wish to do the reverse, that is, we may have measured the opacity versus TiO2 PVC curve for a paint system that has extender in it and wish to calculate the opacity that the paints would have without the extender. One way of doing this is the reverse of the procedure discussed above, that is, to calculate the best fit line for the scattering per unit concentration for the extended paints, then adjust the slope of the line based on the effective TiO2 PVC.

There is a second way to accomplish this task. To demonstrate this, we begin by plotting one data point from the opacity versus PVC curve for the extended paint that has 20 PVC large extender and 25 PVC TiO2. This is shown as a red triangle in Fig. 4.31. We can extend a line from the origin, through this data point, and to the TiO2 PVC of 31.25 (blue circle in Fig. 4.31). This PVC is the effective PVC value of the paint and was arrived at by multiplying the actual PVC (PVC = 25) by factor F (1.25 in this case).

As explained in the text, all data points on the line going through the origin have the same TiO2 scattering strength. The blue circle, therefore, indicates the same TiO2 scattering strength as the unextended paint would have at a PVC of 31.25, and so this point will be a point on the curve for the unextended paint. For reference, this circle is indicated as a green star in Fig. 4.30.

We can repeat this process for any paint in the extended paint series to recreate the blue line in Fig. 4.30. However, in this case, the X-axis will be the effective PVC of the extended paint, rather than its actual PVC (note that the effective PVC values for the unextended paints equal their actual PVC). This is how Fig. 4.13b was created.

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Diebold, M., Backer, S.D., Niedenzu, P.M., Hester, B.R., Vanhecke, F.A.C. (2022). Light Scattering 2—Light Scattering in Crowded Systems. In: Pigments, Extenders, and Particles in Surface Coatings and Plastics. Springer, Cham. https://doi.org/10.1007/978-3-030-99083-1_4

Download citation

DOI: https://doi.org/10.1007/978-3-030-99083-1_4

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-99082-4

Online ISBN: 978-3-030-99083-1

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)